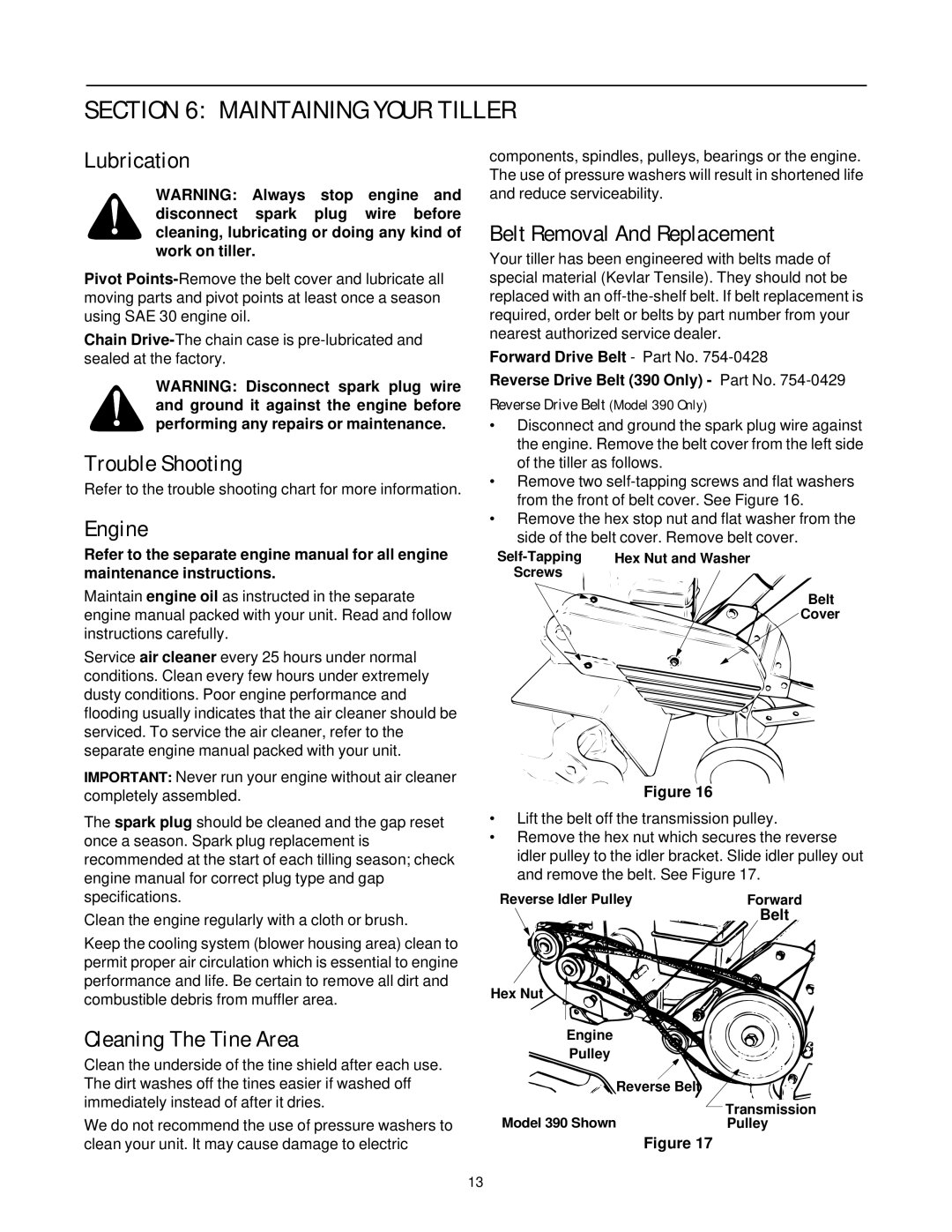

390 Shown specifications

The MTD 390 is a notable product in the range of powerful and efficient garden tools designed for both professional landscapers and avid gardeners. This versatile machine is engineered to tackle various landscaping tasks with precision and ease. Its combination of robust design, cutting-edge technologies, and user-friendly features make it an essential tool for maintaining pristine gardens and outdoor spaces.At the heart of the MTD 390 is its powerful engine that provides reliable performance. The engine is designed for optimal efficiency, ensuring that users can complete their tasks without unnecessary downtime. With a displacement that allows for high torque and consistent power delivery, the MTD 390 easily handles thick grass and dense foliage.

One of the standout features of the MTD 390 is its advanced blade technology. The cutting deck is equipped with precision-engineered blades that provide a clean and even cut, promoting healthy growth in lawns and gardens. The adjustable cutting height allows users to customize their mowing experience, accommodating different grass types and seasonal requirements. This flexibility ensures that every user can achieve the desired lawn appearance.

In addition to its cutting capabilities, the MTD 390 emphasizes comfort and usability. The ergonomic handle design minimizes strain during operation, allowing for extended periods of use without discomfort. The lightweight construction of the machine makes it easy to maneuver, even in tight spaces. Features such as quick-release systems for the cutting deck further enhance the convenience, making maintenance straightforward.

Technology plays a crucial role in the MTD 390's functionality. The machine is equipped with innovative start systems that ensure a swift ignition process, eliminating the frustrations often associated with traditional pull-start mechanisms. Furthermore, the design incorporates efficient fuel consumption, minimizing operating costs while maintaining powerful performance.

Durability is another key characteristic of the MTD 390. The robust frame and high-quality materials used in its construction ensure that it withstands the rigors of frequent use. Whether dealing with challenging terrains or changing weather conditions, the MTD 390 is built to endure, making it a long-term investment for users.

In summary, the MTD 390 stands out as a premium choice for anyone looking to enhance their gardening experience. Its powerful engine, advanced cutting technology, ergonomic design, and durable construction make it a reliable companion for achieving beautiful outdoor spaces. Whether you're a professional landscaper or a weekend warrior, the MTD 390 is equipped to handle all your gardening needs with efficiency and ease.