GB

9. Additional refrigerant charge

At the time of shipping, the heat source unit is charged with the refrigerant. As this charge does not include the amount needed for extended piping, additional charg- ing for each refrigerant line will be required on site. In order that future servicing may be properly provided, always keep a record of the size and length of each refrigerant line and the amount of additional charge by writing it in the space pro- vided on the heat source unit.

9.1.Calculation of additional refrigerant charge

•Calculate the amount of additional charge based on the length of the piping extension and the size of the refrigerant line.

•Use the table to the below as a guide to calculating the amount of additional charging and charge the system accordingly.

•If the calculation results in a fraction of less than 0.1 kg [4 oz], round up to the next 0.1 kg [4 oz]. For example, if the result of the calculation was 8.48 kg [277.4 oz], round the result up to 8.5 kg [280 oz].

<Additional Charge>

Additional |

|

| Liquid pipe size |

| Liquid pipe size |

|

| Liquid pipe size |

|

| ||

refrigerant charge |

| Total length of |

| Total length of |

|

| Total length of |

|

| |||

|

| = | ø12.7 [1/2] | + | ø9.52 [3/8] |

| + | ø6.35 [1/4] |

| + α | ||

(kg) [oz] |

| (m) ⋅ 0.12 (kg/m) |

| (m) ⋅ 0.06 (kg/m) |

|

| (m) ⋅ 0.024 (kg/m) |

|

| |||

|

|

| (in) ⋅ 1.29 (oz/ft) |

| (in) ⋅ 0.65 (oz/ft) |

|

| (in) ⋅ 0.26 (oz/ft) |

|

| ||

<Example> |

|

|

|

|

|

|

|

|

|

|

|

|

Indoor 1: 24 | A: ø9.52 [3/8] | 40 m [131 ft] a: ø9.52 [3/8] | 10 m [32 ft] | At the |

| |||||||

2: 36 | B: ø9.52 [3/8] | 10 m [32 ft] | b: ø9.52 [3/8] | 5 m | [16 ft] |

| ||||||

3: 15 | C: ø9.52 [3/8] | 15 m [49 ft] | c: ø6.35 [1/4] | 10 m [32 ft] | conditions | |||||||

4: 12 | D: ø9.52 [3/8] | 10 m [32 ft] | d: ø6.35 [1/4] | 10 m [32 ft] | below: |

| ||||||

5: 24 |

|

|

|

|

| e: ø9.52 [3/8] | 10 m [32 ft] |

|

|

| ||

The total length of each liquid line is as follows: |

|

|

|

|

|

| ||||||

ø9.52 [3/8]: A + B + C + D + a + b + e = 40 [131] + 10 [32] + 15 [49] + 10 [32] |

| |||||||||||

|

|

|

|

|

| + 10 [32] + 5 [16] + 10 [32] |

|

|

| |||

= 100 m [292 ft]

ø6.35 [1/4]: c + d = 10 [32] + 10 [32] = 20 m [64 ft] Therefore,

<Calculation example> Additional refrigerant charge

= 100 [292] ⋅ 0.06 [0.65] + 20 [64] ⋅ 0.024 [0.26] + 2.0 [71] = 8.5 kg [280 oz]

Value of α |

|

|

|

Total capacity of connecting indoor units | α |

|

|

Models 31 to 60 | 1.5 kg [53 oz] |

|

|

Models 61 to 126 | 2.0 kg [71 oz] |

|

|

9.2.Precautions concerning piping connec- tion and valve operation

•Conduct piping connection and valve operation accurately.

•Flange type side connecting pipe is assembled in factory before shipment.

1For brazing to the connecting pipe with flange, remove the connecting pipe with flange from the ball valve, and braze it outside of the unit.

2During the time when removing the connecting pipe with flange, remove the seal attached on the rear side of this sheet and paste it onto the flange surface of the ball valve to prevent the entry of dust into the valve.

3The refrigerant circuit is closed with a round,

4At the mounting of the hollow packing, wipe off dust attached on the flange sheet surface and the packing. Coat refrigerating machine oil (Ester oil, ether oil or alkylbenzene [small amount]) onto both surfaces of the pack- ing.

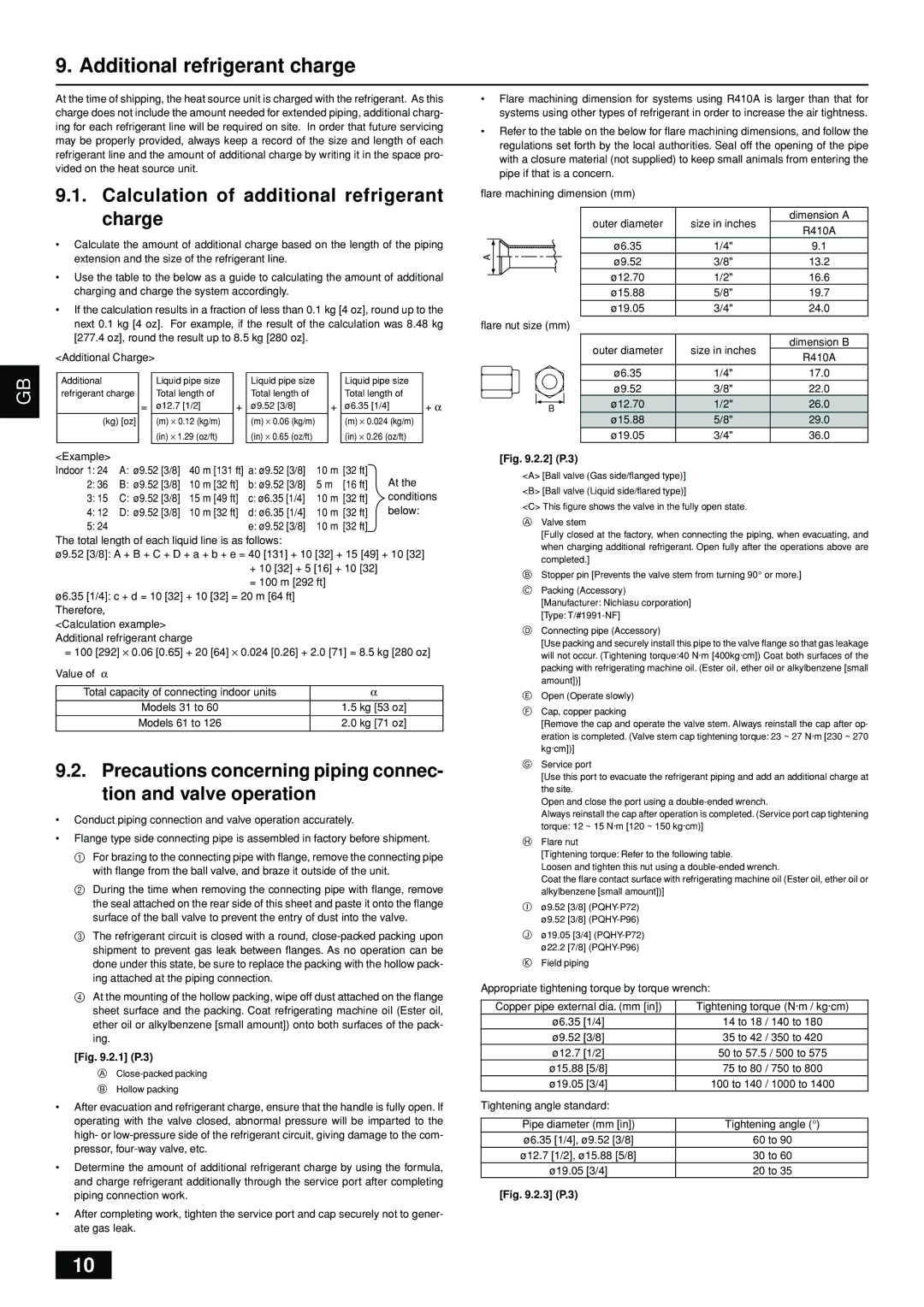

[Fig. 9.2.1] (P.3)

A

BHollow packing

•After evacuation and refrigerant charge, ensure that the handle is fully open. If operating with the valve closed, abnormal pressure will be imparted to the high- or

•Determine the amount of additional refrigerant charge by using the formula, and charge refrigerant additionally through the service port after completing piping connection work.

•After completing work, tighten the service port and cap securely not to gener- ate gas leak.

•Flare machining dimension for systems using R410A is larger than that for systems using other types of refrigerant in order to increase the air tightness.

•Refer to the table on the below for flare machining dimensions, and follow the regulations set forth by the local authorities. Seal off the opening of the pipe with a closure material (not supplied) to keep small animals from entering the pipe if that is a concern.

flare machining dimension (mm) |

|

| ||

| outer diameter | size in inches | dimension A | |

| R410A | |||

|

|

| ||

| ø6.35 | 1/4" | 9.1 | |

A | ø9.52 | 3/8" | 13.2 | |

| ||||

| ø12.70 | 1/2" | 16.6 | |

| ø15.88 | 5/8" | 19.7 | |

| ø19.05 | 3/4" | 24.0 | |

flare nut size (mm) |

|

|

| |

| outer diameter | size in inches | dimension B | |

| R410A | |||

|

|

| ||

| ø6.35 | 1/4" | 17.0 | |

| ø9.52 | 3/8" | 22.0 | |

B | ø12.70 | 1/2" | 26.0 | |

ø15.88 | 5/8" | 29.0 | ||

| ||||

| ø19.05 | 3/4" | 36.0 | |

[Fig. 9.2.2] (P.3)

<A> [Ball valve (Gas side/flanged type)]

<B> [Ball valve (Liquid side/flared type)]

<C> This figure shows the valve in the fully open state.

AValve stem

[Fully closed at the factory, when connecting the piping, when evacuating, and when charging additional refrigerant. Open fully after the operations above are completed.]

BStopper pin [Prevents the valve stem from turning 90° or more.]

CPacking (Accessory)

[Manufacturer: Nichiasu corporation]

[Type:

DConnecting pipe (Accessory)

[Use packing and securely install this pipe to the valve flange so that gas leakage will not occur. (Tightening torque:40 N·m [400kg·cm]) Coat both surfaces of the packing with refrigerating machine oil. (Ester oil, ether oil or alkylbenzene [small amount])]

EOpen (Operate slowly)

FCap, copper packing

[Remove the cap and operate the valve stem. Always reinstall the cap after op- eration is completed. (Valve stem cap tightening torque: 23 ~ 27 N·m [230 ~ 270 kg·cm])]

GService port

[Use this port to evacuate the refrigerant piping and add an additional charge at the site.

Open and close the port using a

Always reinstall the cap after operation is completed. (Service port cap tightening torque: 12 ~ 15 N·m [120 ~ 150 kg·cm)]

HFlare nut

[Tightening torque: Refer to the following table.

Loosen and tighten this nut using a

Coat the flare contact surface with refrigerating machine oil (Ester oil, ether oil or alkylbenzene [small amount])]

Iø9.52 [3/8]

Jø19.05 [3/4]

KField piping

Appropriate tightening torque by torque wrench:

Copper pipe external dia. (mm [in]) | Tightening torque (N·m / kg·cm) | |

ø6.35 [1/4] | 14 to 18 | / 140 to 180 |

ø9.52 [3/8] | 35 to 42 | / 350 to 420 |

ø12.7 [1/2] | 50 to 57.5 / 500 to 575 | |

ø15.88 [5/8] | 75 to 80 | / 750 to 800 |

ø19.05 [3/4] | 100 to 140 | / 1000 to 1400 |

Tightening angle standard: |

|

|

|

| |

Pipe diameter (mm [in]) | Tightening angle (°) | |

ø6.35 [1/4], ø9.52 [3/8] | 60 to 90 | |

ø12.7 [1/2], ø15.88 [5/8] | 30 to 60 | |

ø19.05 [3/4] | 20 to 35 | |

[Fig. 9.2.3] (P.3)

10