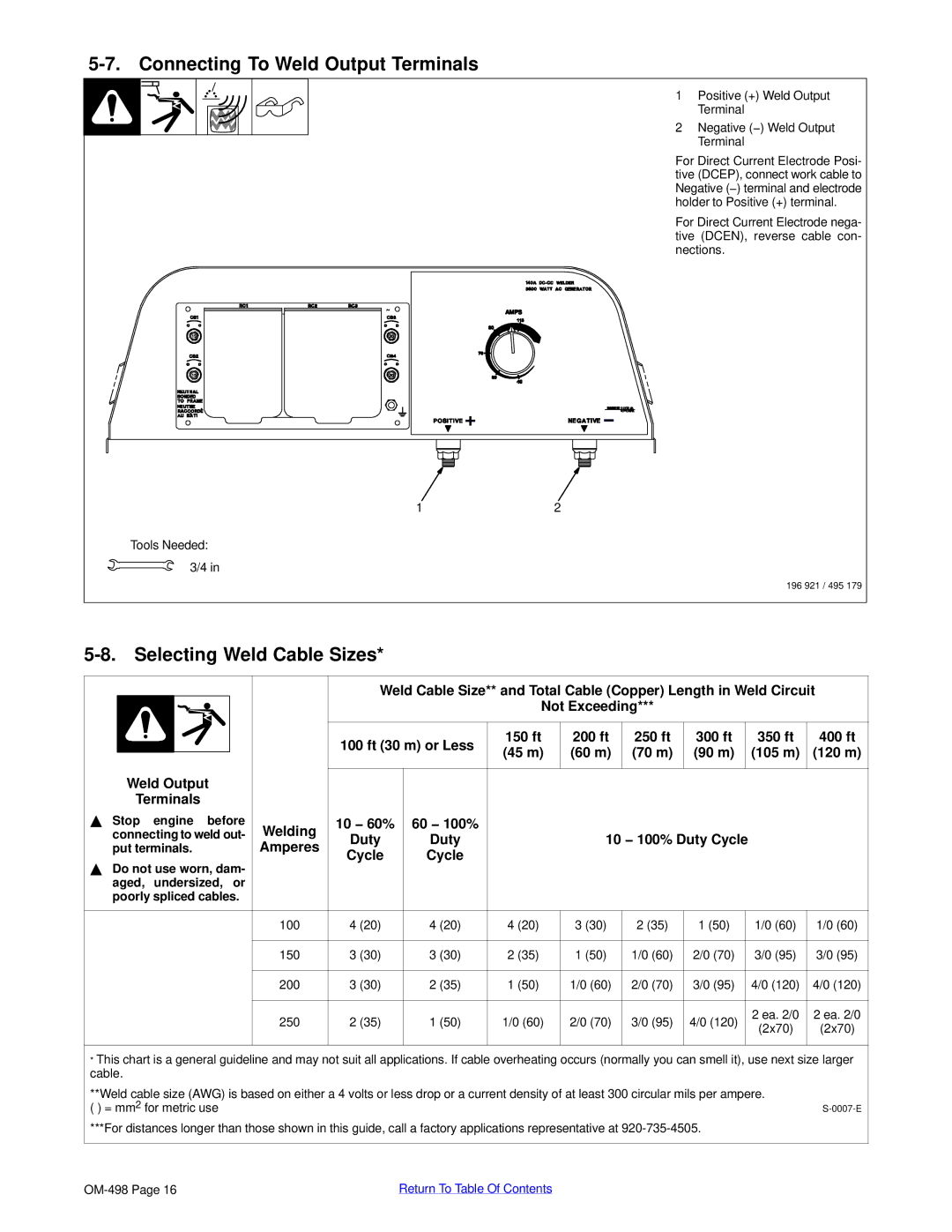

5-7. Connecting To Weld Output Terminals

1 Positive (+) Weld Output

Terminal

2 Negative (−) Weld Output

Terminal

For Direct Current Electrode Posi- tive (DCEP), connect work cable to Negative (−) terminal and electrode holder to Positive (+) terminal.

For Direct Current Electrode nega- tive (DCEN), reverse cable con- nections.

12

Tools Needed:

3/4 in

196 921 / 495 179

5-8. Selecting Weld Cable Sizes*

|

|

|

|

| Weld Cable Size** and Total Cable (Copper) Length in Weld Circuit | |||||||

|

|

|

|

|

|

| Not Exceeding*** |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 100 ft (30 m) or Less | 150 ft | 200 ft | 250 ft | 300 ft | 350 ft | 400 ft | |

|

|

|

|

| (45 m) | (60 m) | (70 m) | (90 m) | (105 m) | (120 m) | ||

| Weld Output |

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |||

| Terminals |

|

|

|

|

|

|

|

|

| ||

Y Stop engine before | Welding | 10 − 60% | 60 − 100% |

|

|

|

|

|

| |||

connecting to weld out- | Duty | Duty |

| 10 − 100% Duty Cycle |

|

| ||||||

put terminals. | Amperes |

|

|

| ||||||||

Cycle | Cycle |

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

| ||

YDo not use worn, dam- aged, undersized, or poorly spliced cables.

100 | 4 (20) | 4 (20) | 4 (20) | 3 (30) | 2 (35) | 1 (50) | 1/0 (60) | 1/0 (60) | ||

|

|

|

|

|

|

|

|

|

| |

150 | 3 (30) | 3 (30) | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 3/0 (95) | ||

|

|

|

|

|

|

|

|

|

| |

200 | 3 (30) | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 (120) | 4/0 (120) | ||

|

|

|

|

|

|

|

|

|

| |

250 | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 (120) | 2 ea. 2/0 | 2 ea. 2/0 | ||

(2x70) | (2x70) | |||||||||

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |

*This chart is a general guideline and may not suit all applications. If cable overheating occurs (normally you can smell it), use next size larger cable.

**Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. ( ) = mm2 for metric use

***For distances longer than those shown in this guide, call a factory applications representative at

Return To Table Of Contents |