HDA-SERIES

Proposition 65 Warning

Page

Table of Contents

Best Deal! Order via Internet Dealers Only

Parts Ordering Procedures

Order via Fax Dealers Only

Training Checklist

Training Checklist

Read Operator’s Manual completely

Machine layout, location of components, checking of engine

Daily PRE-OPERATION Checklist

Daily PRE-OPERATION Checklist

Safety Message Alert Symbols

Do not follow directions

Property, or the surrounding

Always wear approved eye and hearing protection

You do not follow instructions

Rules for Safe Operation

Safety

Rules for Safe Operation

Emergencies

Maintenance Safety

Always know the location of the nearest and first aid kit

Operation and Safety Decals

Operation and Safety Decals

Specifications Trowel

Specifications Trowel

Height Lifting Hook 34.5 in 876.2 mm

Top View SideView

Specifications Engines

Specifications Engines

Model

Honda GX340K1QA2 Honda GX390K1QA2

General Information

General Information

Controls and Components

HDA-SERIES Walk-Behind Trowels

Guard Ring- NEVER! put hands or feet inside guard ring

Basic Engine

Basic Engine

Initial Servicing

Assembly and Installation

Assembly and Installation

HandleTube Installation All Models

Feed the throttle cable through the cable housing

Safety Stop SwitchWire

Handle Height Adjustment

Tighten cable clamp screw and swivel stop screw

Blade Pitch Cable

PRE-INSPECTION

PRE-INSPECTION

Before Starting

Engine Oil Check

Controls

Initial START-UP

Initial START-UP

Lifting the Trowel Onto a Slab Auxiliary Lifting Tube

Lifting Bail Option

Test the Safety Stop Switch

Place the Choke Lever in the Closed position

Operation

Operation

PitchingThe Blades Quick-PitchHandle

Never place your feet or hands inside

Parts while operating this equipment

Guard rings while starting or operating this

Equipment

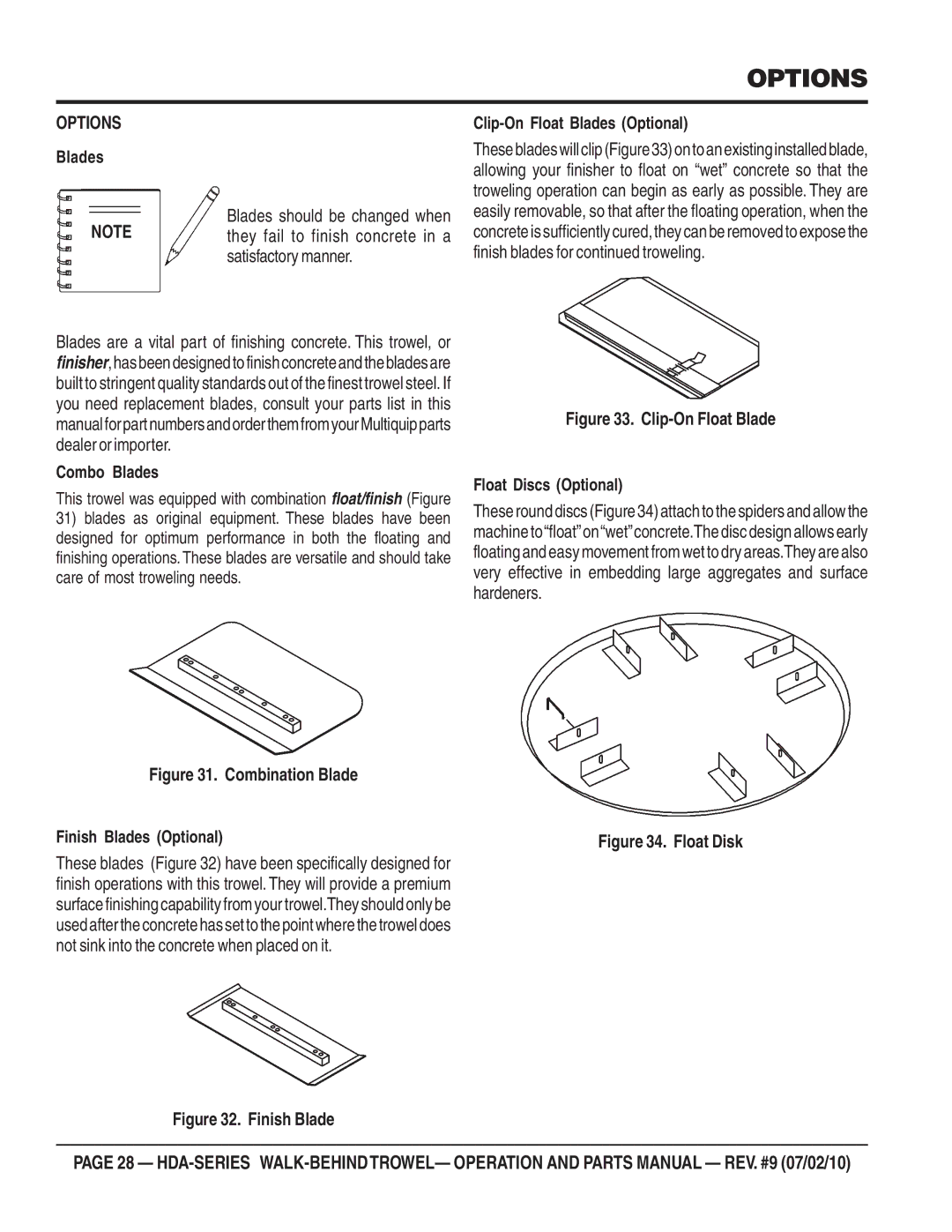

Options

Options

Clip-On Float Blades Optional

Combo Blades

Trowel Arm Adjustment Fixture

Lifting Bail

Maintenance

Maintenance

Maintenance Schedule

Trowel Arm Removal

Spider Removal

Remove the trowel arm from the spider plate

Bronze Bushings Trowel Blade Removal

Trowel Arm Flatness Test

Trowel Arm Adjustment

AdjustmentBolt

Re-Assembly

Locking Nut

Testing

Changing a Blade Belt Removal and Replacement

Before removing the blades

Engine Engine Oil Change

Troubleshooting Trowel

Troubleshooting Trowel

Troubleshooting Trowel

Troubleshooting Engine

Troubleshooting Engine

Explanation of Codes

Xxxxx only Not Used on

Description

Suggested Spare Parts

ARM 16-1/2

Nameplate and Decals

Decal PRE-LOAD Indicator

Service Dept

Decal Power Trowel

Decal QUICK-PITCH Handle

Standard Handle ASSY. OLD Style

Detail B See Detail a

HANDLE, Adjustable

Wire ASSY., Safety Stop Switch

HOUSING, Cable

GRIP, Handle

Standard Handle ASSY. NEW Style

WHEEL, Hand Handle

QUICK-PITCH Handle ASSY. OLD Style

CONNECTOR, QP Control ARM

BLOCK, QP Adjustment

DECAL, Latch Warning

DECAL, Q.P. Warning

QUICK-PITCH Handle ASSY. OLD Style

NUT, QP Trim Control Adjust

SCREW, QP Trim Adjustment

HOUSING, Throttle Cable

DECAL, Arrow

QUICK-PITCH Handle ASSY. NEW Style

PIN, Support Block 3/8 X

Blade Spider Assy

Wear Ring

Flange Bearing

Wear Plate

Bushing

Gearbox & Engine Mounts Assy

SEAL, OIL TCM 10172VTB-H

FLANGE, Countershaft

BEARING, CUP, Timken

BEARING, CONE, Timken

ENGINE, 11 HP Honda Assy

Part Name QTY Remarks

ENGINE, 13 HP Honda Assy

Includes Item W/%

Guard Ring Assy

Part Name QTY. Remarks

9178

Stabilizer Ring Assy

Detail a

WASHER, LOCK, 5/16 MED

1237

Blades & ARM ADJ. Fixture ASSY. Options

0202 Hhcs 5/16-18X1 Ring 0201

1434

1162 a

7281

Lifting Bail ASSY. Option

10229 Hhcs 5/16-24X1 0161 a

2360

Honda GX340K1QA2 AIR Cleaner Assy

ELEMENT, AIR Cleaner

COVER, AIR Cleaner

GROMMET, AIR Cleaner

COLLAR, AIR Cleaner

Honda GX340K1QA2 Camshaft Assy

SPRING, Weight Return

ROD, Push

ARM, Valve Rocker

LIFTER, Valve

Honda GX340K1QA2 Piston Assy

BOLT, Connecting ROD

Ring SET, PISTON- Standard

Ring SET, PISTON- OS

Ring SET, Ppiston

Honda GX340K1QA2 Crankcase Cover Assy

WEIGHT, Governor

HOLDER, Governor Weight

PIN, Governor Weight

GASKET, Case Cover

Honda GX340K1QA2 Crankshaft Assy

WEIGHT, Balancer

13310ZE3601

13351ZE3010

90756ZE2600 KEY 961006207000

Honda GX340K1QA2 Cylinder Barrel Assy

USE from Engine

SHAFT, Governor ARM

BOLT, Drain Plug

NUT, Flange 10MM

Honda GX340K1QA2 Cylinder Head Assy

CLIP, Valve Guide

GASKET, Cylinder Head

COVER, Head

TUBE, Breather

Honda GX340K1QA2 FAN Cover Assy

CLIP, Wire Harness

CLIP, Tube

COVER, FAN *R8* Bright RED

Shroud

Honda GX340K1QA2 Flywheel Assy

FAN, Cooling

Flywheel

Honda GX340K1QA2 Fuel Tank Assy

RUBBER, Supporter 107MM

JOINT, Fuel Tank

Tank Fuel *T34* Simpson Blue

GASKET, Fuel Filler CAP

Honda GX340K1QA2 Ignition Coil Assy

GROMMET, Wire

Coil ASSEMBLY, Ignition

WIRE, Stop Switch 430MM

Honda GX340K1QA2 Carburetor Assy

Gasket SET

Valve SET, Float

Float SET

Includes Items W/%

Honda GX340K1QA2 Carburetor Assy

25 + 9430520122

Honda GX340K1QA2 Muffler Assy

Muffler

PROTECTOR, Muffler

PROTECTOR, EX. Pipe

PIPE, EX

Honda GX340K1QA2 Recoil Starter Assy

PULLEY, Recoil Starter

RATCHET, Starter

SPRING, Friction

SPRING, Starter Return

No ART Work

Honda GX340K1QA2 Control Assy

ARM, Governor

ROD, Governor

SPRING, Governor

SPRING, Throttle Return

Honda GX340K1QA2 Labels Assy

Emblem

LABEL, Caution

MARK, Choke External

MARK, OIL Alert E

Honda GX390K1QA2- AIR Cleaner Assy

Collar B, AIR Cleaner Includes Items W

WINGNUT, Tool BOX Setting

17231ZE3W01

90009ZE2003

Honda GX390K1QA2- Camshaft Assy

VALVE, Intake

VALVE, Exhaust

Honda GX390K1QA2- Piston Assy

Ring SET, Piston STD

Ring SET, Piston OS 0.25, OPT

Ring SET, Piston OS 0.50, OPT

Piston Standard

Honda GX390K1QA2- Crankcase Cover Assy

Includes Items W/ #

Honda GX390K1QA2- Crankshaft Assy

90745ZE2600 KEY 91001ZF6003

13310ZF6W10

BEARING, Radial Ball 6207S

Honda GX390K1QA2- Cylinder Barrel Assy

91353671003

91203952771

3415ZH7003

Honda GX390K1QA2- Cylinder Head Assy

GUIDE, Valve OS Optional

GUIDE, EX. Valve OS Optional

GASKET, Cylinder Head Cover

Spark Plug BPR6ES NGK

Honda GX390K1QA2- FAN Cover Assy

19610ZE3010ZB

COVER, FAN *NH1*, Black

Honda GX390K1QA2- Flywheel Assy

PULLEY, Starter Screen Grid

Honda GX390K1QA2- Fuel Tank Assy

RUBBER, Supporter 107 MM

17510ZE3010ZB

TANK, Fuel *NH1* Black

91353671003 Ring 13.5X1.5 Arai 9405008000

Honda GX390K1QA2- Ignition Coil Assy

30500ZF6W01

Honda GX390K1QA2- Carburetor Assy

PLATE, Lever Setting

Screw SET, Drain Includes Items W/#

Screw SET B Includes Items W/#

JET, Main #92

Honda GX390K1QA2- Muffler Assy

PROTECTOR, Exhaust Pipe

PIPE, Exhaust

Honda GX390K1QA2- Recoil Starter Assy

28400ZE3W01ZB

28410ZE3W01ZB

28462ZV7003

90008ZE2003

Honda GX390K1QA2- Control Assy

BASE, Control

NUT, SELF-LOCK 6MM

Honda GX390K1QA2- Gasket KIT Assy

GASKET, Exhaust Pipe

GASKET, Insulator

Gasket KIT

Honda GX390K1QA2- Labels Assy

87530ZF6W10

87521ZF6W01

87576ZH7W00

Terms and Conditions of Sale Parts

Page

HERE’S HOW to GET Help