250A specifications

MGE UPS Systems has garnered a reputation for delivering high-quality power protection solutions, and the 250A model stands out as an excellent choice for businesses seeking reliable uninterruptible power supply (UPS) systems. This particular model is designed to handle critical loads while ensuring continuous power availability and safeguarding equipment against power disturbances.One of the main features of the MGE UPS Systems 250A is its robust power capacity. It can efficiently supply power to critical devices, making it suitable for a range of applications including data centers, telecommunication networks, and industrial environments. The 250A offers a highly scalable solution, allowing businesses to expand their power needs as they grow.

In terms of technology, the MGE UPS Systems 250A utilizes advanced double-conversion technology, which converts incoming AC power to DC and then back to AC. This process ensures that the connected equipment receives a consistent and clean sine wave output, free from fluctuations and disturbances. The UPS is equipped with high-efficiency operation modes, including Eco-mode, which help reduce energy consumption and operational costs while maintaining optimal performance.

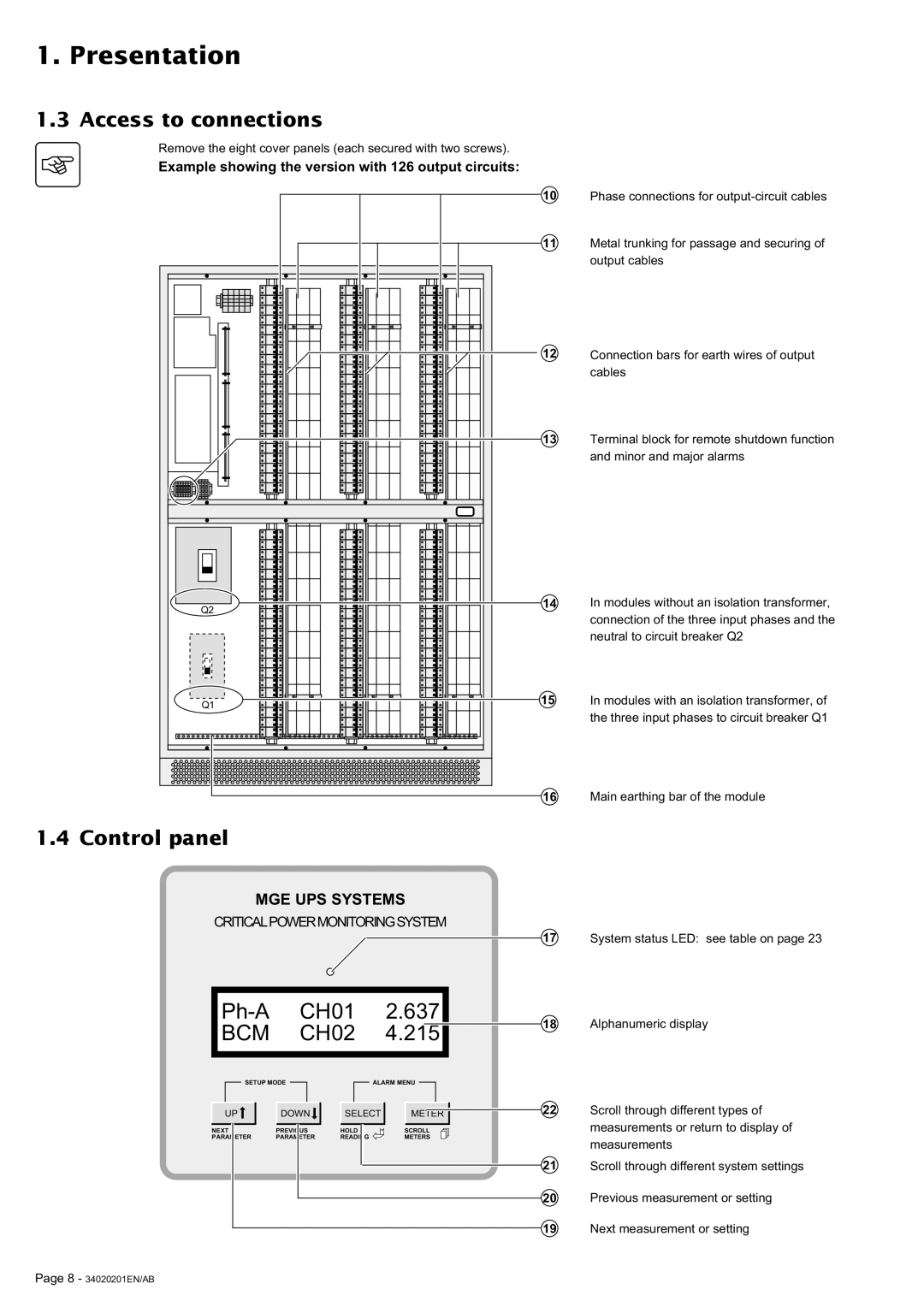

Another notable characteristic of the 250A is its versatility in connectivity and integration. It features a comprehensive range of communication ports, enabling seamless integration with existing infrastructures. The UPS can be monitored and managed remotely, allowing for real-time insights into the power status and performance metrics. This level of monitoring is crucial for ensuring optimal operation and for preemptively addressing potential issues.

Moreover, MGE UPS Systems has placed a strong emphasis on user-friendly design in the 250A model. The intuitive interface and clear display make it easy for operators to navigate through settings and configurations. Additionally, the modular design of the UPS allows for easy maintenance and upgrades, minimizing downtime and optimizing service efficiency.

To enhance its reliability, the MGE UPS Systems 250A comes with multiple safety features, including overload protection, short circuit protection, and temperature monitoring. These safeguards ensure that the system operates within safe parameters, reducing the risk of damage to both the UPS and connected equipment.

In summary, the MGE UPS Systems 250A is a powerful and versatile solution for businesses requiring reliable power protection. With its advanced technology, energy-efficient design, and user-friendly features, it meets the demands of modern power requirements while ensuring seamless operation and equipment safety.