ROUTER BITS

PRECISION AT THE EXTREME.

Precision cuts require precision tooling. If you want the best from your router do not sacrifice on the cutters. Metabo cutters are of a high standard, manufactured by tooling specialists with many years of experience and

by machines that can produce repeat profiles time and time again. Metabo router bits will give you what you need to perform clean, smooth, consistent cuts in safety.

Structure and function of Metabo routers

Cutting tools

The specification of the cutting tool material by the manufacturer

is decisive for the quality of the cutter. Only top quality alloys of faultless structural consistence can meet the demands for a long service life. Selection and control of the cutting tools have high priority at Metabo.

HSS-tools

Ideal for use on soft woods, with reasonable life when processing

HM-routers

Ideal for use on hardwoods, kitchen worktops, and laminate boards. Various

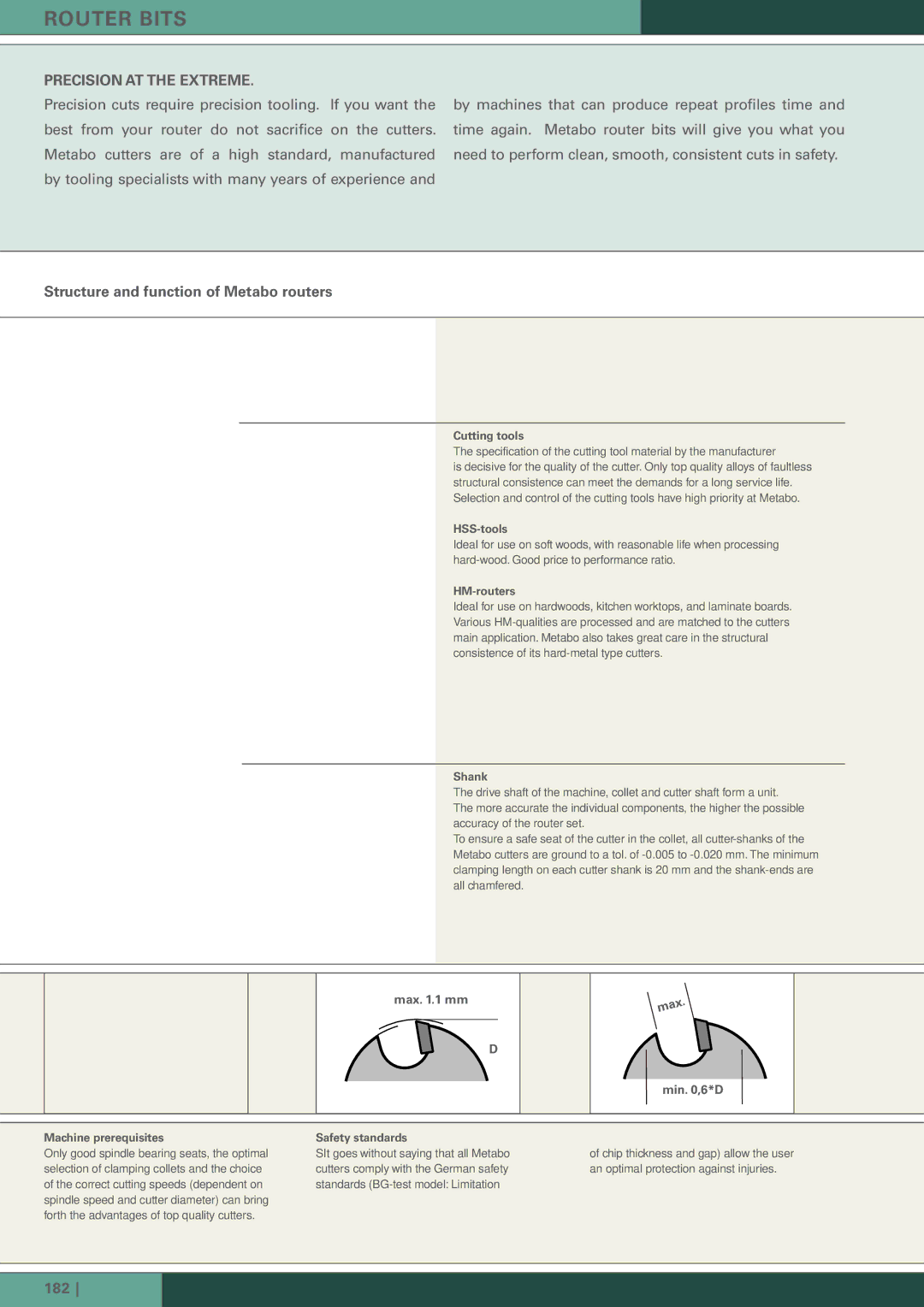

Shank

The drive shaft of the machine, collet and cutter shaft form a unit.

The more accurate the individual components, the higher the possible accuracy of the router set.

To ensure a safe seat of the cutter in the collet, all

max. 1.1 mm

➞ ![]() ➞

➞![]()

➞ D

| .➞ |

|

➞ | max |

|

|

| |

➞ min. 0,6*D | ➞ | |

Machine prerequisites | Safety standards |

|

Only good spindle bearing seats, the optimal | SIt goes without saying that all Metabo | of chip thickness and gap) allow the user |

selection of clamping collets and the choice | cutters comply with the German safety | an optimal protection against injuries. |

of the correct cutting speeds (dependent on | standards |

|

spindle speed and cutter diameter) can bring |

|

|

forth the advantages of top quality cutters. |

|

|

|

|

|

182