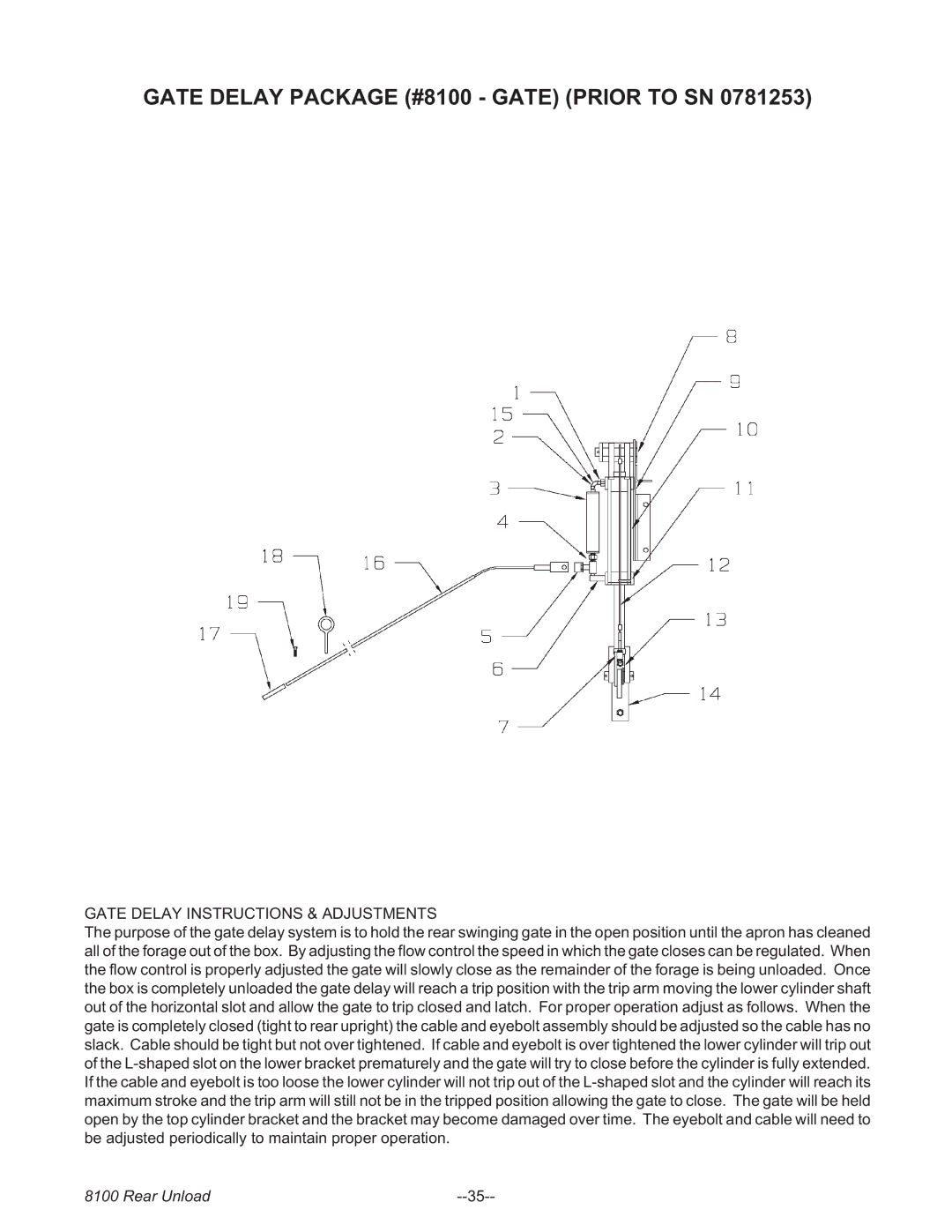

GATE DELAY PACKAGE (#8100 - GATE) (PRIOR TO SN 0781253)

GATE DELAY INSTRUCTIONS & ADJUSTMENTS

The purpose of the gate delay system is to hold the rear swinging gate in the open position until the apron has cleaned all of the forage out of the box. By adjusting the flow control the speed in which the gate closes can be regulated. When the flow control is properly adjusted the gate will slowly close as the remainder of the forage is being unloaded. Once the box is completely unloaded the gate delay will reach a trip position with the trip arm moving the lower cylinder shaft out of the horizontal slot and allow the gate to trip closed and latch. For proper operation adjust as follows. When the gate is completely closed (tight to rear upright) the cable and eyebolt assembly should be adjusted so the cable has no slack. Cable should be tight but not over tightened. If cable and eyebolt is over tightened the lower cylinder will trip out of the

8100 Rear Unload |