5 Maintenance and Servicing

Due to the high quality materials and components used for this accessory maintenance is kept to a minimum. The hardened and polished guide bars (317/333) and the four rollers should be oiled regularly with gun oil to keep from rust. All bearings are greased for life.

The four rollers are factory set. However, if a roller carriage extrusion (316/332) or traversing saddle (310) is replaced, the rollers may need adjustment.

Loosen bolts "D" of the lower rollers. Adjust by setting the eccentric bush (326) of each roller until carriage runs smooth with as little play as possible.

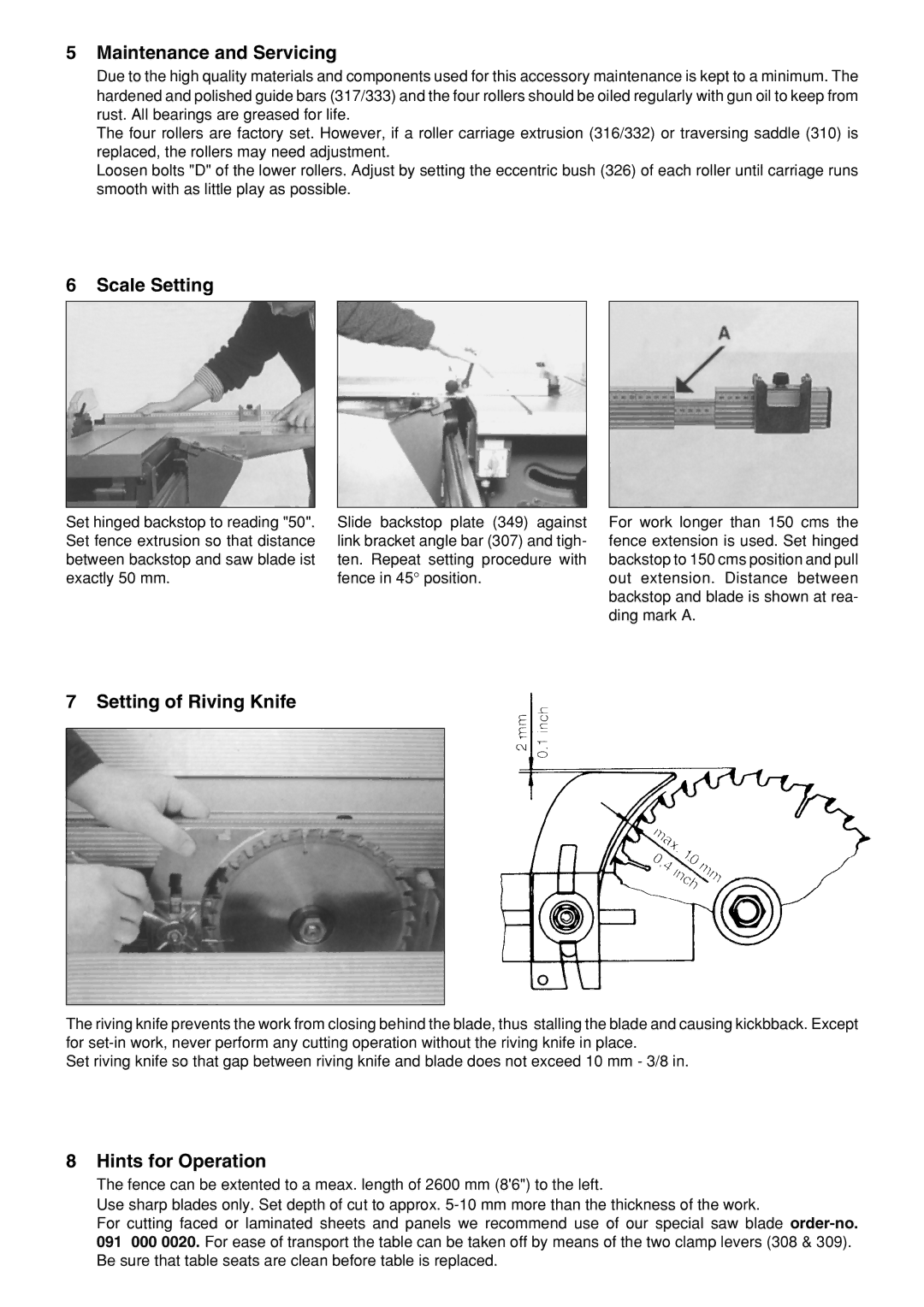

6 Scale Setting

Set hinged backstop to reading "50". Set fence extrusion so that distance between backstop and saw blade ist exactly 50 mm.

Slide backstop plate (349) against link bracket angle bar (307) and tigh- ten. Repeat setting procedure with fence in 45° position.

For work longer than 150 cms the fence extension is used. Set hinged backstop to 150 cms position and pull out extension. Distance between backstop and blade is shown at rea- ding mark A.

7 Setting of Riving Knife

The riving knife prevents the work from closing behind the blade, thus stalling the blade and causing kickbback. Except for

Set riving knife so that gap between riving knife and blade does not exceed 10 mm - 3/8 in.

8 Hints for Operation

The fence can be extented to a meax. length of 2600 mm (8'6") to the left.

Use sharp blades only. Set depth of cut to approx.

For cutting faced or laminated sheets and panels we recommend use of our special saw blade

091000 0020. For ease of transport the table can be taken off by means of the two clamp levers (308 & 309). Be sure that table seats are clean before table is replaced.