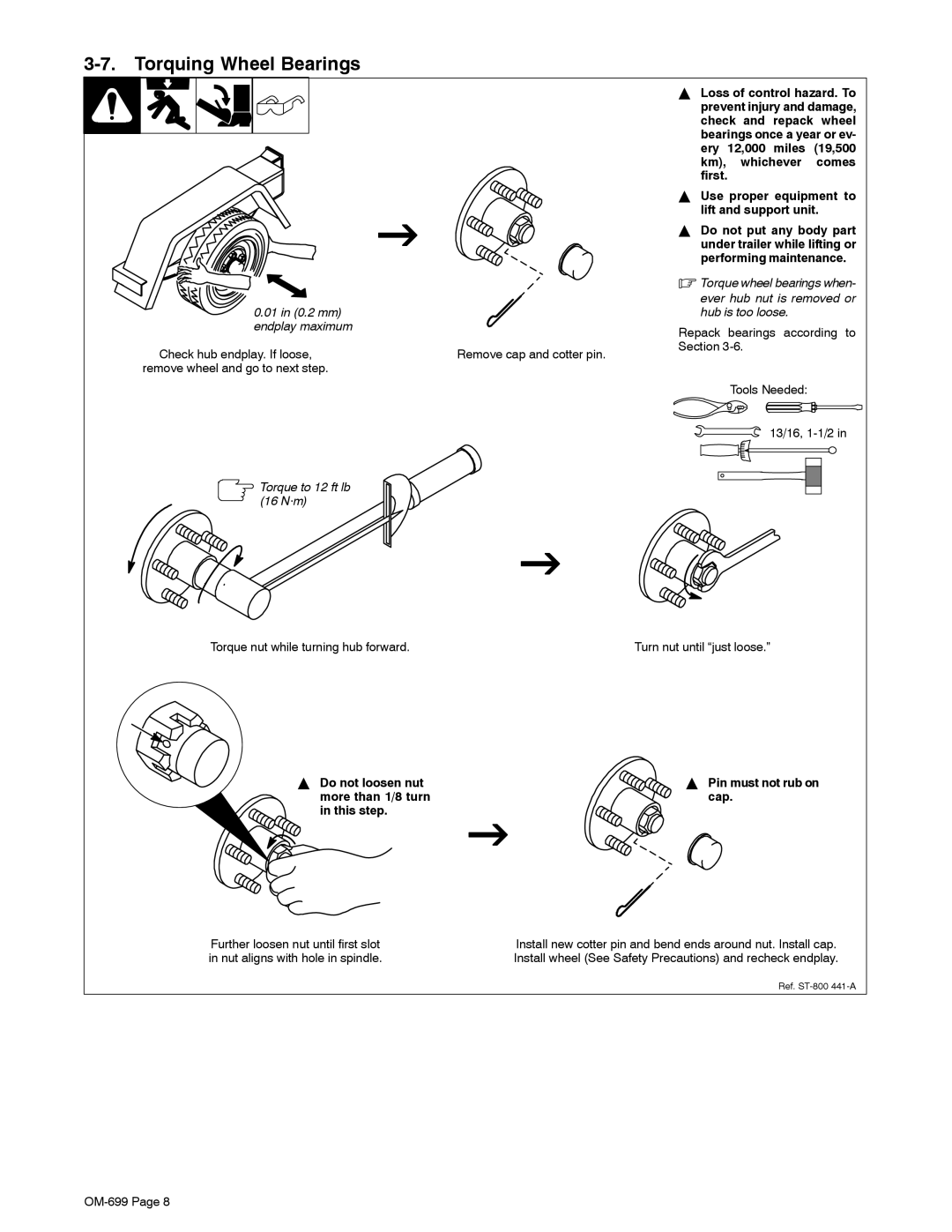

3-7. Torquing Wheel Bearings

|

| Y Loss of control hazard. To | ||

|

| prevent injury and damage, | ||

|

| check and repack | wheel | |

|

| bearings once a year or ev- | ||

|

| ery | 12,000 miles | (19,500 |

|

| km), | whichever | comes |

|

| first. |

| |

|

| Y Use proper equipment to | ||

|

| lift and support unit. | ||

|

| Y Do not put any body part | ||

|

| under trailer while lifting or | ||

|

| performing maintenance. | ||

|

| . Torque wheel bearings when- | ||

|

| ever hub nut is removed or | ||

0.01 in (0.2 mm) |

| hub is too loose. |

| |

endplay maximum |

| Repack | bearings according to | |

|

| |||

Check hub endplay. If loose, | Remove cap and cotter pin. | Section |

| |

|

|

| ||

remove wheel and go to next step.

Tools Needed:

13/16,

Torque to 12 ft lb (16 N·m)

Torque nut while turning hub forward. | Turn nut until “just loose.” |

YDo not loosen nut more than 1/8 turn in this step.

YPin must not rub on cap.

Further loosen nut until first slot in nut aligns with hole in spindle.

Install new cotter pin and bend ends around nut. Install cap. Install wheel (See Safety Precautions) and recheck endplay.

Ref.