maintenance

![]() CAUTION

CAUTION

Inspection and other services should always be carried out on hard and level ground with the engine shutdown.

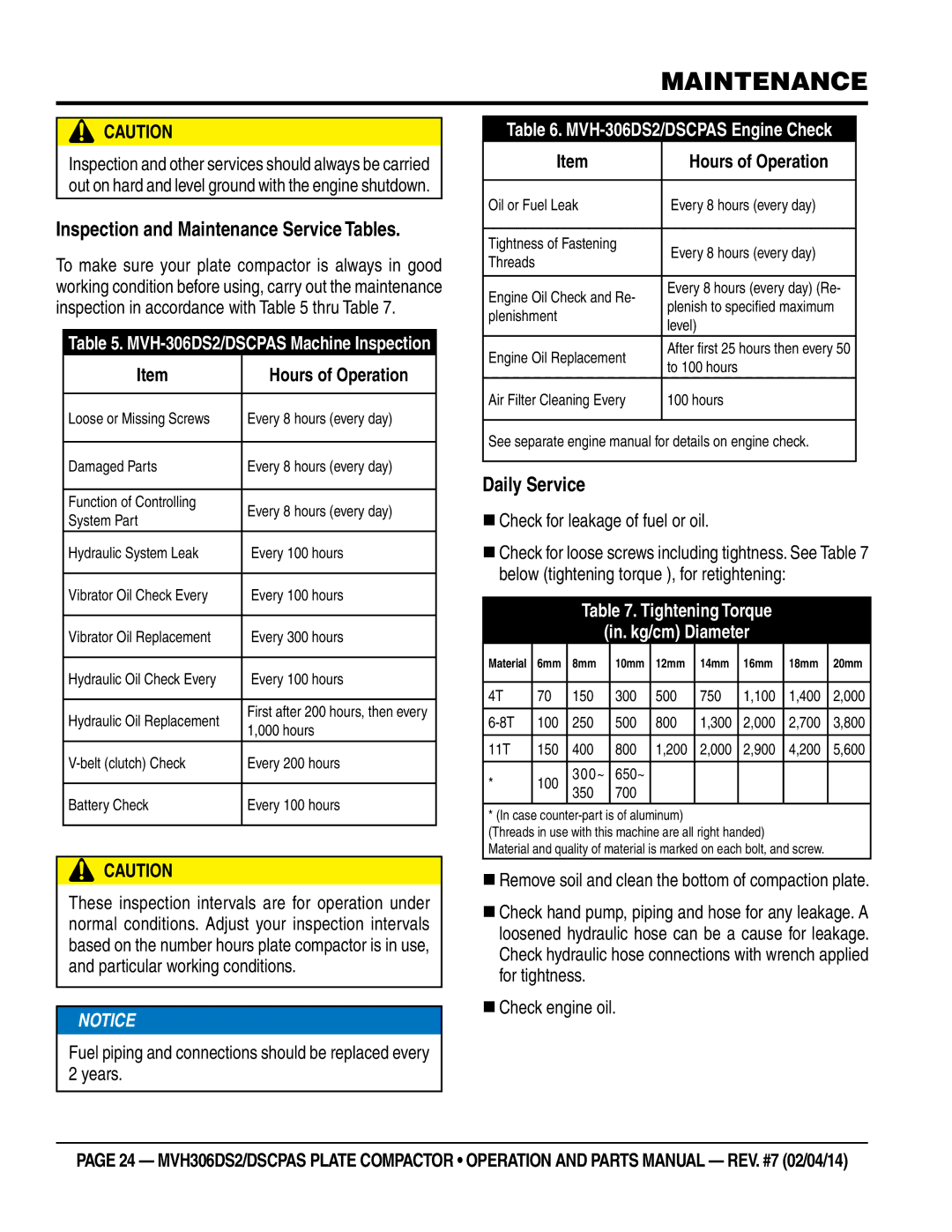

Inspection and Maintenance Service Tables.

To make sure your plate compactor is always in good working condition before using, carry out the maintenance inspection in accordance with Table 5 thru Table 7.

Table 5.

Item | Hours of Operation | |

|

| |

Loose or Missing Screws | Every 8 hours (every day) | |

|

| |

Damaged Parts | Every 8 hours (every day) | |

|

| |

Function of Controlling | Every 8 hours (every day) | |

System Part | ||

| ||

Hydraulic System Leak | Every 100 hours | |

|

| |

Vibrator Oil Check Every | Every 100 hours | |

|

| |

Vibrator Oil Replacement | Every 300 hours | |

|

| |

Hydraulic Oil Check Every | Every 100 hours | |

|

| |

Hydraulic Oil Replacement | First after 200 hours, then every | |

1,000 hours | ||

| ||

Every 200 hours | ||

|

| |

Battery Check | Every 100 hours | |

|

|

![]() CAUTION

CAUTION

These inspection intervals are for operation under normal conditions. Adjust your inspection intervals based on the number hours plate compactor is in use, and particular working conditions.

![]()

![]() NOTICE

NOTICE

Fuel piping and connections should be replaced every 2 years.

Table 6. MVH-306DS2/DSCPAS Engine Check

Item | Hours of Operation | |

|

| |

Oil or Fuel Leak | Every 8 hours (every day) | |

|

| |

Tightness of Fastening | Every 8 hours (every day) | |

Threads | ||

| ||

|

| |

Engine Oil Check and Re- | Every 8 hours (every day) (Re- | |

plenish to specified maximum | ||

plenishment | ||

level) | ||

| ||

Engine Oil Replacement | After first 25 hours then every 50 | |

to 100 hours | ||

| ||

Air Filter Cleaning Every | 100 hours | |

|

|

See separate engine manual for details on engine check.

Daily Service

Check for leakage of fuel or oil.

Check for loose screws including tightness. See Table 7 below (tightening torque ), for retightening:

Table 7. Tightening Torque

(in. kg/cm) Diameter

Material | 6mm | 8mm | 10mm | 12mm | 14mm | 16mm | 18mm | 20mm |

|

|

|

|

|

|

|

|

|

4T | 70 | 150 | 300 | 500 | 750 | 1,100 | 1,400 | 2,000 |

|

|

|

|

|

|

|

|

|

100 | 250 | 500 | 800 | 1,300 | 2,000 | 2,700 | 3,800 | |

|

|

|

|

|

|

|

|

|

11T | 150 | 400 | 800 | 1,200 | 2,000 | 2,900 | 4,200 | 5,600 |

*100 300~ 650~

350 700

* (In case

(Threads in use with this machine are all right handed)

Material and quality of material is marked on each bolt, and screw.

Remove soil and clean the bottom of compaction plate.

Check hand pump, piping and hose for any leakage. A loosened hydraulic hose can be a cause for leakage. Check hydraulic hose connections with wrench applied for tightness.

Check engine oil.

page 24 — mvh306ds2/dsCPAs pLATE COMPACTOR • operation and parts manual — rev. #7 (02/04/14)