D.Conveyor Installation

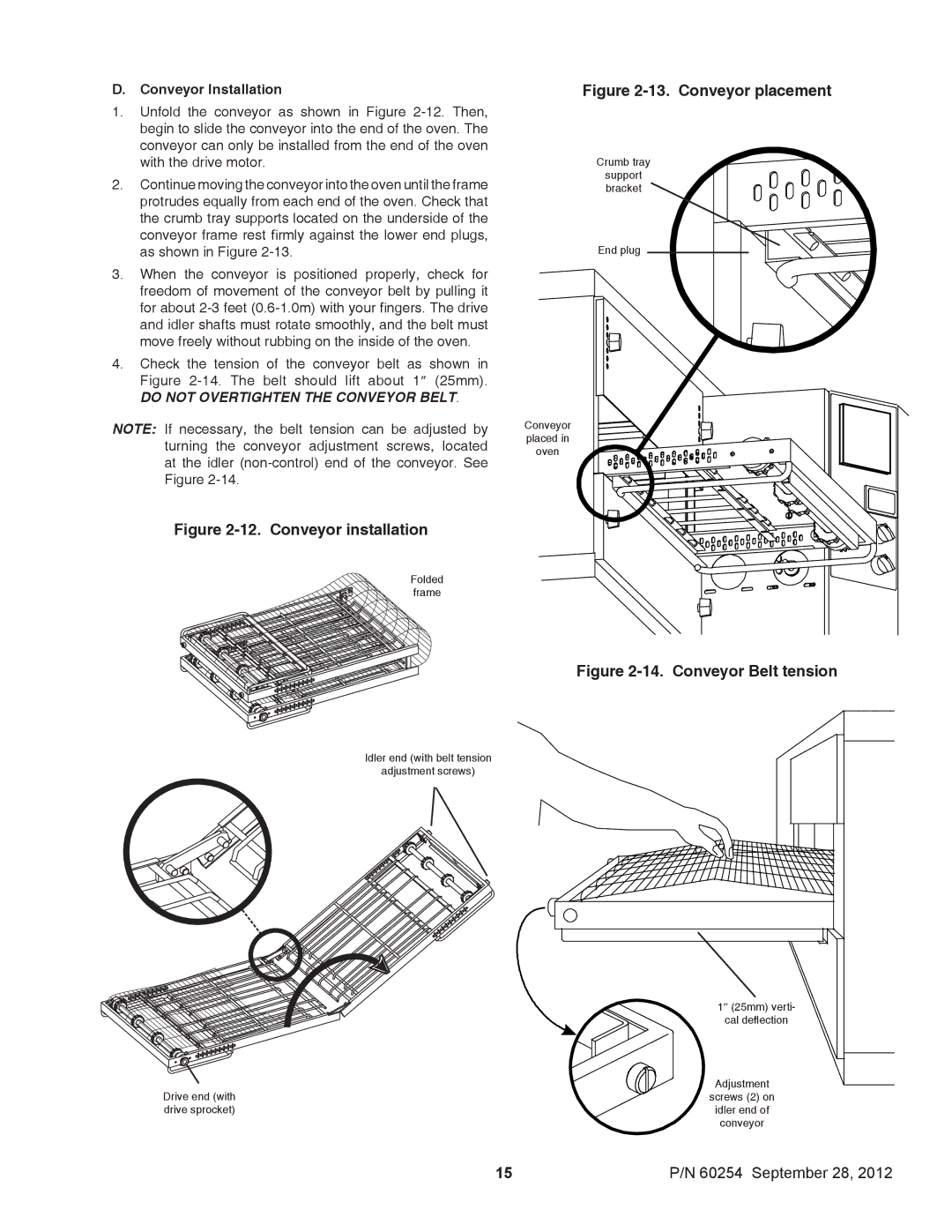

1.Unfold the conveyor as shown in Figure

2.Continue moving the conveyor into the oven until the frame protrudes equally from each end of the oven. Check that the crumb tray supports located on the underside of the conveyor frame rest firmly against the lower end plugs, as shown in Figure

3.When the conveyor is positioned properly, check for freedom of movement of the conveyor belt by pulling it for about

4.Check the tension of the conveyor belt as shown in Figure

DO NOT OVERTIGHTEN THE CONVEYOR BELT.

NOTE: If necessary, the belt tension can be adjusted by turning the conveyor adjustment screws, located at the idler

Figure 2-12. Conveyor installation

Folded

frame

Figure 2-13. Conveyor placement

Crumb tray

support bracket

End plug

Conveyor placed in oven

Figure 2-14. Conveyor Belt tension

Idler end (with belt tension

adjustment screws)

Drive end (with drive sprocket)

1″ (25mm) verti-

cal deflection

Adjustment

screws (2) on

idler end of

conveyor

15 | P/N 60254 September 28, 2012 |