Installing and Removing Blades from the

Remove battery pack before changing blades. Make sure the spindle and blade clamp areas are clean. Metal chips and sawdust may prevent the

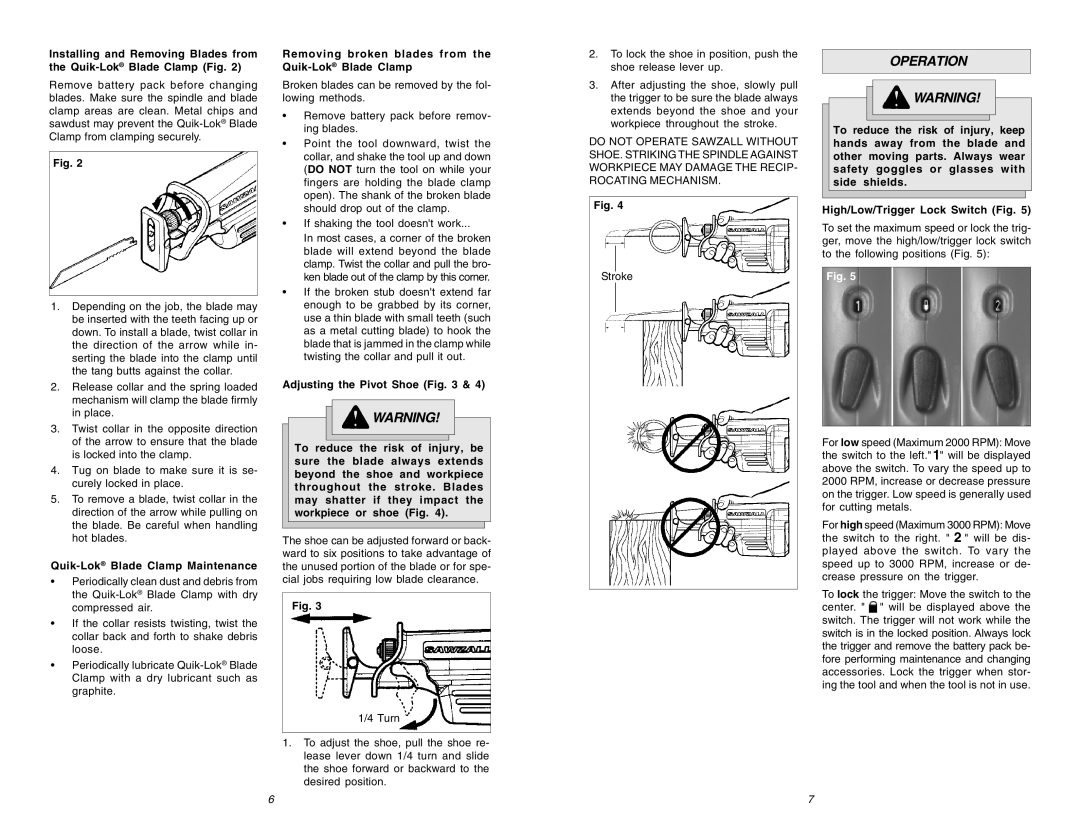

Fig. 2

1.Depending on the job, the blade may be inserted with the teeth facing up or down. To install a blade, twist collar in the direction of the arrow while in- serting the blade into the clamp until the tang butts against the collar.

2.Release collar and the spring loaded mechanism will clamp the blade firmly in place.

3.Twist collar in the opposite direction of the arrow to ensure that the blade is locked into the clamp.

4.Tug on blade to make sure it is se- curely locked in place.

5.To remove a blade, twist collar in the direction of the arrow while pulling on the blade. Be careful when handling hot blades.

Quik-Lok® Blade Clamp Maintenance

•Periodically clean dust and debris from the

•If the collar resists twisting, twist the collar back and forth to shake debris loose.

•Periodically lubricate

Removing broken blades from the Quik-Lok® Blade Clamp

Broken blades can be removed by the fol- lowing methods.

•Remove battery pack before remov- ing blades.

•Point the tool downward, twist the collar, and shake the tool up and down (DO NOT turn the tool on while your fingers are holding the blade clamp open). The shank of the broken blade should drop out of the clamp.

•If shaking the tool doesn't work...

In most cases, a corner of the broken blade will extend beyond the blade clamp. Twist the collar and pull the bro- ken blade out of the clamp by this corner.

•If the broken stub doesn't extend far enough to be grabbed by its corner, use a thin blade with small teeth (such as a metal cutting blade) to hook the blade that is jammed in the clamp while twisting the collar and pull it out.

Adjusting the Pivot Shoe (Fig. 3 & 4)

![]() WARNING!

WARNING!

To reduce the risk of injury, be sure the blade always extends beyond the shoe and workpiece throughout the stroke. Blades may shatter if they impact the workpiece or shoe (Fig. 4).

The shoe can be adjusted forward or back- ward to six positions to take advantage of the unused portion of the blade or for spe- cial jobs requiring low blade clearance.

Fig. 3

1/4 Turn

1.To adjust the shoe, pull the shoe re- lease lever down 1/4 turn and slide the shoe forward or backward to the desired position.

2.To lock the shoe in position, push the shoe release lever up.

3.After adjusting the shoe, slowly pull the trigger to be sure the blade always extends beyond the shoe and your workpiece throughout the stroke.

DO NOT OPERATE SAWZALL WITHOUT SHOE. STRIKING THE SPINDLE AGAINST WORKPIECE MAY DAMAGE THE RECIP- ROCATING MECHANISM.

Fig. 4

Stroke

OPERATION

![]() WARNING!

WARNING!

To reduce the risk of injury, keep hands away from the blade and other moving parts. Always wear safety goggles or glasses with side shields.

High/Low/Trigger Lock Switch (Fig. 5)

To set the maximum speed or lock the trig- ger, move the high/low/trigger lock switch to the following positions (Fig. 5):

Fig. 5

For low speed (Maximum 2000 RPM): Move the switch to the left." 1" will be displayed above the switch. To vary the speed up to 2000 RPM, increase or decrease pressure on the trigger. Low speed is generally used for cutting metals.

For high speed (Maximum 3000 RPM): Move the switch to the right. " 2 " will be dis- played above the switch. To vary the speed up to 3000 RPM, increase or de- crease pressure on the trigger.

To lock the trigger: Move the switch to the center. " ![]() " will be displayed above the switch. The trigger will not work while the switch is in the locked position. Always lock the trigger and remove the battery pack be- fore performing maintenance and changing accessories. Lock the trigger when stor- ing the tool and when the tool is not in use.

" will be displayed above the switch. The trigger will not work while the switch is in the locked position. Always lock the trigger and remove the battery pack be- fore performing maintenance and changing accessories. Lock the trigger when stor- ing the tool and when the tool is not in use.

6 | 7 |