.A complete Parts List is available at www.MillerWelds.com

SECTION 6 − MAINTENANCE & TROUBLESHOOTING

6-1. Routine Maintenance

![]() ! Disconnect power before maintaining.

! Disconnect power before maintaining.

3 Months

Replace unreadable labels.

Repair or replace cracked weld cable.

Clean and tighten weld terminals.

6 Months

Blow out or vacuum inside.

During heavy service, clean monthly.

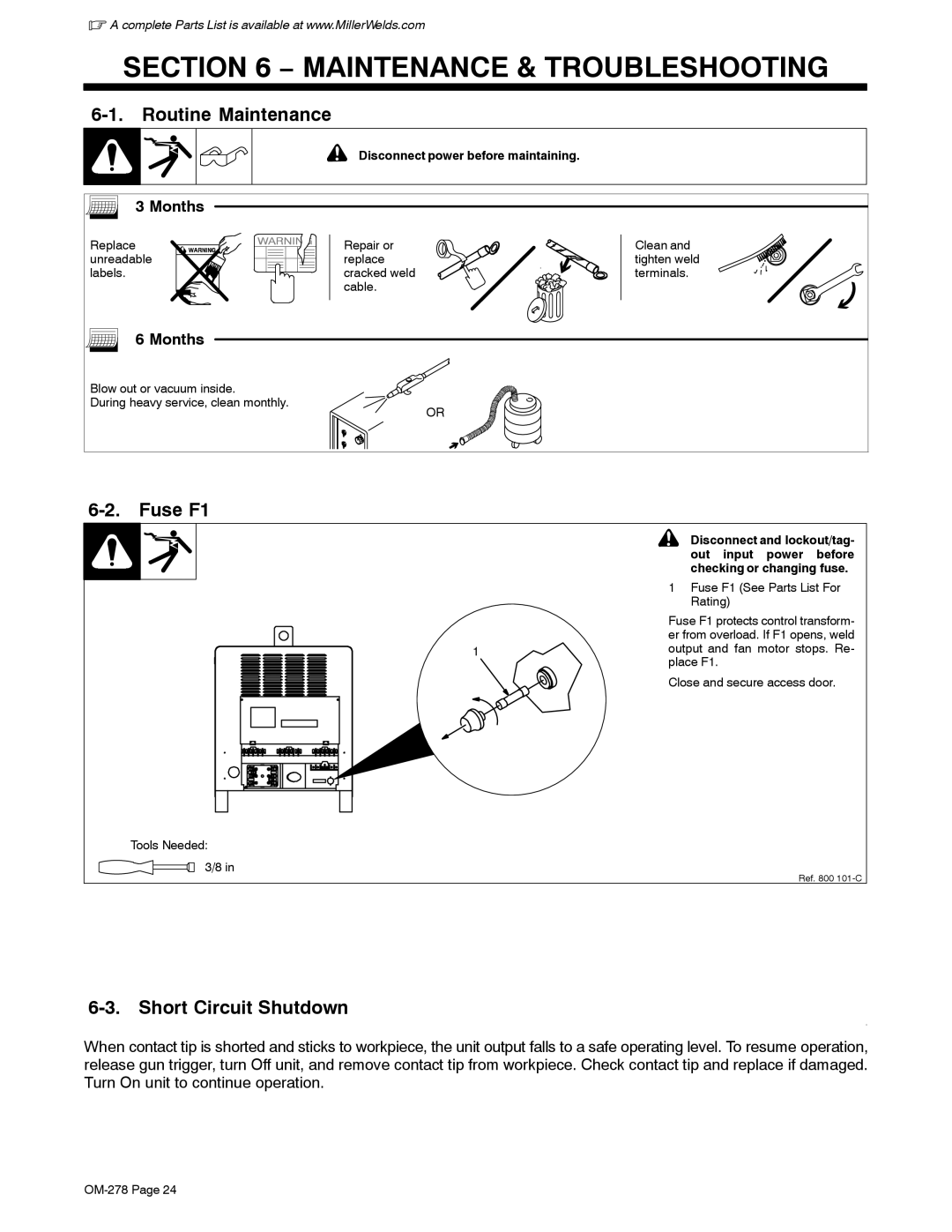

6-2. Fuse F1

Tools Needed:

3/8 in

OR

![]() ! Disconnect and lockout/tag- out input power before checking or changing fuse.

! Disconnect and lockout/tag- out input power before checking or changing fuse.

1 Fuse F1 (See Parts List For Rating)

Fuse F1 protects control transform- er from overload. If F1 opens, weld

1output and fan motor stops. Re- place F1.

Close and secure access door.

Ref. 800

6-3. Short Circuit Shutdown

When contact tip is shorted and sticks to workpiece, the unit output falls to a safe operating level. To resume operation, release gun trigger, turn Off unit, and remove contact tip from workpiece. Check contact tip and replace if damaged. Turn On unit to continue operation.