9.3

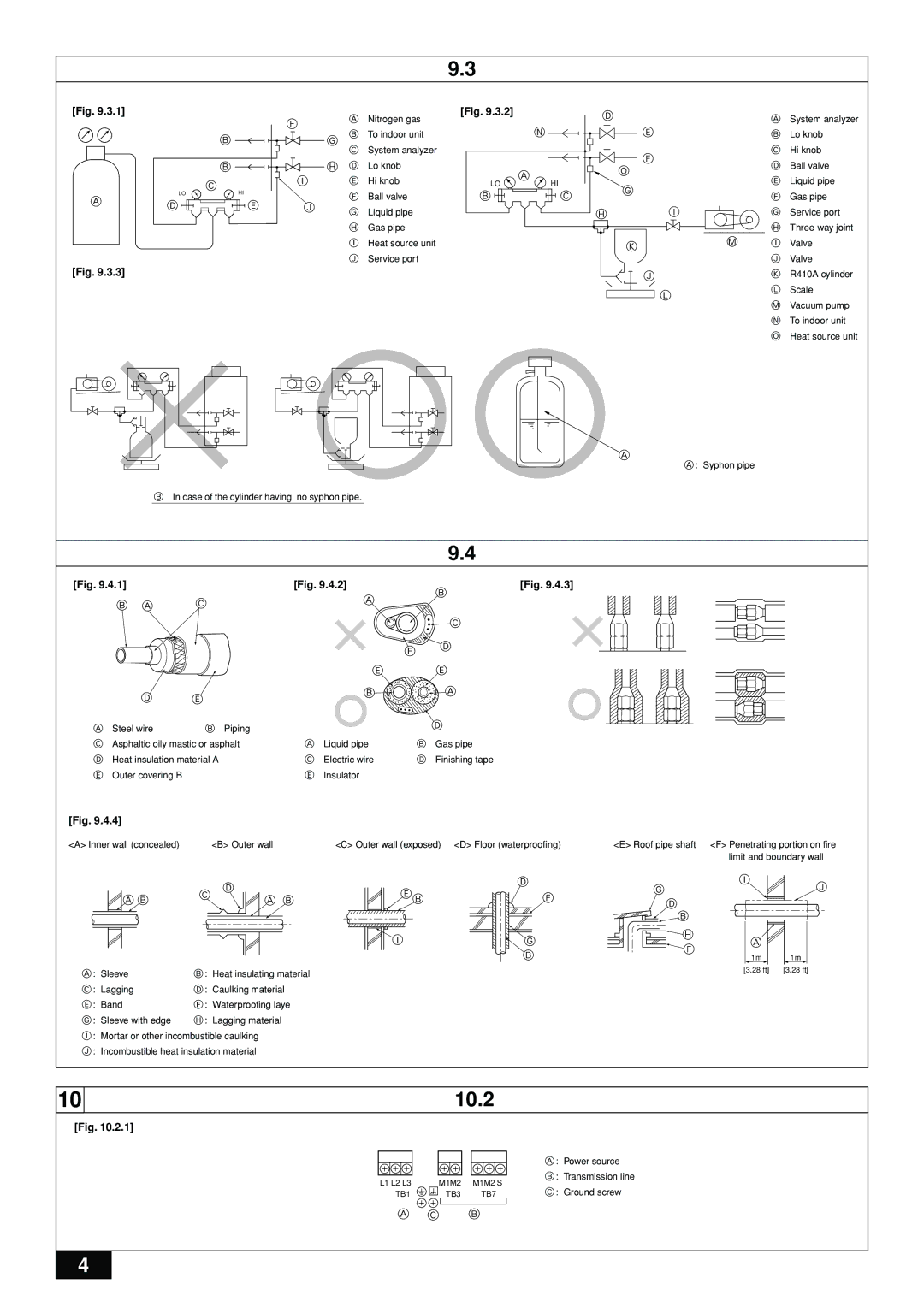

[Fig. 9.3.1]

|

| F | |

|

| B | |

|

| B | |

| C | I | |

LO | HI | ||

|

A

C D E J

[Fig. 9.3.3]

A | Nitrogen gas | [Fig. 9.3.2] | D |

|

|

G B To indoor unit | N |

| E | |

|

|

| ||

C System analyzer |

|

| F | |

H D Lo knob |

|

| ||

A |

| O | ||

E Hi knob |

| |||

HI |

| |||

LO | G | |||

F Ball valve | B | C | ||

| ||||

G Liquid pipe |

| H | I | |

H Gas pipe |

|

|

| |

I Heat source unit |

|

| K | |

|

|

|

JService port

J

L

ASystem analyzer

BLo knob

CHi knob

DBall valve

ELiquid pipe

FGas pipe

GService port

H

MI Valve

J Valve

K R410A cylinder

L Scale

M Vacuum pump

N To indoor unit

O Heat source unit

A

A: Syphon pipe

B In case of the cylinder having no syphon pipe.

9.4

[Fig. 9.4.1]

B A C

DE

A Steel wire | B Piping |

CAsphaltic oily mastic or asphalt

DHeat insulation material A

EOuter covering B

[Fig. 9.4.2] |

| B | [Fig. 9.4.3] |

A |

|

| |

|

|

| |

|

| C |

|

| E | D |

|

|

|

| |

E |

| E |

|

B |

| A |

|

|

| D |

|

A Liquid pipe |

| B Gas pipe |

|

C Electric wire |

| D Finishing tape |

|

EInsulator

[Fig. 9.4.4]

<A> Inner wall (concealed) | <B> Outer wall | <C> Outer wall (exposed) <D> Floor (waterproofing) | <E> Roof pipe shaft <F> Penetrating portion on fire |

|

|

| limit and boundary wall |

A B | C D | A B | EB |

|

|

| I |

A: Sleeve | B: Heat insulating material |

| |

C: Lagging | D: Caulking material |

| |

E: Band | F: Waterproofing laye |

| |

G: Sleeve with edge | H: Lagging material |

| |

I: Mortar or other incombustible caulking

J: Incombustible heat insulation material

D |

| G | I | J |

|

|

| ||

| F |

|

| |

| D |

|

| |

|

|

|

| |

|

| B |

|

|

G |

| H | A |

|

| F |

| ||

B |

| 1m | 1m | |

|

|

[3.28 ft] | [3.28 ft] |

10

10.2

[Fig. 10.2.1]

|

|

| A: Power source | |

L1 L2 L3 | M1M2 | M1M2 S | B: Transmission line | |

C: Ground screw | ||||

TB1 | TB3 | TB7 |

A C B

4