Operating

Position the tool, grasp the handles firmly

6. After you have finished drilling the hole, |

hold the tool upwards, pointing it away |

from your body, and run it briefly in |

APPLICATIONS

and pull the trigger. Always hold the tool se- curely using both handles to maintain control. This tool has been designed to achieve top performance with only moderate pressure. Let the tool do the work.

If the speed begins to drop off when drilling large or deep holes, pull the bit partially out of the hole while the tool is running to help clear dust. Do not use water to settle the dust since it will clog the bit flutes and tend to make the bit bind in the hole. If the bit should bind, a

Using Core Bits

Core bits are useful for drilling large holes for conduit and pipe. MILWAUKEE

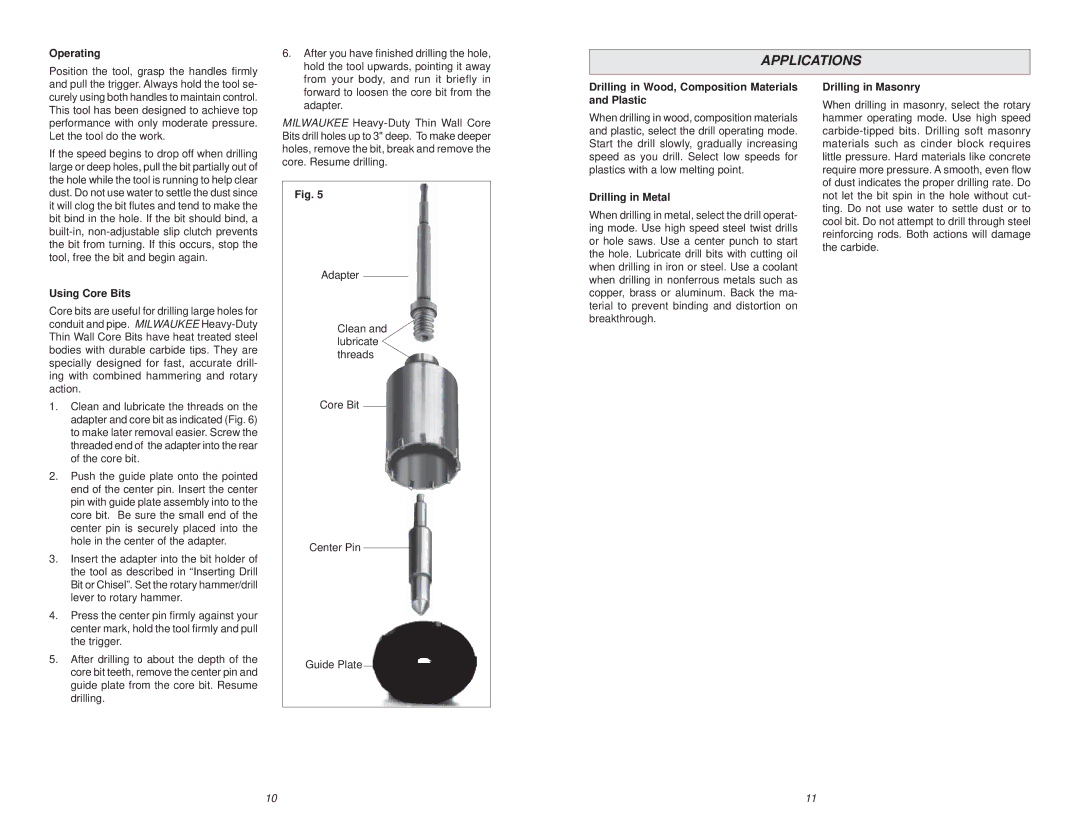

1.Clean and lubricate the threads on the adapter and core bit as indicated (Fig. 6) to make later removal easier. Screw the threaded end of the adapter into the rear of the core bit.

2.Push the guide plate onto the pointed end of the center pin. Insert the center pin with guide plate assembly into to the core bit. Be sure the small end of the center pin is securely placed into the hole in the center of the adapter.

3.Insert the adapter into the bit holder of the tool as described in “Inserting Drill Bit or Chisel”. Set the rotary hammer/drill lever to rotary hammer.

4.Press the center pin firmly against your center mark, hold the tool firmly and pull the trigger.

5.After drilling to about the depth of the core bit teeth, remove the center pin and guide plate from the core bit. Resume drilling.

forward to loosen the core bit from the |

adapter. |

MILWAUKEE

Fig. 5

Adapter

Clean and lubricate threads

Core Bit

Center Pin

Guide Plate

Drilling in Wood, Composition Materials and Plastic

When drilling in wood, composition materials and plastic, select the drill operating mode. Start the drill slowly, gradually increasing speed as you drill. Select low speeds for plastics with a low melting point.

Drilling in Metal

When drilling in metal, select the drill operat- ing mode. Use high speed steel twist drills or hole saws. Use a center punch to start the hole. Lubricate drill bits with cutting oil when drilling in iron or steel. Use a coolant when drilling in nonferrous metals such as copper, brass or aluminum. Back the ma- terial to prevent binding and distortion on breakthrough.

Drilling in Masonry

When drilling in masonry, select the rotary hammer operating mode. Use high speed

10 | 11 |