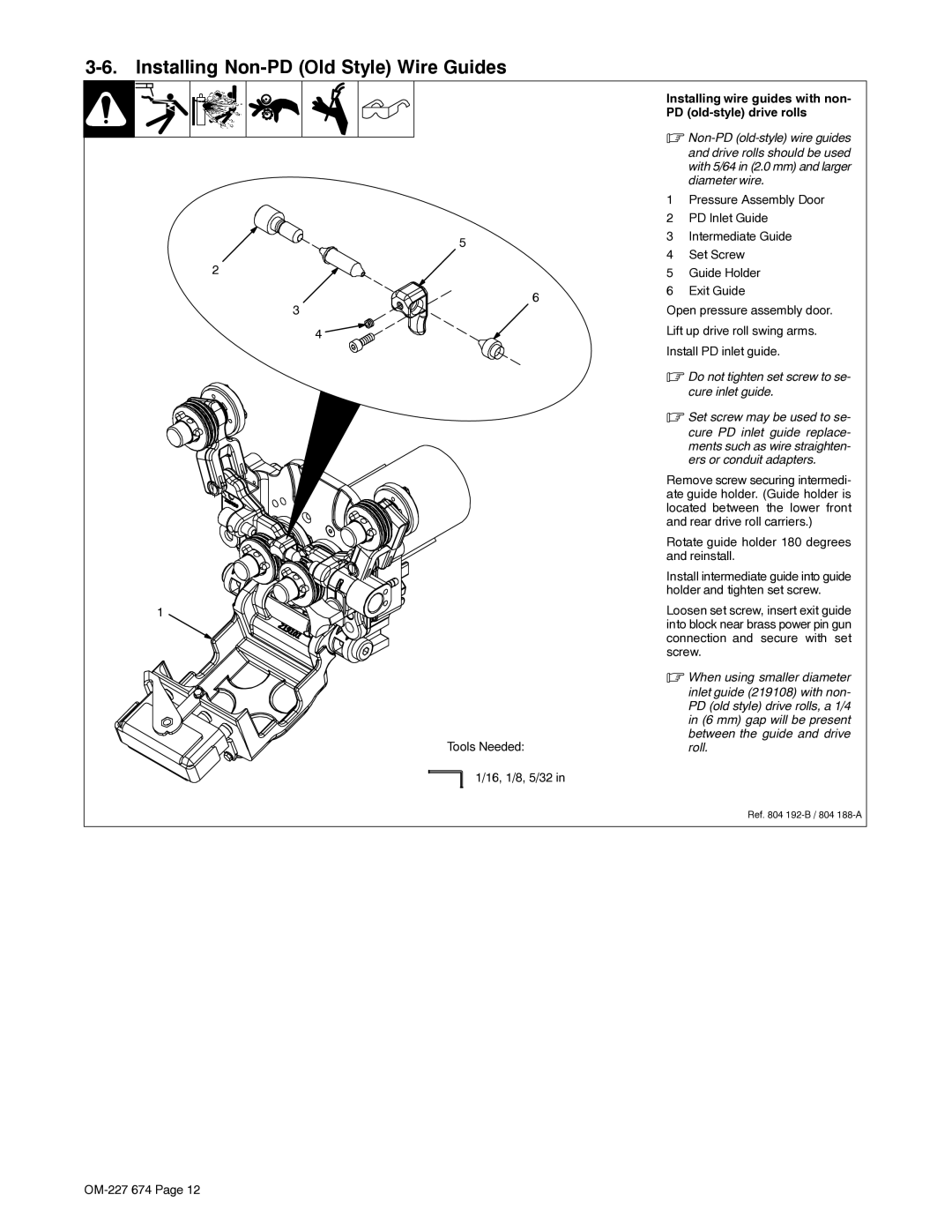

3-6. Installing Non-PD (Old Style) Wire Guides

5

2

6

3

4 ![]()

![]()

1

Tools Needed:

1/16, 1/8, 5/32 in

Installing wire guides with non- PD (old-style) drive rolls

.

1Pressure Assembly Door

2PD Inlet Guide

3Intermediate Guide

4Set Screw

5Guide Holder

6Exit Guide

Open pressure assembly door. Lift up drive roll swing arms. Install PD inlet guide.

.Do not tighten set screw to se- cure inlet guide.

.Set screw may be used to se-

cure PD inlet guide replace- ments such as wire straighten- ers or conduit adapters.

Remove screw securing intermedi- ate guide holder. (Guide holder is located between the lower front and rear drive roll carriers.)

Rotate guide holder 180 degrees and reinstall.

Install intermediate guide into guide holder and tighten set screw.

Loosen set screw, insert exit guide into block near brass power pin gun connection and secure with set screw.

.When using smaller diameter inlet guide (219108) with non- PD (old style) drive rolls, a 1/4 in (6 mm) gap will be present between the guide and drive roll.

Ref. 804