67 | HEATER INSPECTION AND MAINTENANCE SCHEDULE |

|

|

|

| ||

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

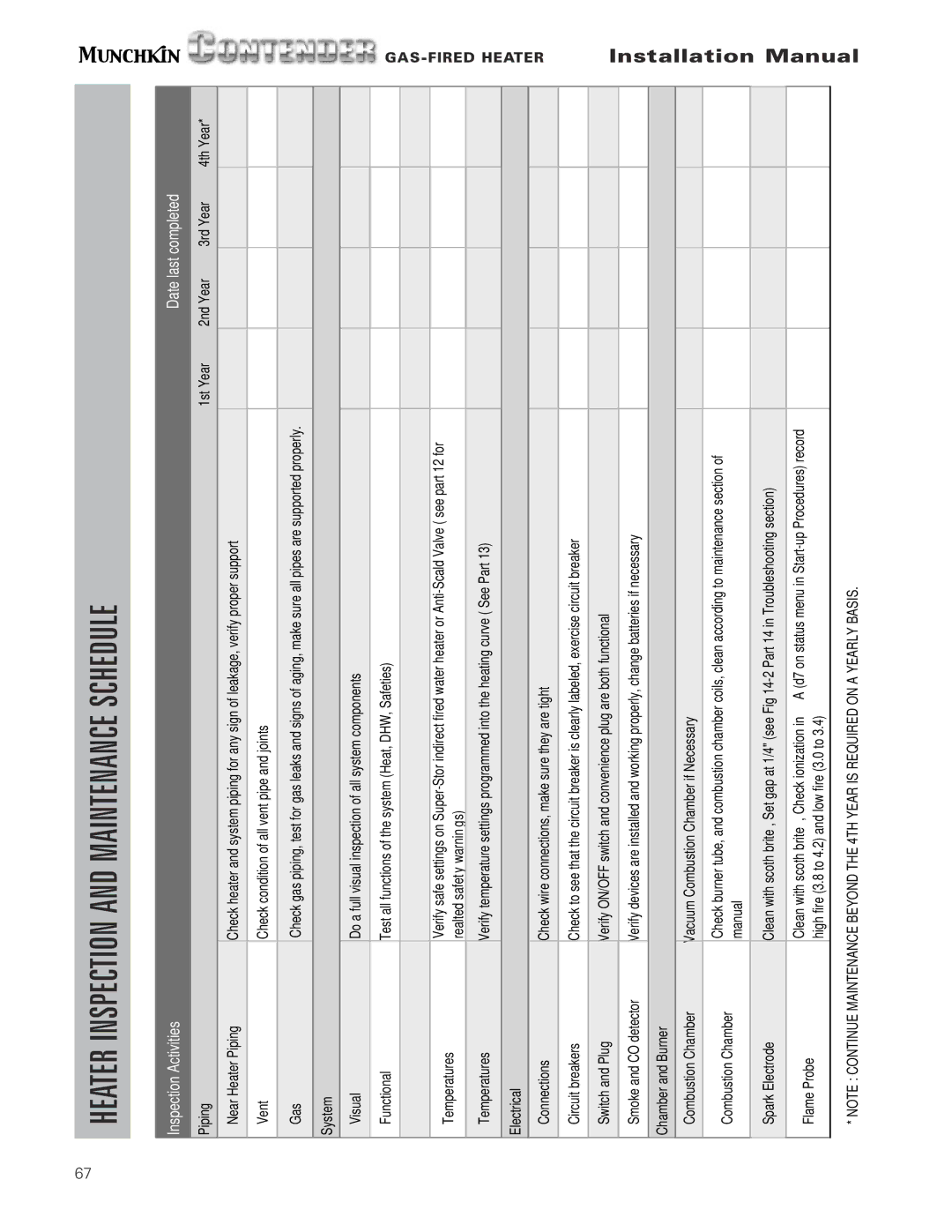

| Inspection Activities |

|

| Date last completed |

|

| |

|

|

|

|

|

|

|

|

| Piping |

| 1st Year | 2nd Year | 3rd Year | 4th Year* |

|

| Near Heater Piping | Check heater and system piping for any sign of leakage, verify proper support |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Vent | Check condition of all vent pipe and joints |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Gas | Check gas piping, test for gas leaks and signs of aging, make sure all pipes are supported properly. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| System |

|

|

|

|

|

|

| Visual | Do a full visual inspection of all system components |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Functional | Test all functions of the system (Heat, DHW, Safeties) |

|

|

|

| GAS- |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

| Temperatures | Verify safe settings on |

|

|

|

| FIRED |

|

|

|

|

|

| ||

| realted safety warnings) |

|

|

|

|

| |

|

|

|

|

|

|

| |

| Temperatures | Verify temperature settings programmed into the heating curve ( See Part 13) |

|

|

|

| HEATER |

|

|

|

|

|

|

| |

| Electrical |

|

|

|

|

| |

|

|

|

|

|

|

| |

| Connections | Check wire connections, make sure they are tight |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Circuit breakers | Check to see that the circuit breaker is clearly labeled, exercise circuit breaker |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Switch and Plug | Verify ON/OFF switch and convenience plug are both functional |

|

|

|

| Installation |

|

|

|

|

|

|

| |

| Smoke and CO detector | Verify devices are installed and working properly, change batteries if necessary |

|

|

|

| |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| Chamber and Burner |

|

|

|

|

|

|

| Combustion Chamber | Vacuum Combustion Chamber if Necessary |

|

|

|

|

|

| Combustion Chamber | Check burner tube, and combustion chamber coils, clean according to maintenance section of |

|

|

|

|

|

| manual |

|

|

|

|

| |

|

|

|

|

|

|

| |

| Spark Electrode | Clean with scoth brite , Set gap at 1/4" (see Fig |

|

|

|

| Manual |

|

|

|

|

|

|

| |

| Flame Probe | Clean with scoth brite , Check ionization in µA (d7 on status menu in |

|

|

|

| |

| high fire (3.8 to 4.2) and low fire (3.0 to 3.4) |

|

|

|

| ||

|

|

|

|

|

| ||

| * NOTE : CONTINUE MAINTENANCE BEYOND THE 4TH YEAR IS REQUIRED ON A YEARLY BASIS. |

|

|

| |||