To start the drill:

1.Push the magnet button to activate the magnet.

2.Make sure the red indicator light is on. If the light is flashing, check for the fol- lowing:

•Low voltage at plug

•Loose motor connection

•Mag panel buttons are jammed or stuck

If flashing light still occurs, take en- tire unit to an authorized service center.

3.Push a drill button for forward or re- verse.

If a loss of line voltage occurs while the drill is running, the drill will stop.

Gear Shift Lever

Fig. 7

Cat. Nos.

To change speeds, turn the drill off and rotate the lever up or down while the drill is coast- ing to a stop.

NOTE: To avoid damage to the gearbox, do not shift at full speed, when the tool is under load, or when the tool has stopped.

The gear shift on the motor is labeled:

L- for low speed H - for high speed

Typical Operation

1.Insert the bit into the chuck or socket (see “Keyed Chuck" or "Morse Taper Socket” and “Using Twist Drills" and "Using MILWAUKEE STEEL HAWG™ Cutters”).

2.Place the magnetic drill press on a prepared surface.

3.Position the unit so that the tip of the drill bit is directly over the center of the hole to be drilled.

4.Push the magnet button. The red indica- tor light will turn on.

5.Attach the safety chain if drilling over- head or on a vertical surface.

6.Check the gear speed setting and change if required.

7.Push the forward or reverse button as required.

8.Drill hole (see “Using Twist Drills" and "Using MILWAUKEE STEEL HAWG™ Cutters”).

9.Push the “Drill Off” button.

10.Remove the chain (if drilling overhead or on a vertical surface).

11.Push the magnet button. The red indica- tor light will turn off.

Using the Adjustable Base (4203 only)

Fig. 8

1.Turn the drill motor off.

2.Position the magnetic base so that the drill bit is near the desired hole location and push the magnet button. The red indicator light will turn on.

3.Loosen the adjusting handle located at the back of the housing base. Move the housing to position the drill bit over the center of the hole. Tighten the adjusting handle securely.

Keyed Chuck (Select Models)

Fig. 9

1.Open the chuck jaws wide enough to insert the bit. Be sure the shank and the chuck jaws are clean. Dirt particles may prevent the bit from lining up properly.

2.When using drill bits, insert the bit into the chuck. Center the bit in the chuck jaws and lift it about 1/32" off of the bot- tom. Tighten the chuck jaws by hand to align the bit.

3.Place the chuck key in each of the three holes in the chuck, turning it clockwise as shown below. Tighten securely.

4.To remove the bit, insert the chuck key into one of the three holes in the chuck and turn it counterclockwise.

![]() - Clockwise (Tighten)

- Clockwise (Tighten)

![]() - Counterclockwise (Loosen)

- Counterclockwise (Loosen)

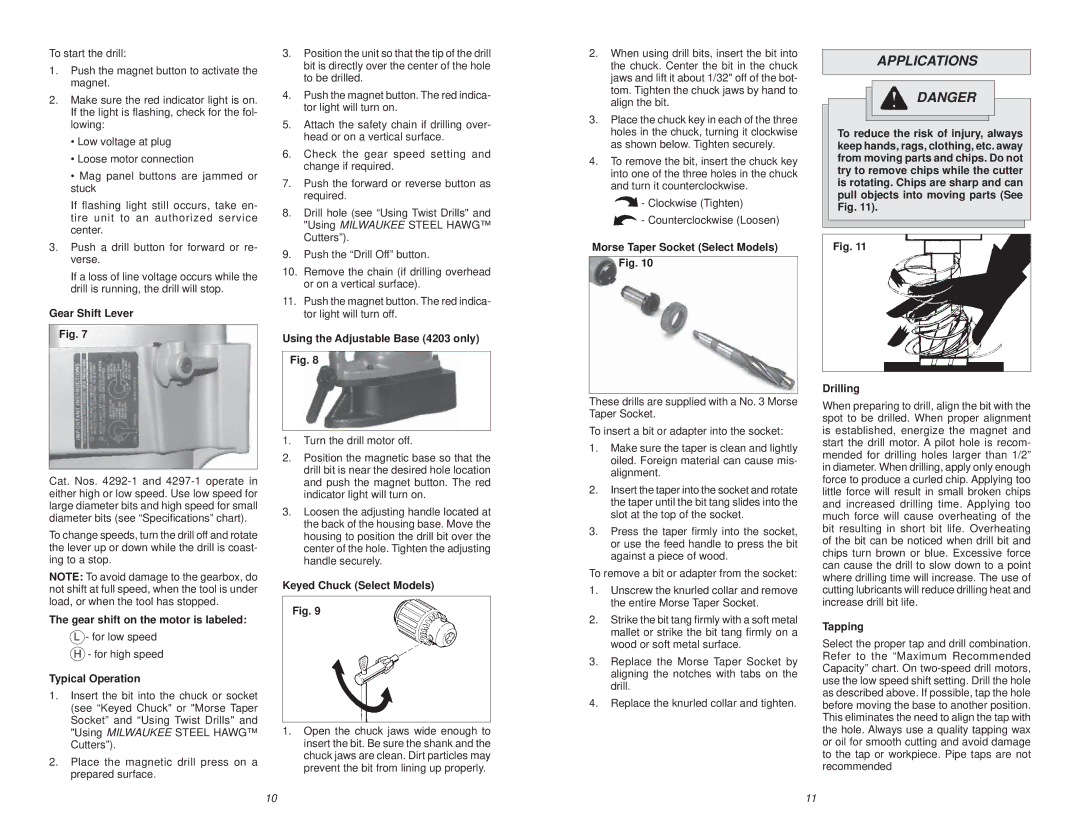

Morse Taper Socket (Select Models)

Fig. 10

These drills are supplied with a No. 3 Morse Taper Socket.

To insert a bit or adapter into the socket:

1.Make sure the taper is clean and lightly oiled. Foreign material can cause mis- alignment.

2.Insert the taper into the socket and rotate the taper until the bit tang slides into the slot at the top of the socket.

3.Press the taper firmly into the socket, or use the feed handle to press the bit against a piece of wood.

To remove a bit or adapter from the socket:

1.Unscrew the knurled collar and remove the entire Morse Taper Socket.

2.Strike the bit tang firmly with a soft metal mallet or strike the bit tang firmly on a wood or soft metal surface.

3.Replace the Morse Taper Socket by aligning the notches with tabs on the drill.

4.Replace the knurled collar and tighten.

APPLICATIONS

DANGER

To reduce the risk of injury, always keep hands, rags, clothing, etc. away from moving parts and chips. Do not try to remove chips while the cutter is rotating. Chips are sharp and can pull objects into moving parts (See Fig. 11).

Fig. 11

Drilling

When preparing to drill, align the bit with the spot to be drilled. When proper alignment is established, energize the magnet and start the drill motor. A pilot hole is recom- mended for drilling holes larger than 1/2” in diameter. When drilling, apply only enough force to produce a curled chip. Applying too little force will result in small broken chips and increased drilling time. Applying too much force will cause overheating of the bit resulting in short bit life. Overheating of the bit can be noticed when drill bit and chips turn brown or blue. Excessive force can cause the drill to slow down to a point where drilling time will increase. The use of cutting lubricants will reduce drilling heat and increase drill bit life.

Tapping

Select the proper tap and drill combination. Refer to the “Maximum Recommended Capacity” chart. On

10 | 11 |