Pre-inspection (Engine/mixer)

Before Starting

1.Read safety instructions at the beginning of manual.

2.Clean the mixer, removing dirt and dust, particularly the engine cooling air inlet, carburetor and air cleaner.

3.Check the air filter for dirt and dust. If air filter is dirty, replace air filter with a new one as required.

4.Check carburetor for external dirt and dust. Clean with dry compressed air.

5.Check fastening nuts and bolts for tightness.

Engine Oil Check

1.To check the engine oil level, place the mixer on secure level ground with the engine stopped.

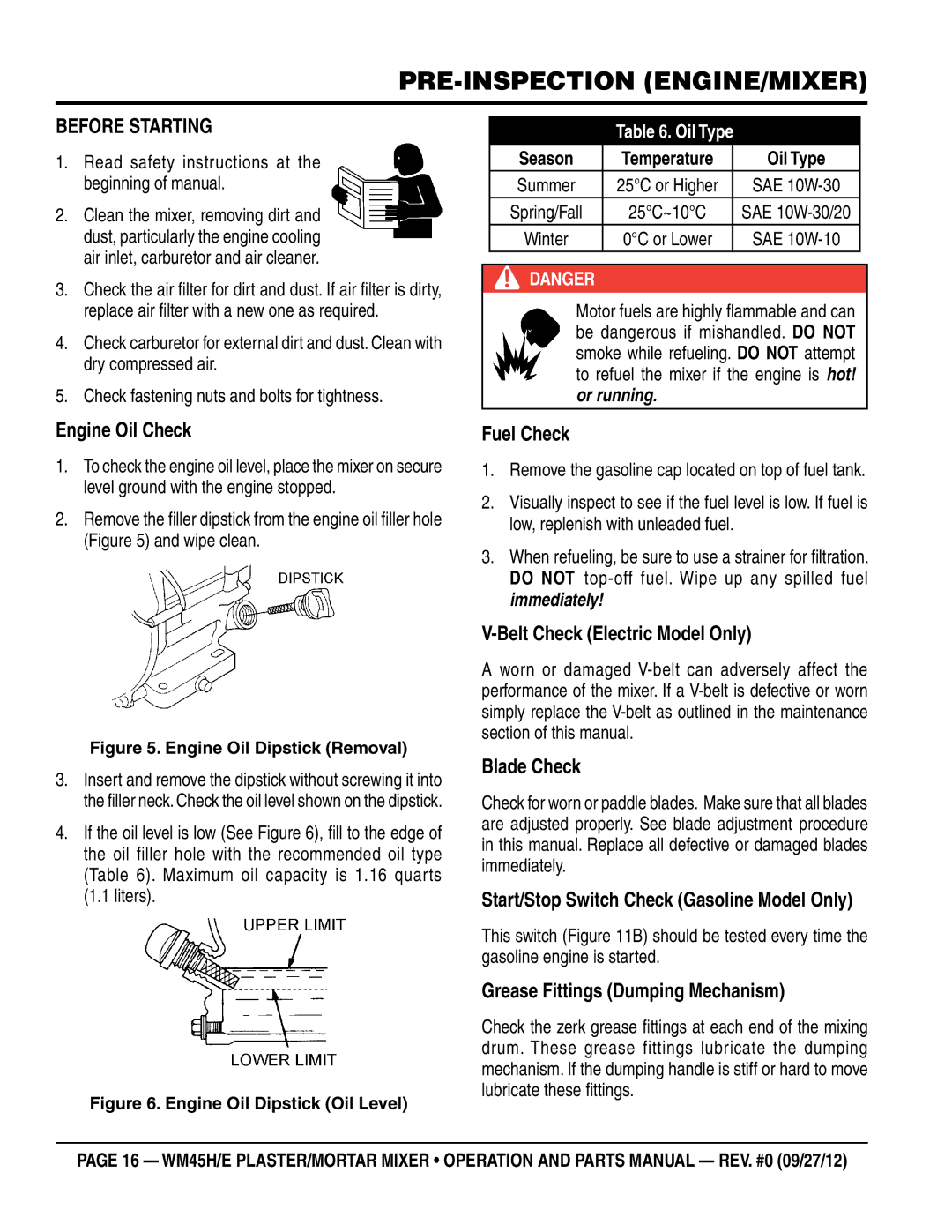

2.Remove the filler dipstick from the engine oil filler hole (Figure 5) and wipe clean.

Figure 5. Engine Oil Dipstick (Removal)

3.Insert and remove the dipstick without screwing it into the filler neck. Check the oil level shown on the dipstick.

4.If the oil level is low (See Figure 6), fill to the edge of the oil filler hole with the recommended oil type (Table 6). Maximum oil capacity is 1.16 quarts (1.1 liters).

Figure 6. Engine Oil Dipstick (Oil Level)

Table 6. Oil Type

Season | Temperature | Oil Type |

Summer | 25°C or Higher | SAE |

Spring/Fall | 25°C~10°C | SAE |

Winter | 0°C or Lower | SAE |

DANGER

Motor fuels are highly flammable and can be dangerous if mishandled. DO NOT smoke while refueling. DO NOT attempt to refuel the mixer if the engine is hot! or running.

Fuel Check

1.Remove the gasoline cap located on top of fuel tank.

2.Visually inspect to see if the fuel level is low. If fuel is low, replenish with unleaded fuel.

3.When refueling, be sure to use a strainer for filtration. DO NOT

V-Belt Check (Electric Model Only)

A worn or damaged

Blade Check

Check for worn or paddle blades. Make sure that all blades are adjusted properly. See blade adjustment procedure in this manual. Replace all defective or damaged blades immediately.

Start/Stop Switch Check (Gasoline Model Only)

This switch (Figure 11B) should be tested every time the gasoline engine is started.

Grease Fittings (Dumping Mechanism)

Check the zerk grease fittings at each end of the mixing drum. These grease fittings lubricate the dumping mechanism. If the dumping handle is stiff or hard to move lubricate these fittings.

page 16 — WM45H/E PLASTER/MORTAR MIXER • operation and parts manual — rev. #0 (09/27/12)