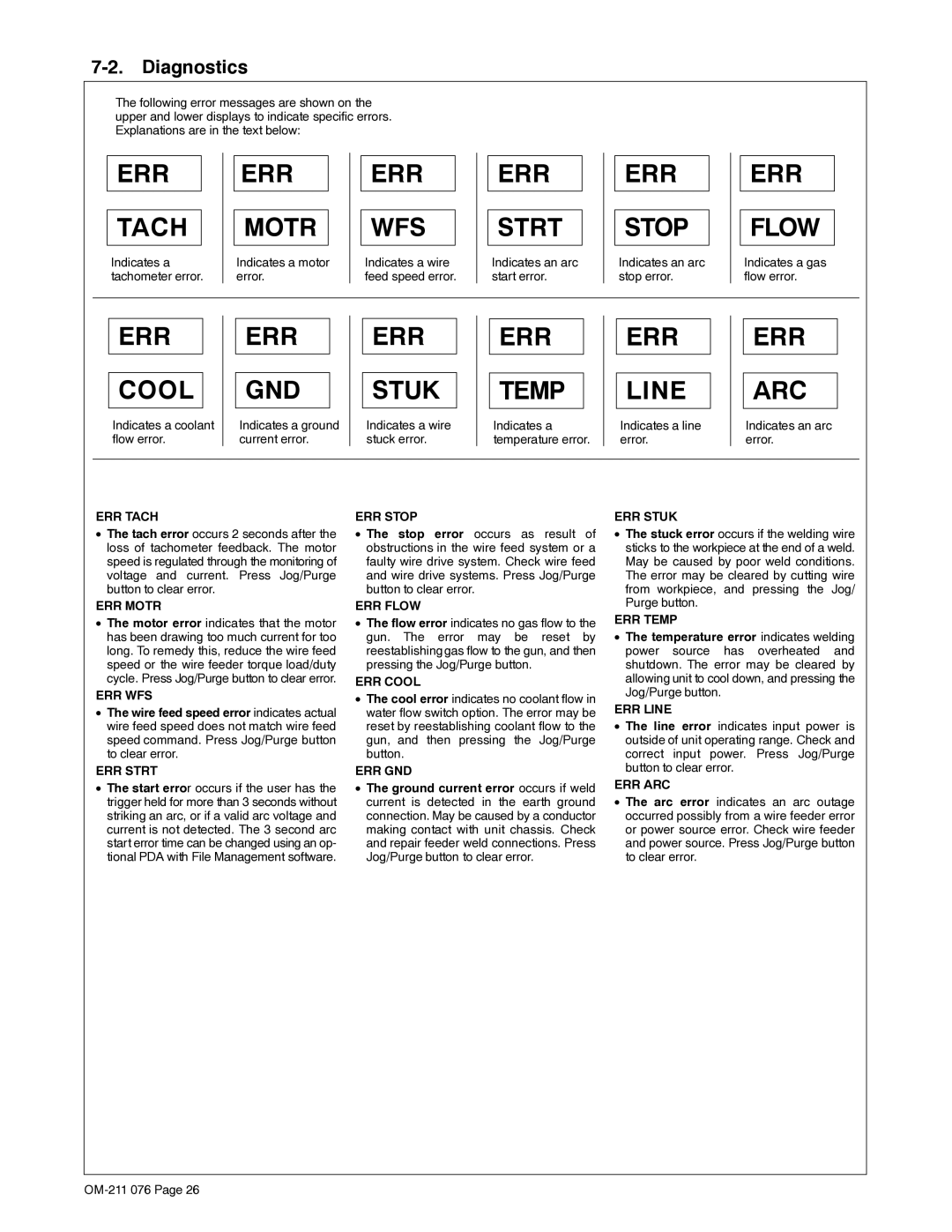

7-2. Diagnostics

The following error messages are shown on the upper and lower displays to indicate specific errors. Explanations are in the text below:

ERR

TACH

Indicates a tachometer error.

ERR

MOTR

Indicates a motor error.

ERR

WFS

Indicates a wire feed speed error.

ERR

STRT

Indicates an arc start error.

ERR

STOP

Indicates an arc stop error.

ERR

FLOW

Indicates a gas flow error.

ERR

COOL

Indicates a coolant flow error.

ERR

GND

Indicates a ground current error.

ERR

STUK

Indicates a wire stuck error.

ERR

TEMP

Indicates a temperature error.

ERR

LINE

Indicates a line error.

ERR

ARC

Indicates an arc error.

ERR TACH

•The tach error occurs 2 seconds after the loss of tachometer feedback. The motor speed is regulated through the monitoring of voltage and current. Press Jog/Purge button to clear error.

ERR MOTR

•The motor error indicates that the motor has been drawing too much current for too long. To remedy this, reduce the wire feed speed or the wire feeder torque load/duty cycle. Press Jog/Purge button to clear error.

ERR WFS

•The wire feed speed error indicates actual wire feed speed does not match wire feed speed command. Press Jog/Purge button to clear error.

ERR STRT

•The start error occurs if the user has the trigger held for more than 3 seconds without striking an arc, or if a valid arc voltage and current is not detected. The 3 second arc start error time can be changed using an op- tional PDA with File Management software.

ERR STOP

•The stop error occurs as result of obstructions in the wire feed system or a faulty wire drive system. Check wire feed and wire drive systems. Press Jog/Purge button to clear error.

ERR FLOW

•The flow error indicates no gas flow to the gun. The error may be reset by reestablishing gas flow to the gun, and then pressing the Jog/Purge button.

ERR COOL

•The cool error indicates no coolant flow in water flow switch option. The error may be reset by reestablishing coolant flow to the gun, and then pressing the Jog/Purge button.

ERR GND

•The ground current error occurs if weld current is detected in the earth ground connection. May be caused by a conductor making contact with unit chassis. Check and repair feeder weld connections. Press Jog/Purge button to clear error.

ERR STUK

•The stuck error occurs if the welding wire sticks to the workpiece at the end of a weld. May be caused by poor weld conditions. The error may be cleared by cutting wire from workpiece, and pressing the Jog/ Purge button.

ERR TEMP

•The temperature error indicates welding power source has overheated and shutdown. The error may be cleared by allowing unit to cool down, and pressing the Jog/Purge button.

ERR LINE

•The line error indicates input power is outside of unit operating range. Check and correct input power. Press Jog/Purge button to clear error.

ERR ARC

•The arc error indicates an arc outage occurred possibly from a wire feeder error or power source error. Check wire feeder and power source. Press Jog/Purge button to clear error.