maintenance

Refer to your engine manual for specific details to perform this operation.

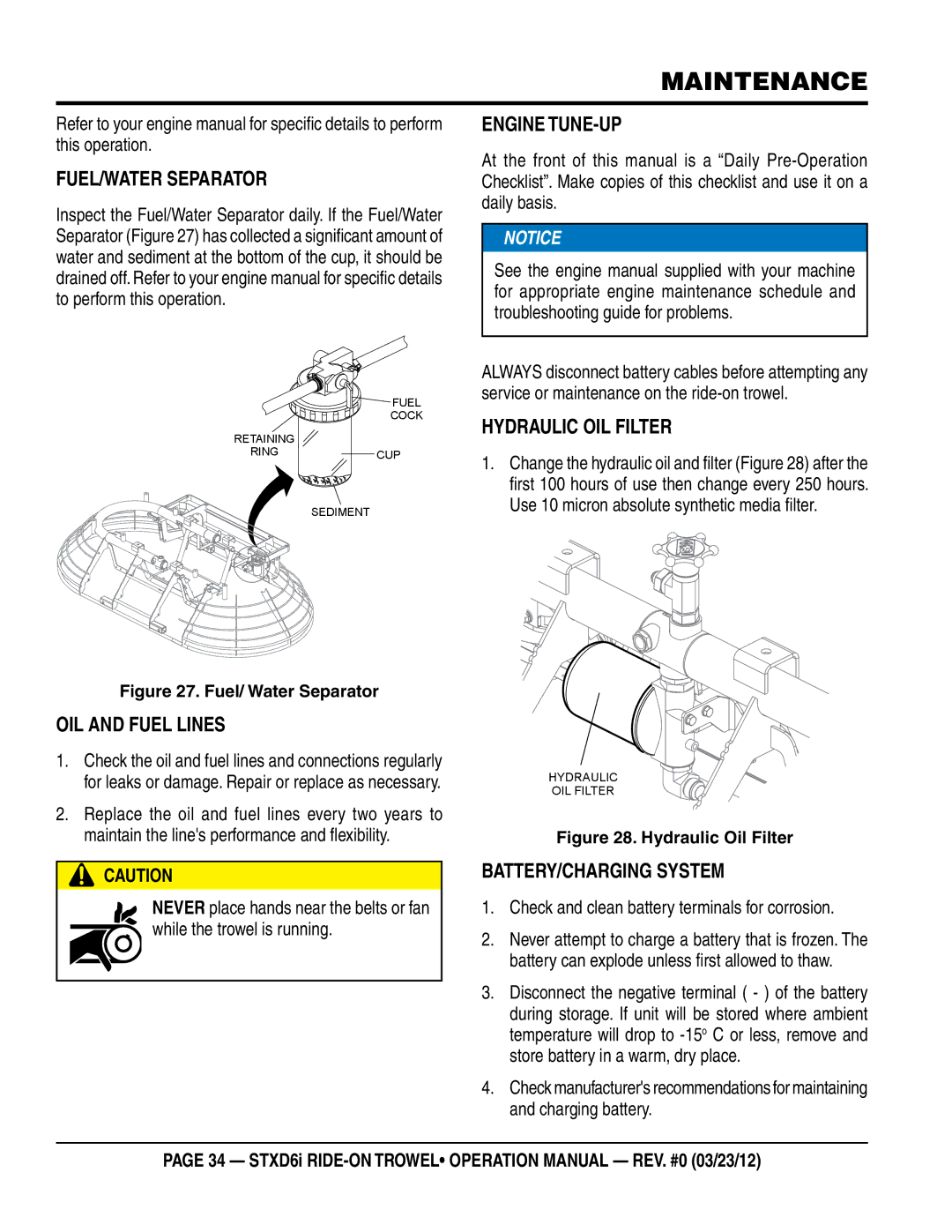

fuel/Water Separator

Inspect the Fuel/Water Separator daily. If the Fuel/Water Separator (Figure 27) has collected a significant amount of water and sediment at the bottom of the cup, it should be drained off. Refer to your engine manual for specific details to perform this operation.

| FUEL |

| COCK |

RETAINING |

|

RING | CUP |

| SEDIMENT |

Figure 27. Fuel/ Water Separator

Oil And Fuel Lines

1.Check the oil and fuel lines and connections regularly for leaks or damage. Repair or replace as necessary.

2.Replace the oil and fuel lines every two years to maintain the line's performance and flexibility.

![]() CAUTION

CAUTION

NEVER place hands near the belts or fan while the trowel is running.

Engine Tune-Up

At the front of this manual is a “Daily

![]() NOTICE

NOTICE

See the engine manual supplied with your machine for appropriate engine maintenance schedule and troubleshooting guide for problems.

ALWAYS disconnect battery cables before attempting any service or maintenance on the

hydraulic oil filter

1.Change the hydraulic oil and filter (Figure 28) after the first 100 hours of use then change every 250 hours. Use 10 micron absolute synthetic media filter.

HYDRAULIC

OIL FILTER

Figure 28. Hydraulic Oil Filter

Battery/Charging System

1.Check and clean battery terminals for corrosion.

2.Never attempt to charge a battery that is frozen. The battery can explode unless first allowed to thaw.

3.Disconnect the negative terminal ( - ) of the battery during storage. If unit will be stored where ambient temperature will drop to

4.Check manufacturer's recommendations for maintaining and charging battery.

page 34 — stxd6i