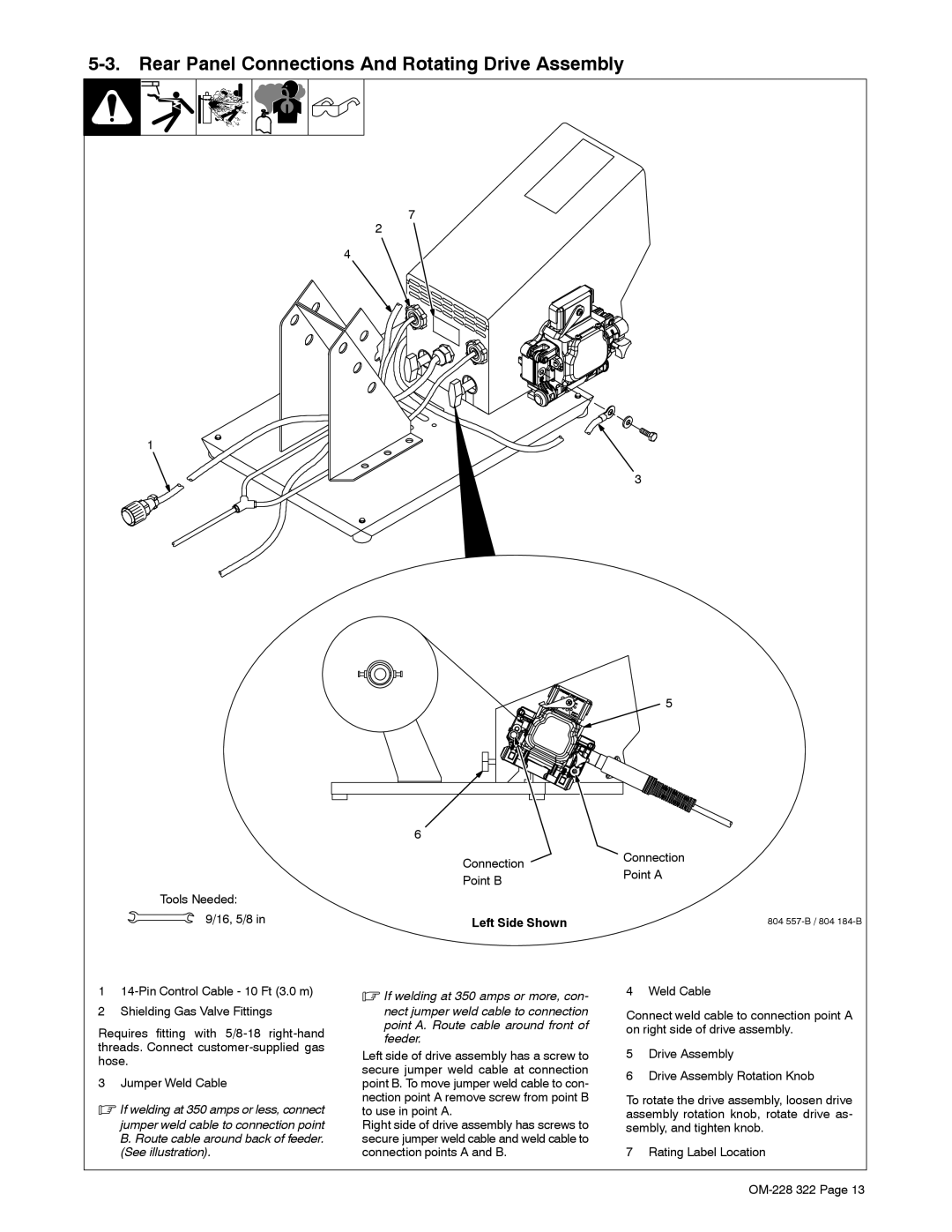

5-3. Rear Panel Connections And Rotating Drive Assembly

1

Tools Needed: 9/16, 5/8 in

7

2

4

3

5

6

Connection | Connection | |

Point A | ||

Point B | ||

| ||

Left Side Shown | 804 |

1

2Shielding Gas Valve Fittings

Requires fitting with

3 Jumper Weld Cable

.If welding at 350 amps or less, connect

jumper weld cable to connection point B. Route cable around back of feeder. (See illustration).

.If welding at 350 amps or more, con-

nect jumper weld cable to connection point A. Route cable around front of feeder.

Left side of drive assembly has a screw to secure jumper weld cable at connection point B. To move jumper weld cable to con- nection point A remove screw from point B to use in point A.

Right side of drive assembly has screws to secure jumper weld cable and weld cable to connection points A and B.

4 Weld Cable

Connect weld cable to connection point A on right side of drive assembly.

5Drive Assembly

6Drive Assembly Rotation Knob

To rotate the drive assembly, loosen drive assembly rotation knob, rotate drive as- sembly, and tighten knob.

7 Rating Label Location