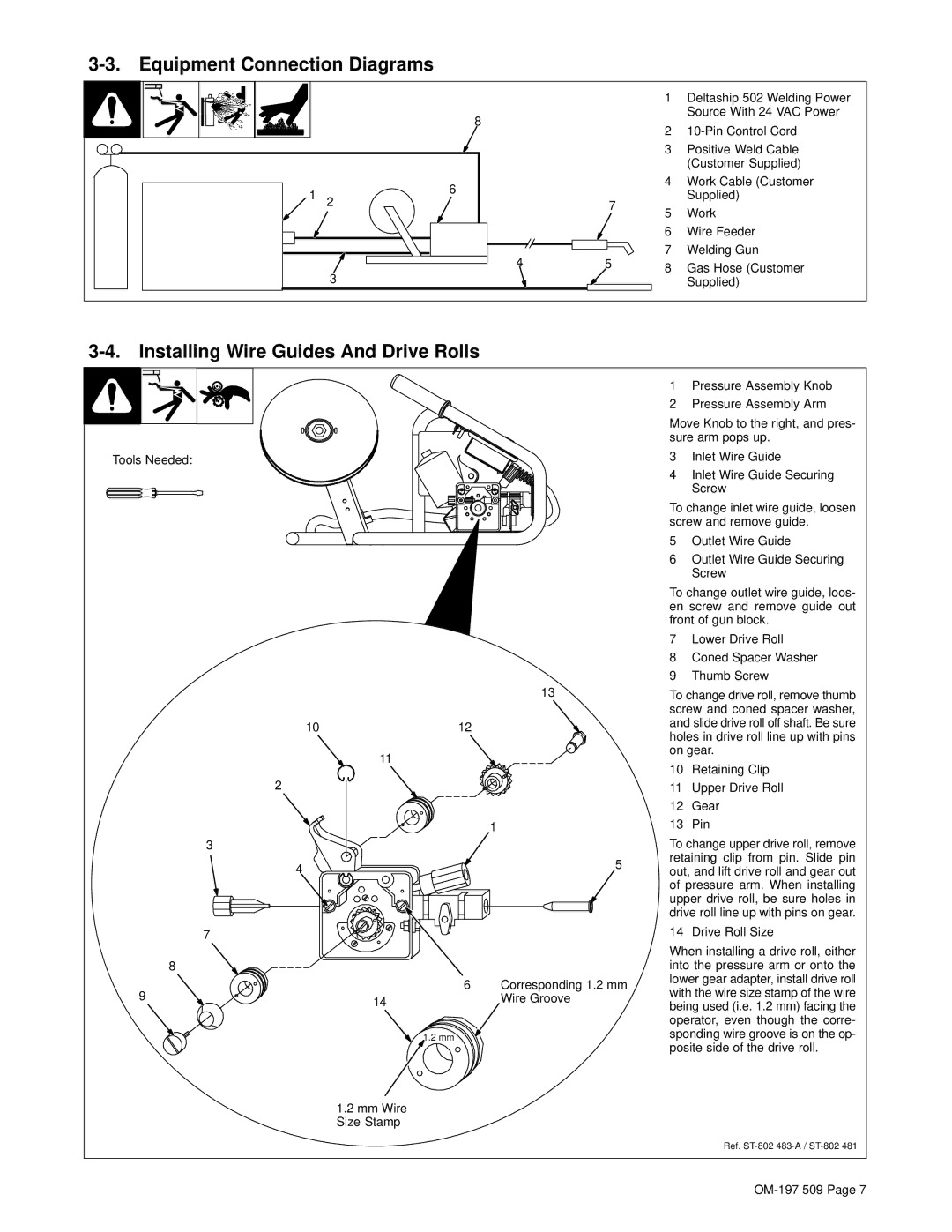

3-3. Equipment Connection Diagrams

1 Deltaship 502 Welding Power

Source With 24 VAC Power

8

2

1 | 6 |

|

2 | 7 | |

|

| |

| 4 | 5 |

| 3 |

|

3Positive Weld Cable (Customer Supplied)

4Work Cable (Customer Supplied)

5Work

6Wire Feeder

7Welding Gun

8Gas Hose (Customer Supplied)

3-4. Installing Wire Guides And Drive Rolls

Tools Needed:

|

| 13 |

10 | 12 |

|

| 11 |

|

2 |

|

|

|

| 1 |

3 |

|

|

4 |

| 5 |

|

| |

7 |

|

|

8 |

|

|

9 | 6 | Corresponding 1.2 mm |

14 | Wire Groove | |

|

| |

| 1.2 mm |

|

1Pressure Assembly Knob

2Pressure Assembly Arm

Move Knob to the right, and pres- sure arm pops up.

3Inlet Wire Guide

4Inlet Wire Guide Securing Screw

To change inlet wire guide, loosen screw and remove guide.

5Outlet Wire Guide

6Outlet Wire Guide Securing Screw

To change outlet wire guide, loos- en screw and remove guide out front of gun block.

7Lower Drive Roll

8Coned Spacer Washer

9Thumb Screw

To change drive roll, remove thumb screw and coned spacer washer, and slide drive roll off shaft. Be sure holes in drive roll line up with pins on gear.

10Retaining Clip

11Upper Drive Roll

12Gear

13Pin

To change upper drive roll, remove retaining clip from pin. Slide pin out, and lift drive roll and gear out of pressure arm. When installing upper drive roll, be sure holes in drive roll line up with pins on gear.

14 Drive Roll Size

When installing a drive roll, either into the pressure arm or onto the lower gear adapter, install drive roll with the wire size stamp of the wire being used (i.e. 1.2 mm) facing the operator, even though the corre- sponding wire groove is on the op- posite side of the drive roll.

1.2mm Wire Size Stamp

Ref.