MVH-304DSB specifications

The Multiquip MVH-304DSB is a versatile and robust dual drum vibratory roller, designed to meet the demands of various construction and landscaping projects. This machine is renowned for its efficiency in compacting asphalt, soil, and gravel, making it an essential tool for contractors and engineers alike.One of the standout features of the MVH-304DSB is its high-performance diesel engine, which provides ample power while ensuring fuel efficiency. The engine is not only dependable but also meets stringent emission standards, showcasing Multiquip’s commitment to environmentally friendly solutions. With a rated output, the machine can easily handle even the most demanding compaction tasks.

The design of the MVH-304DSB is characterized by its dual drum configuration, which enhances stability and control during operation. Each drum is independently driven, offering excellent maneuverability in tight spaces and around obstacles. The rollers are constructed from high-quality steel, ensuring durability and long operational life. Additionally, the machine features a smooth surface roller design, which provides even compaction without damaging the material.

The MVH-304DSB is equipped with advanced vibratory technology that optimizes compaction performance. The adjustable vibration frequency allows the operator to fine-tune the compaction for different materials, ensuring maximum efficiency. This feature is essential for achieving the desired compaction density and ultimately contributes to the longevity and stability of the surface being compacted.

Operator comfort and safety are priorities in the design of the MVH-304DSB. The machine boasts a spacious operator’s platform with ergonomic controls that enhance productivity. Visibility is also a key consideration, with strategically placed windows and low-profile design that ensure the operator has an unobstructed view of the work area.

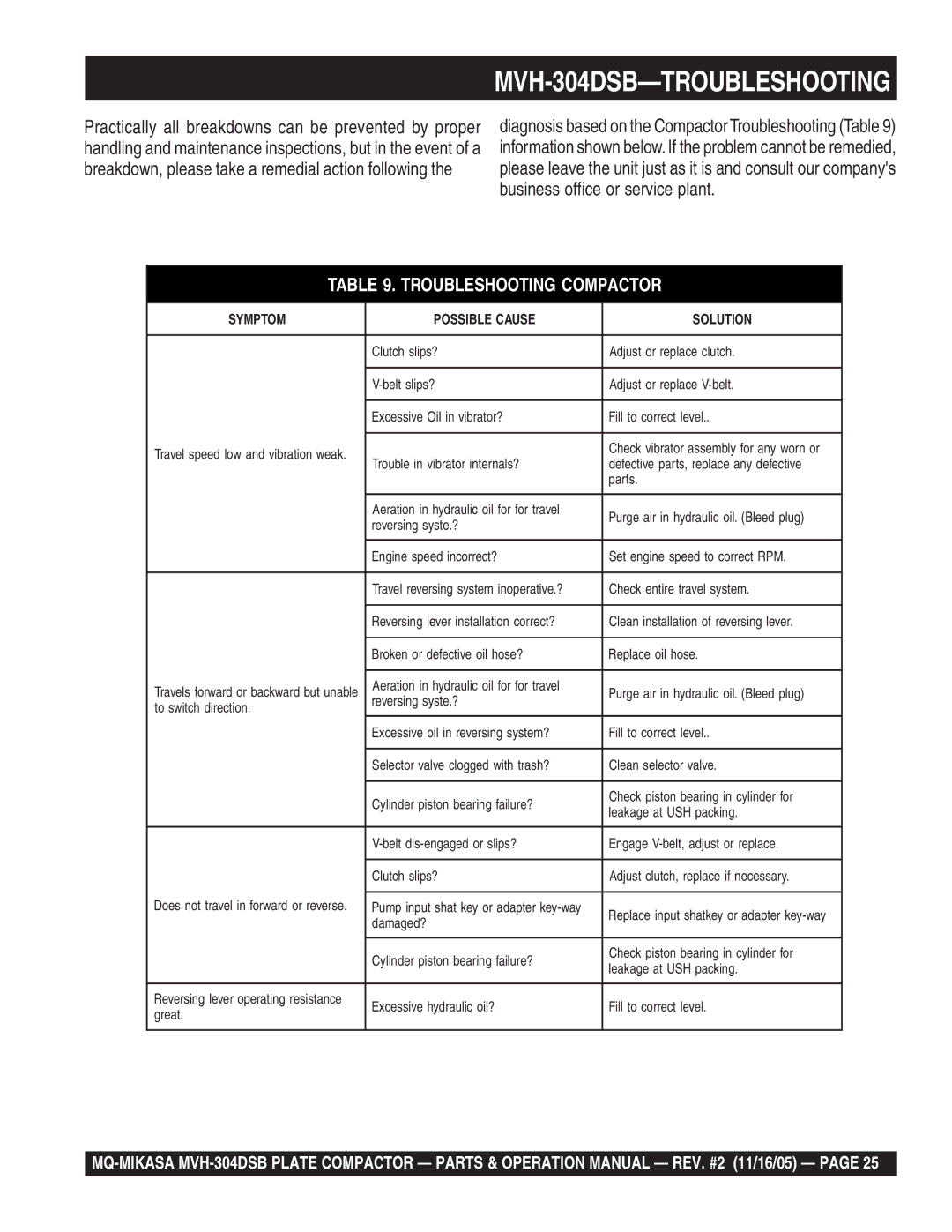

In terms of maintenance, the MVH-304DSB is designed for easy access to critical components, simplifying routine checks and servicing. This not only reduces downtime but also extends the lifespan of the roller.

Overall, the Multiquip MVH-304DSB stands out in the marketplace for its combination of power, efficiency, and user-friendly features, making it an excellent choice for those looking to enhance their compaction capabilities on site. Its innovative technologies and robust construction ensure that it remains a reliable workhorse for any construction project.