REMOVAL:

1.Disconnect the unit from the power source.

2.Tip the unit over and remove the drive belt.

3.Remove the dust cap from the under side of pulley.

4.Remove retaining ring and washer from end of drive shaft.

5.Firmly pull lower cam off the drive shaft splines, then slide the other parts off the shaft. This will also allow access to the brake assembly for removal.

REASSEMBLY:

After reassembling the components on the drive shaft, it will probably be neces- sary to pull down on the shaft to take the end play out of it before the thrust washer and retaining ring can be reinstalled.

NOTE: Each time the cams are reas- sembled on the drive shaft, the point in the cam rise where the brake disengages the stator should be checked and ad- justed as necessary.

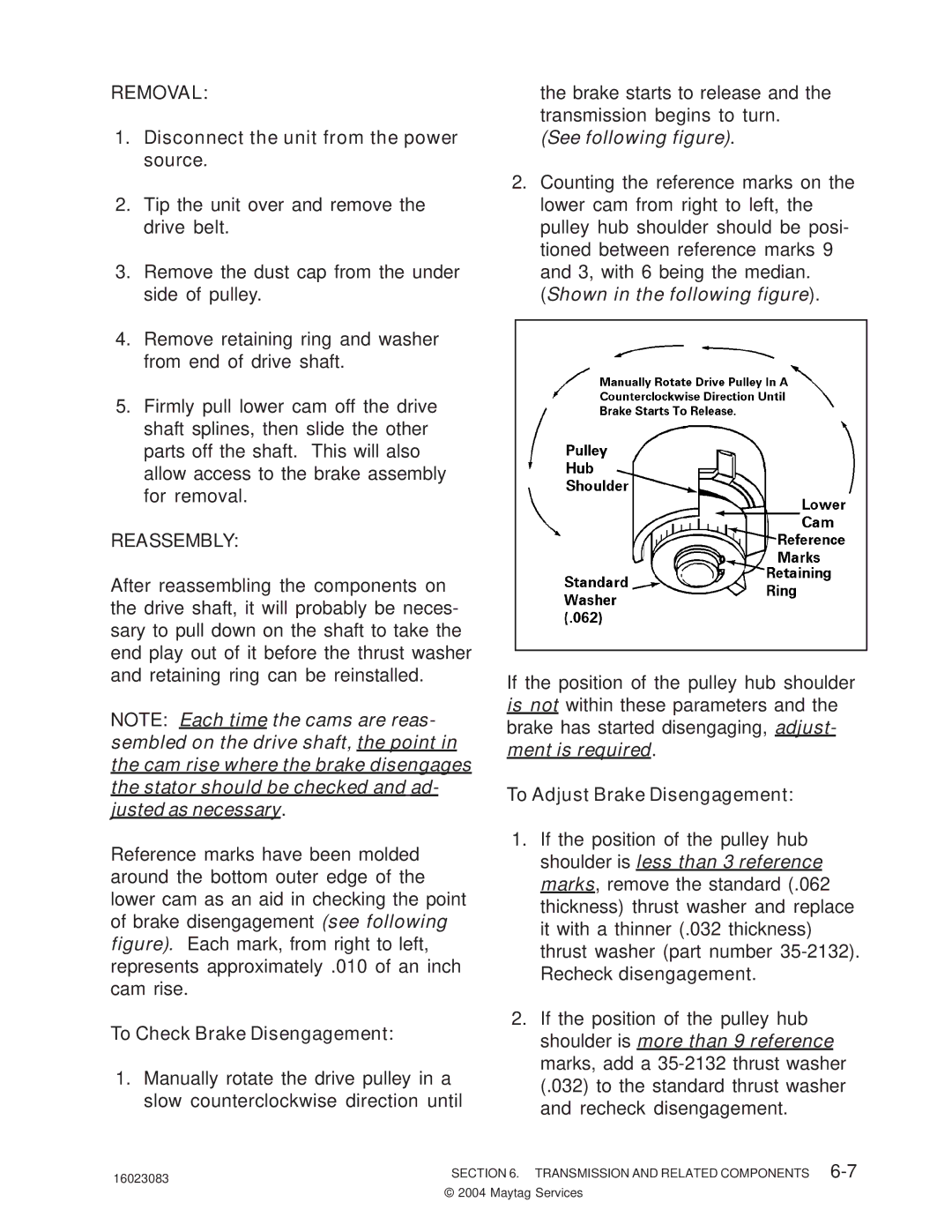

Reference marks have been molded around the bottom outer edge of the lower cam as an aid in checking the point of brake disengagement (see following figure). Each mark, from right to left, represents approximately .010 of an inch cam rise.

To Check Brake Disengagement:

1.Manually rotate the drive pulley in a slow counterclockwise direction until

the brake starts to release and the transmission begins to turn.

(See following figure).

2.Counting the reference marks on the lower cam from right to left, the pulley hub shoulder should be posi- tioned between reference marks 9 and 3, with 6 being the median. (Shown in the following figure).

If the position of the pulley hub shoulder is not within these parameters and the brake has started disengaging, adjust- ment is required.

To Adjust Brake Disengagement:

1.If the position of the pulley hub shoulder is less than 3 reference marks, remove the standard (.062 thickness) thrust washer and replace it with a thinner (.032 thickness) thrust washer (part number

2.If the position of the pulley hub shoulder is more than 9 reference marks, add a

16023083 | SECTION 6. TRANSMISSION AND RELATED COMPONENTS |

| © 2004 Maytag Services |