DANGERBEFORE TOWING

BALL HITCH COUPLER

1.Check vehicle hitch, ball, and coupler for signs of wear or damage. Replace any parts that are worn or damaged before towing.

2.Use only the 2" ball diameter as indicated on your coupler. Use of any other ball diameter will create an extremely dangerous condition which can result in separation of the coupler and ball or ball failure.

3.Be sure the coupler is secured to the hitch ball and the lock lever is down tight and locked.

Recheck tightness again after towing about 50 miles.

4.Check that trailer safety chains are properly connected.

RECOMMENDED MAINTENANCE

1.Smear ball socket and clamp face with chassis grease. Periodically oil pivot points and solutions surfaces of coupler with SAE 30 wt. motor oil.

2.When parking or storing your trailer. Keep the coupler off the ground so dirt will not build up in the ball socket.

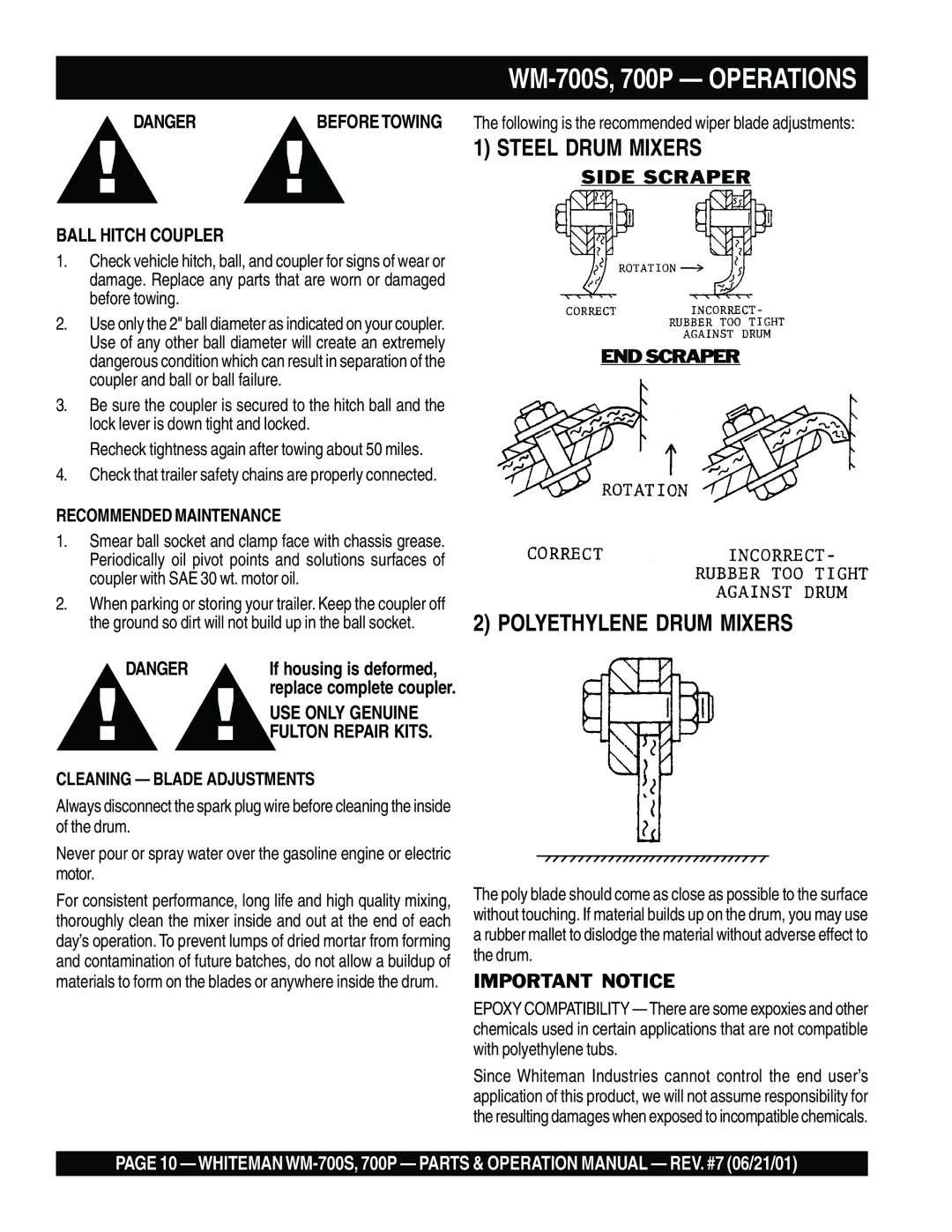

The following is the recommended wiper blade adjustments:

1) STEEL DRUM MIXERS

ENDSCRAPER

2) POLYETHYLENE DRUM MIXERS

DANGER | If housing is deformed, |

| replace complete coupler. |

| USE ONLY GENUINE |

| FULTON REPAIR KITS. |

CLEANING — BLADE ADJUSTMENTS

Always disconnect the spark plug wire before cleaning the inside of the drum.

Never pour or spray water over the gasoline engine or electric motor.

For consistent performance, long life and high quality mixing, thoroughly clean the mixer inside and out at the end of each day’s operation. To prevent lumps of dried mortar from forming and contamination of future batches, do not allow a buildup of materials to form on the blades or anywhere inside the drum.

The poly blade should come as close as possible to the surface without touching. If material builds up on the drum, you may use a rubber mallet to dislodge the material without adverse effect to the drum.

IMPORTANT NOTICE

EPOXY COMPATIBILITY — There are some expoxies and other chemicals used in certain applications that are not compatible with polyethylene tubs.

Since Whiteman Industries cannot control the end user’s application of this product, we will not assume responsibility for the resulting damages when exposed to incompatible chemicals.

PAGE 10