SECTION 4 − MAINTENANCE AND TROUBLESHOOTING

4-1. Routine Maintenance

Y Disconnect power before maintaining.

n = Check | Z = Change | ~ = Clean | l = Replace | Reference |

* To be done by Factory Authorized Service Agent |

|

| ||

Every | l Unreadable Labels | ~ Weld Terminals | nl Weld Cables | l Cracked Parts |

3 | ||||

Months |

|

|

|

|

| n Gun Cable | n Gas Hose And Fittings |

|

|

Every |

|

|

|

|

6 |

|

|

|

|

Months | Or |

|

|

|

| ~ Inside Of Unit | ~ Drive Rolls |

|

|

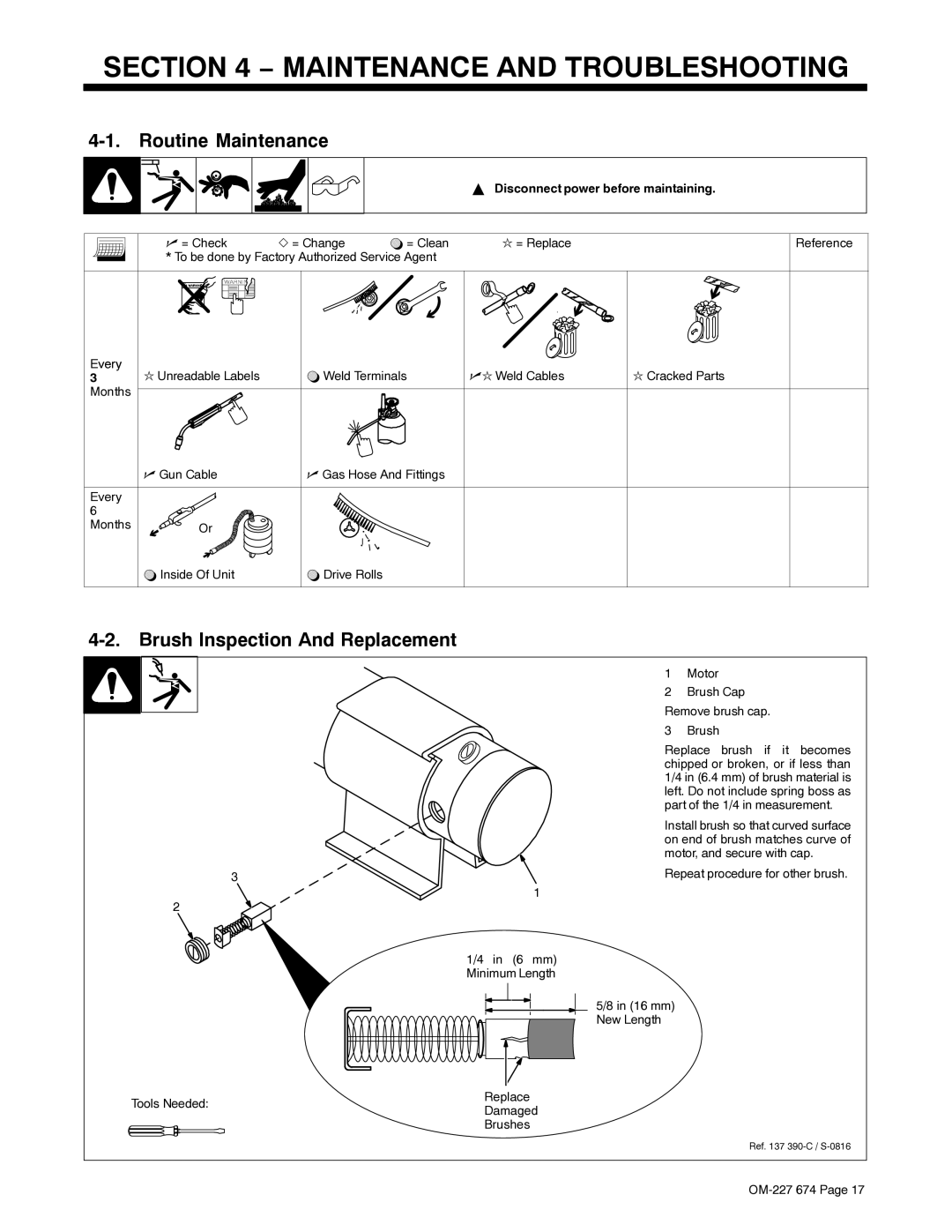

4-2. Brush Inspection And Replacement

1 Motor

2 Brush Cap Remove brush cap.

3 Brush

Replace brush if it becomes chipped or broken, or if less than 1/4 in (6.4 mm) of brush material is left. Do not include spring boss as part of the 1/4 in measurement.

Install brush so that curved surface on end of brush matches curve of motor, and secure with cap.

3 | Repeat procedure for other brush. |

1

2

1/4 in (6 mm) Minimum Length

5/8 in (16 mm) New Length

Tools Needed: | Replace | |

Damaged | ||

| ||

| Brushes |

Ref. 137