160, 185 specifications

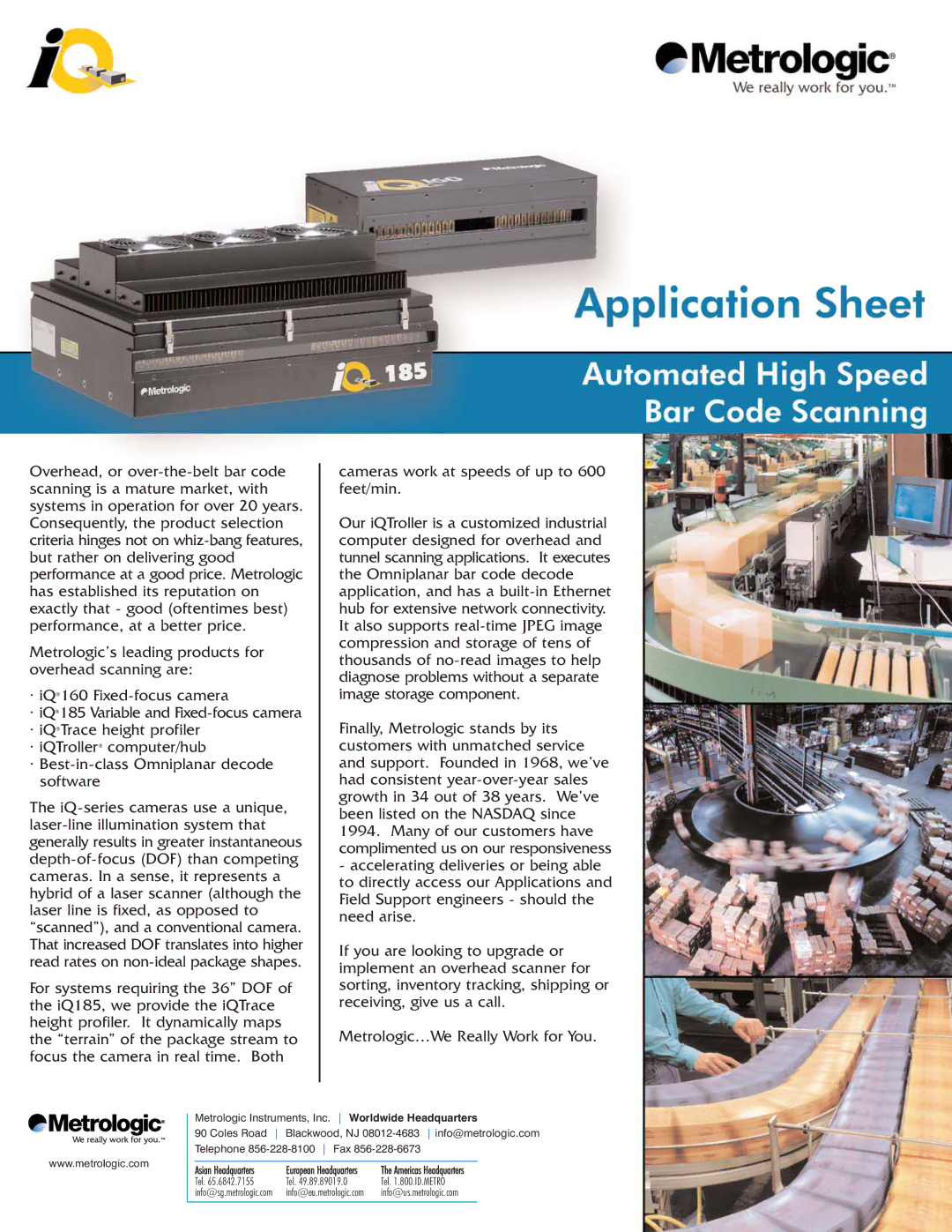

Metrologic Instruments has established itself as a leader in the design and manufacturing of advanced measurement and data capture solutions. Among its notable products are the Metrologic Instruments 160 and 185 models, which are particularly renowned for their precision and versatility in various applications.The Metrologic Instruments 160 model is designed for efficiency and ease of use. It boasts a robust construction that allows it to withstand harsh operational environments, making it ideal for industrial applications. One of its standout features is its high-speed data capture capability, which enables users to quickly and accurately record measurements without compromising on quality. The 160 model incorporates advanced laser technology, ensuring that measurements are not only precise but also quick, minimizing downtime during operation.

On the other hand, the Metrologic Instruments 185 model builds on the foundation laid by the 160, adding enhanced functionalities that cater to more complex measurement requirements. The 185 model features a larger measurement range and incorporates wireless connectivity options, allowing for seamless data transfer to connected devices. This feature enhances productivity by enabling real-time monitoring and analysis of collected data.

Both models utilize a user-friendly interface that simplifies navigation through menus and settings. Additionally, they are equipped with cutting-edge software that offers advanced data analysis tools, making it easy for users to interpret results and generate reports. This software compatibility not only streamlines workflow but also increases the overall efficiency of data handling processes.

Another characteristic worth mentioning is the adaptability of these models. They can be tailored to meet specific industry needs, making them suitable for sectors such as manufacturing, logistics, and quality control. Their versatility is further enhanced by the availability of customizable attachments and accessories, allowing users to adapt the instruments for various measurement tasks.

Furthermore, Metrologic Instruments prides itself on offering robust customer support and comprehensive training resources, ensuring that users can maximize the benefits of their measurement tools. With the combination of precision engineering, innovative technologies, and user-centered design, the Metrologic Instruments 160 and 185 models stand out as reliable solutions for modern measurement challenges. These instruments exemplify the brand's commitment to advancing measurement technology while meeting the diverse needs of its customers.