2. Screw in leveling legs

diamond ![]() marking

marking ![]()

Examine leveling legs, find diamond marking. Screw legs into leg holes by hand, use a wrench to finish turning legs until diamond marking is no longer visible.

Now stand the dryer on its feet. Slide the dryer until it is close to its final location. Leave enough room to connect the exhaust vent.

For mobile home use

Gas dryers must be securely fastened to the floor.

Mobile home installations require a Mobile Home Installation

GAS DRYER POWER

HOOKUP

Gas Supply Requirements

![]() WARNING

WARNING

Gas type

Natural gas:

This dryer is equipped for use with Natural Gas. It is design- certified by CSA International for LP (propane or butane) gases with appropriate conversion.

■■ Your dryer must have the correct burner for the type of gas in your home. Burner information is located on the rating plate in the door well of your dryer. If this information does not agree with the type of gas available, please reference the “Assistance or Service” section of the “Dryer User Instructions.”

LP gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the dryer from the gas specified on the model/serial rating plate for use with a different gas without consulting the serving gas supplier.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

Gas supply line

■■ 1/2" NPT pipe is recommended.

■■ 3/8" approved tubing is acceptable for lengths under 20 ft. (6.1 m) if local codes and gas supplier permit.

■■ Must include 1/8" NPT minimum plugged tapping accessible for test gauge connection, immediately upstream of the gas connection to the dryer (see illustration).

■■ Must include a shutoff valve:

In the U.S.A.:

An individual manual shutoff valve must be installed within six (6) feet (1.8 m) of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1.

In Canada:

An individual manual shutoff valve must be installed in accordance with the B149.1, Natural Gas and Propane Installation Code. It is recommended that an individual manual shutoff valve be installed within six (6) feet (1.8 m) of the dryer.

The shut off valve location should be easy to reach for opening and closing.

Explosion Hazard

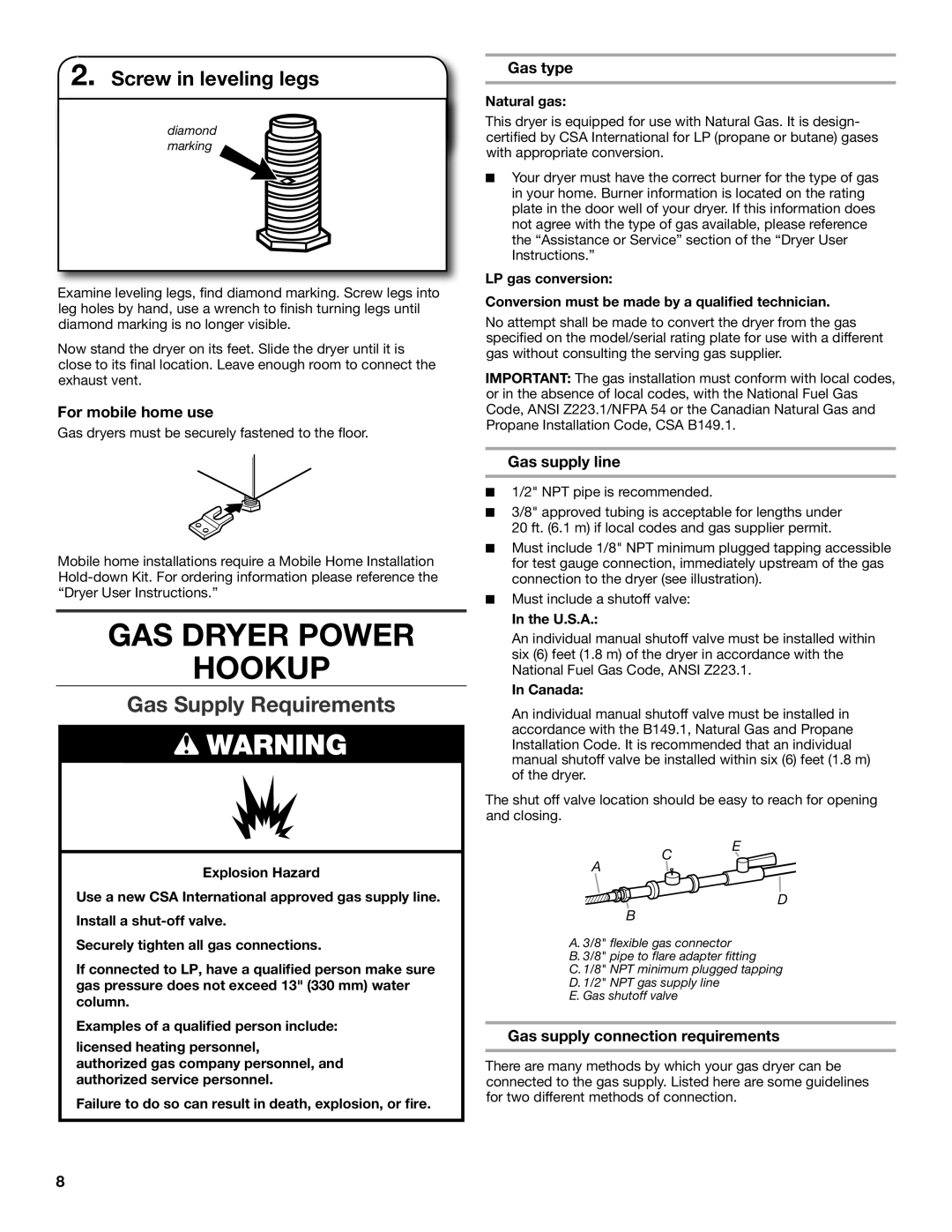

A

C E

Use a new CSA International approved gas supply line. Install a

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure gas pressure does not exceed 13" (330 mm) water column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and authorized service personnel.

Failure to do so can result in death, explosion, or fire.

D

B

A. 3/8" flexible gas connector

B. 3/8" pipe to flare adapter fitting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shutoff valve

Gas supply connection requirements

There are many methods by which your gas dryer can be connected to the gas supply. Listed here are some guidelines for two different methods of connection.

8