11

MICROPROCESSOR CONTROL

MICROPROCESSOR CONTROL

C.Low Ambient Temperature Switch (LATS) - The purpose of this switch is to extend cooling operation in low outdoor temperatures as low as 25°. The outdoor unit uses a high side pressure switch to cycle the fan. When pressure drops to 165 PSI

During low ambient cooling operation the indoor unit may initiate an “air defrost” of the indoor coil once during every 16 minutes of continuous cooling operation. This insures that the coil has adequate airflow and should not be considered as a fault.

D.Defrost Sensor Switch - The defrost switch is set to close at 35 degrees

E.Crankcase Heater (CCH) - A crankcase heater is installed into all PUGH heat pump units to protect the compressor. When line voltage is first applied to the outdoor unit, the control will energize the crankcase heater. The control will continue to energize the CCH until the first call for compressor operation. The control never energizes the CCH during compressor operation. The control will energize the CCH thirty minutes after the compressor turns off. It will then cycle the CCH on for 30 minutes and off for 30 minutes repeatedly until the compressor is again turned on.

F.Compressor Contactor (CC) - The compressor contactor is energized with 24VAC when a 12 VDC is input to the out- door unit on control wires 1 and 2 from the indoor unit. This 12 VDC signal is generated and sent from the indoor unit on all calls for compressor operation.

G.Outdoor Fan Motor (ODF) - The outdoor fan motor typically operates at the same time as the compressor. However, the fan may be off while the compressor is operating during low ambient cooling conditions as described previously.

H.Transformer Input (24VAC) - The secondary side of the transformer supplies 24 volts AC to the circuit board on the “24VAC” terminals. This voltage operates the internal circuits of the board and also provides voltage to the compressor contactor when appropriate. The primary side of the transformer is powered with line voltage from terminals marked “L1” and “L2” on the board.

I.Line Voltage - Line voltage is input and output from the circuit board on the terminals marked “L1” and “L2”. There are four terminals marked “L1”. These terminals provide “L1” input to the board and “L1” output to the transformer, crank- case heater and the outdoor fan motor.

There are two terminals marked “L2”. One terminal provides “L2” line voltage input to the board. The other provides “L2” output to the transformer.

J.

K.Time Shortening - Placing the defrost jumper to the “TEST” position shortens timings of the control to the following values.

1.

2.CCH Cycles - 24 seconds

3.Compressor Run - 1 second

4.Low Pressure Bypass - 12 seconds

L.Last Fault Memory Recall. The control maintains a memory of the last fault that occurred. The last fault code can be recalled by moving the defrost jumper to the “TEST” position and observing the “STATUS” LED display. The control stores only the last fault code. The control will reset the fault code memory when the line voltage to the outdoor unit is turned off.

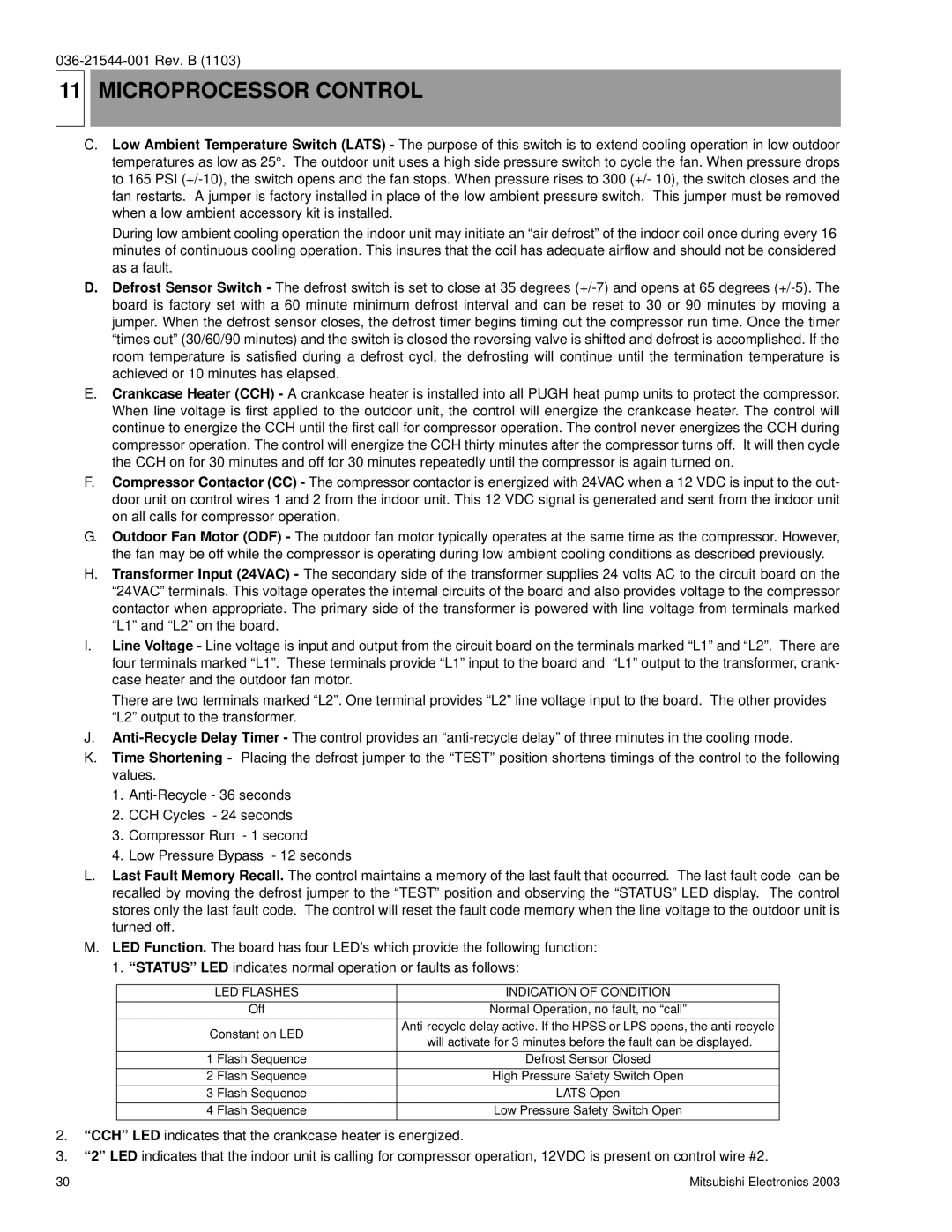

M.LED Function. The board has four LED’s which provide the following function:

1.“STATUS” LED indicates normal operation or faults as follows:

LED FLASHES | INDICATION OF CONDITION | |

Off | Normal Operation, no fault, no “call” | |

Constant on LED | ||

will activate for 3 minutes before the fault can be displayed. | ||

| ||

1 Flash Sequence | Defrost Sensor Closed | |

2 Flash Sequence | High Pressure Safety Switch Open | |

3 Flash Sequence | LATS Open | |

4 Flash Sequence | Low Pressure Safety Switch Open |

2.“CCH” LED indicates that the crankcase heater is energized.

3.“2” LED indicates that the indoor unit is calling for compressor operation, 12VDC is present on control wire #2.

30 | Mitsubishi Electronics 2003 |