MDR-9DYE—MAINTENANCE

HYDRAULIC AIR EXTRACTION

1.After filling hydraulic oil tank with oil, loosen the oil hose joint and check that oil is enough to reach the oil suction and outlet ports in the hydraulic transmission. Tighten the hose joint securely after checking.

2.Loosen the charge relief valve located on the front side of the hydraulic transmission (Figure 33).

Figure 33. Loosening Charge Relief Valve

3.Check that oil flows out from the valve hole.

4.Replace the charge relief valve tightly.

5.With the travel and vibrator levers in neutral position, start the engine and idle at low speed for 3 to 5 minutes.

6.Check the forward and reverse rotation of the output shaft by moving the travel lever slowly to its forward and reverse positions.

7.Check the oil level gauge and make sure that there are no air bubbles mixed in the oil. After checking, operate the roller slowly at first then at full speed.

8.When oil level in the tank is low, replenish oil up to the specified level, and screw the cap securely with a wrench.

9.If bubbles remain in the oil or foam is found, air is being sucked through the suction side and should be checked.

NEUTRAL POSITION ADJUSTMENT

Once the travel lever has been set to neutral position with the engine running, the hydraulic brake is operating and the roller should not move. If the roller inches forward or backwards with the lever in the neutral position,

1.Stop the engine and set the travel lever in the neutral position.

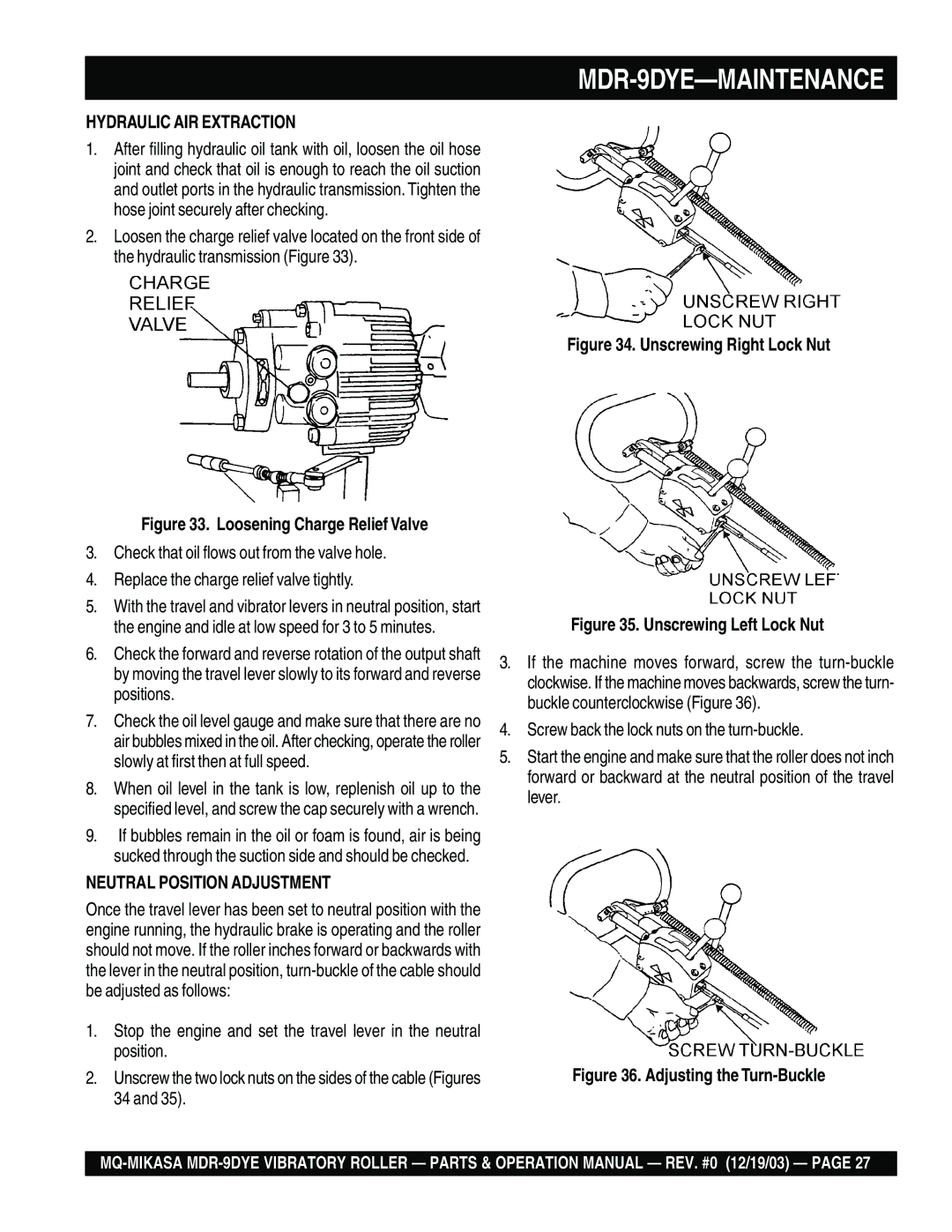

2.Unscrew the two lock nuts on the sides of the cable (Figures 34 and 35).

Figure 34. Unscrewing Right Lock Nut

Figure 35. Unscrewing Left Lock Nut

3.If the machine moves forward, screw the

4.Screw back the lock nuts on the

5.Start the engine and make sure that the roller does not inch forward or backward at the neutral position of the travel lever.