DFG Series specifications

The Multiquip DFG Series stands out in the equipment industry due to its powerful performance and advanced technology tailored for a variety of applications. Engineered for durability and efficiency, the DFG Series is specifically designed to meet the demanding needs of contractors, making it an ideal choice for construction, demolition, and industrial projects.One of the hallmark features of the DFG Series is its robust construction. Built with high-quality materials, these models are engineered to withstand harsh working conditions, providing longevity even in the toughest environments. The frames are designed for superior strength, while the engine components are optimized for reliability, ensuring that the equipment remains operational when it's needed the most.

In terms of performance, the DFG Series is equipped with state-of-the-art engines that deliver exceptional power while maintaining fuel efficiency. This balance reduces operating costs and minimizes environmental impact. Users can benefit from increased productivity as these machines are capable of handling heavy loads and challenging tasks with ease.

One of the standout technologies in the DFG Series is the advanced hydraulic system. This system allows for smooth and efficient operation, enabling the equipment to perform a wide range of tasks from lifting and moving materials to grading and leveling. The hydraulics are engineered for precise control, providing operators with enhanced maneuverability and flexibility on job sites.

Additionally, the DFG Series incorporates ergonomic design features aimed at enhancing user comfort and safety. The operator's cabin is spacious and well-appointed with intuitive controls, allowing for easy operation even during long hours of use. Safety is a priority, with features such as reinforced safety barriers, automatic shut-off systems, and well-placed visibility options to ensure that operators remain aware of their surroundings.

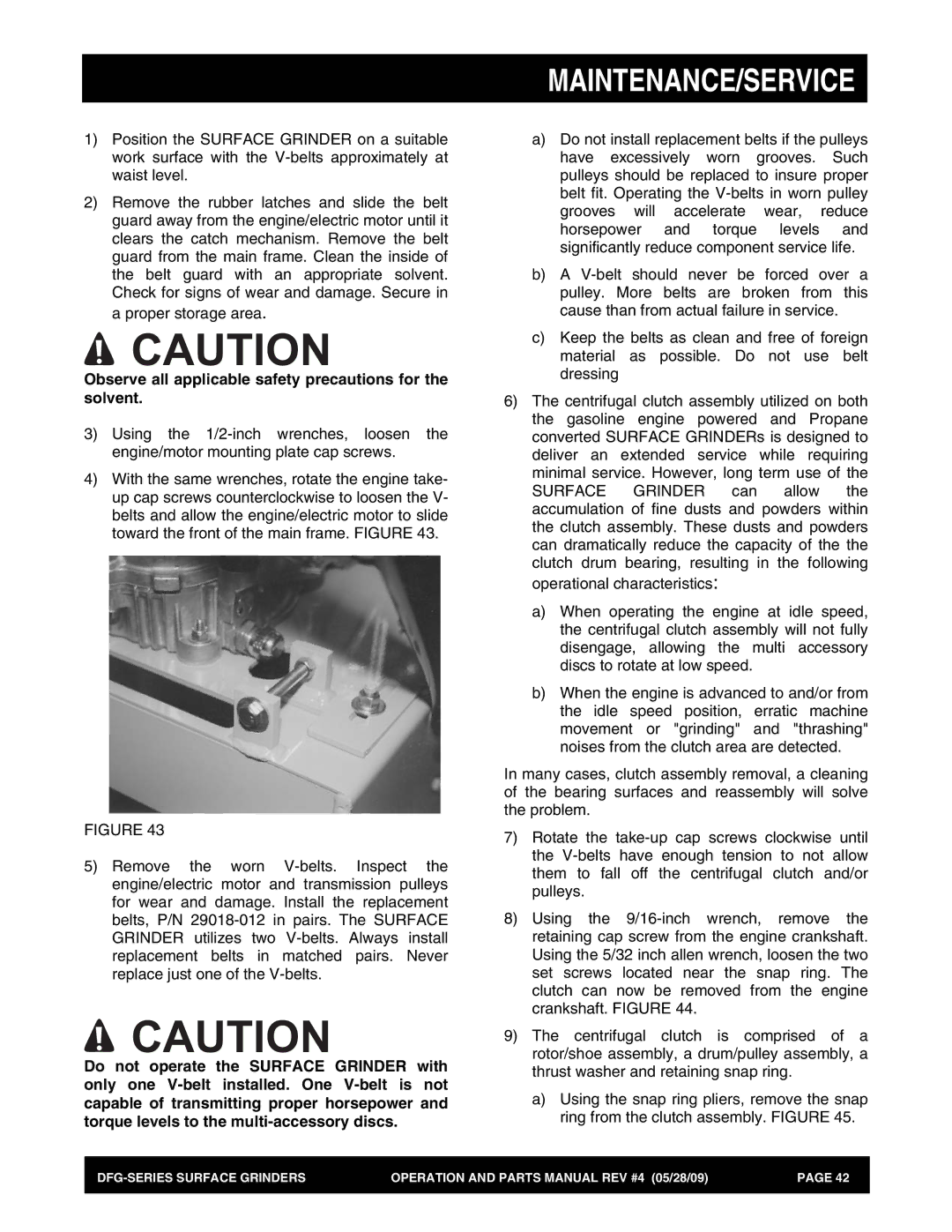

Maintenance is made simple with the DFG Series, which is designed with accessibility in mind. Key components are easily reachable, reducing downtime during servicing and ensuring that the equipment remains in peak operating condition.

Overall, the Multiquip DFG Series blends power, technology, and user-friendly design to provide a versatile solution for today's demanding construction and industrial applications. Whether tasked with heavy lifting, demolition, or ground preparation, the DFG Series remains a reliable choice that will exceed expectations.