MC3PEA, MC3PBA (B&S), MC3SBA (B&S), MC3SEA specifications

The Multiquip MC3 series is a line of high-performance concrete power trowels, especially designed to improve surface finishing, enhancing both efficiency and quality in various construction projects. The MC3SEA, MC3SBA (B&S), MC3PBA (B&S), and MC3PEA models offer advanced technologies and features that cater to the needs of different applications.One of the standout features of the MC3 series is its robust construction. Each model is built with a heavy-duty steel frame, ensuring durability and longevity in demanding environments. The trowels are engineered to withstand rigorous use while providing excellent stability during operation, which is critical for achieving a smooth finish on concrete surfaces.

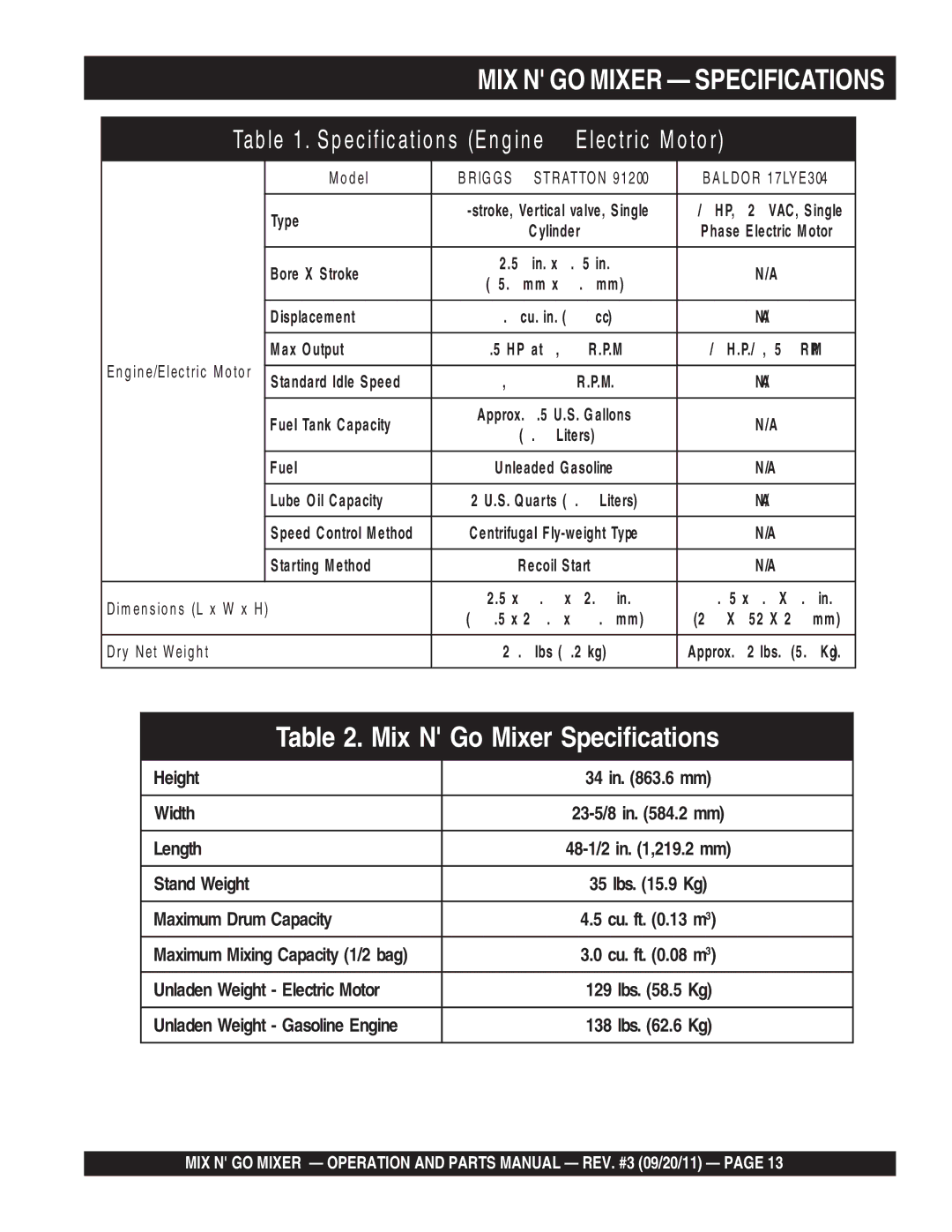

Powering these machines are reliable engine options, with the B&S (Briggs & Stratton) engines integrated into the MC3SBA and MC3PBA models. These engines are known for their fuel efficiency and ease of maintenance, making them an optimal choice for contractors seeking reliable performance. The MC3SEA and MC3PEA models offer alternative engine configurations tailored for specific applications, providing contractors with choices that best suit their work demands.

The torque capabilities of the MC3 series are impressive, allowing for effective power transfer to the trowel blades. This results in a thorough finishing process, enhancing the evenness of concrete surfaces. The trowels come with various blade options, including both standard and extended blades, enabling operators to customize their equipment based on job requirements.

The ergonomics of the MC3 series have been designed with user comfort in mind. Equipped with padded handles and adjustable operating positions, operators can work for extended periods without experiencing fatigue. The intuitive control layout enhances maneuverability, allowing for precise handling in tight spaces.

Another key characteristic of the MC3 series is its easy maintenance. With accessible engine compartments and straightforward service points, routine maintenance tasks can be performed with minimal downtime, ensuring that contractors can keep their projects on schedule.

In summary, the Multiquip MC3SEA, MC3SBA (B&S), MC3PBA (B&S), and MC3PEA power trowels represent a blend of power, durability, and user-friendliness. Their robust construction, versatile engine options, ergonomic design, and easy maintenance make them ideal choices for concrete finishing tasks, providing contractors with the reliability and performance needed to achieve high-quality results on the job site.