MAINTENANCE AND REPAIR INSTRUCTIONS

SAW CHAIN REPLACEMENT/INSTALLATION

WARNING: Whenever handling the saw chain,

always wear work gloves for protection against sharp cutting edges.

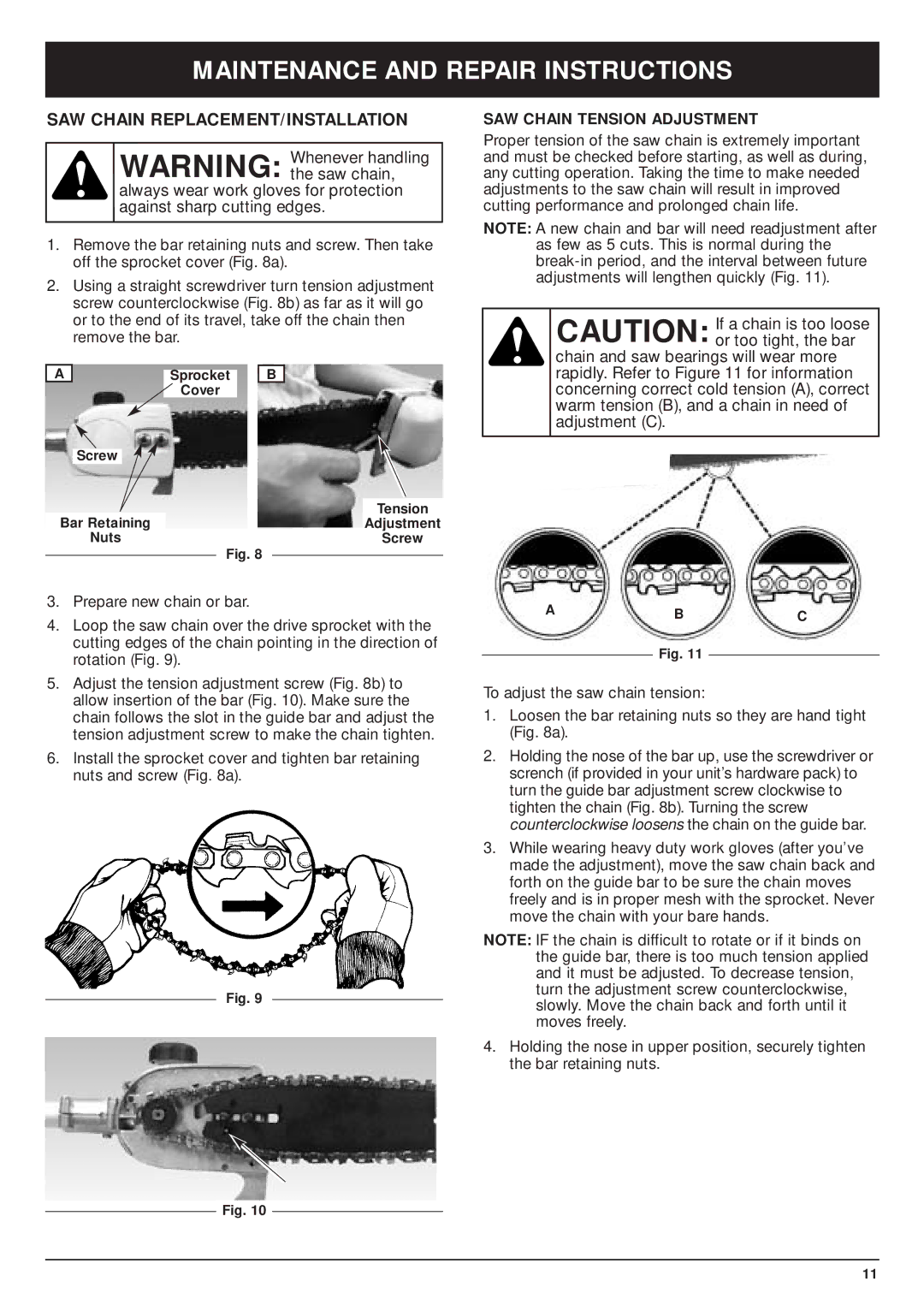

1.Remove the bar retaining nuts and screw. Then take off the sprocket cover (Fig. 8a).

2.Using a straight screwdriver turn tension adjustment screw counterclockwise (Fig. 8b) as far as it will go or to the end of its travel, take off the chain then remove the bar.

A |

|

|

|

|

|

| B |

|

| ||

|

|

| Sprocket |

|

|

| |||||

|

|

|

| Cover |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

| Screw |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Tension |

Bar Retaining |

|

|

|

|

|

| |||||

|

|

|

|

|

|

| Adjustment | ||||

| Nuts |

|

|

|

|

|

|

| Screw | ||

|

|

|

|

| Fig. 8 |

|

|

|

| ||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

3.Prepare new chain or bar.

4.Loop the saw chain over the drive sprocket with the cutting edges of the chain pointing in the direction of rotation (Fig. 9).

5.Adjust the tension adjustment screw (Fig. 8b) to allow insertion of the bar (Fig. 10). Make sure the chain follows the slot in the guide bar and adjust the tension adjustment screw to make the chain tighten.

6.Install the sprocket cover and tighten bar retaining nuts and screw (Fig. 8a).

Fig. 9

SAW CHAIN TENSION ADJUSTMENT

Proper tension of the saw chain is extremely important and must be checked before starting, as well as during, any cutting operation. Taking the time to make needed adjustments to the saw chain will result in improved cutting performance and prolonged chain life.

NOTE: A new chain and bar will need readjustment after as few as 5 cuts. This is normal during the

CAUTION: If a chain is too loose or too tight, the bar

chain and saw bearings will wear more rapidly. Refer to Figure 11 for information concerning correct cold tension (A), correct warm tension (B), and a chain in need of adjustment (C).

ABC

Fig. 11

To adjust the saw chain tension:

1.Loosen the bar retaining nuts so they are hand tight (Fig. 8a).

2.Holding the nose of the bar up, use the screwdriver or scrench (if provided in your unit’s hardware pack) to turn the guide bar adjustment screw clockwise to tighten the chain (Fig. 8b). Turning the screw counterclockwise loosens the chain on the guide bar.

3.While wearing heavy duty work gloves (after you’ve made the adjustment), move the saw chain back and forth on the guide bar to be sure the chain moves freely and is in proper mesh with the sprocket. Never move the chain with your bare hands.

NOTE: IF the chain is difficult to rotate or if it binds on the guide bar, there is too much tension applied and it must be adjusted. To decrease tension, turn the adjustment screw counterclockwise, slowly. Move the chain back and forth until it moves freely.

4.Holding the nose in upper position, securely tighten the bar retaining nuts.

Fig. 10

11