465609x24A specifications

Murray 465609x24A is a versatile and robust equipment designed for a variety of applications, particularly in the fields of agriculture and industrial use. Engineered for durability and efficiency, this model is built to withstand rigorous conditions while providing high performance.One of the standout features of the Murray 465609x24A is its powerful engine. It is equipped with a state-of-the-art propulsion system that ensures maximum output with minimal fuel consumption. The engine's advanced technology allows for smooth operation, whether it's powering through tough terrains or handling heavy loads. This makes it ideal for users who demand reliability in challenging environments.

In addition to its powerful engine, the 465609x24A incorporates advanced safety features which are paramount for both operator protection and equipment longevity. An integrated sensor system continuously monitors the machine’s performance, automatically adjusting parameters to prevent overheating and maintain optimal working conditions. This technology not only enhances safety but also extends the lifespan of the equipment.

The design of the Murray 465609x24A is fundamentally user-centric. It features an ergonomic layout that allows for ease of operation. The controls are intuitively placed, enabling operators to manage tasks efficiently without unnecessary complication. The spacious cabin allows for extended use without compromising comfort, which is essential during long workdays.

Furthermore, the 465609x24A includes a versatile attachment system, accommodating a wide range of tools and implements. This adaptability enhances its functionality, allowing users to tailor the machine according to specific tasks—whether it’s plowing, lifting, or transporting materials.

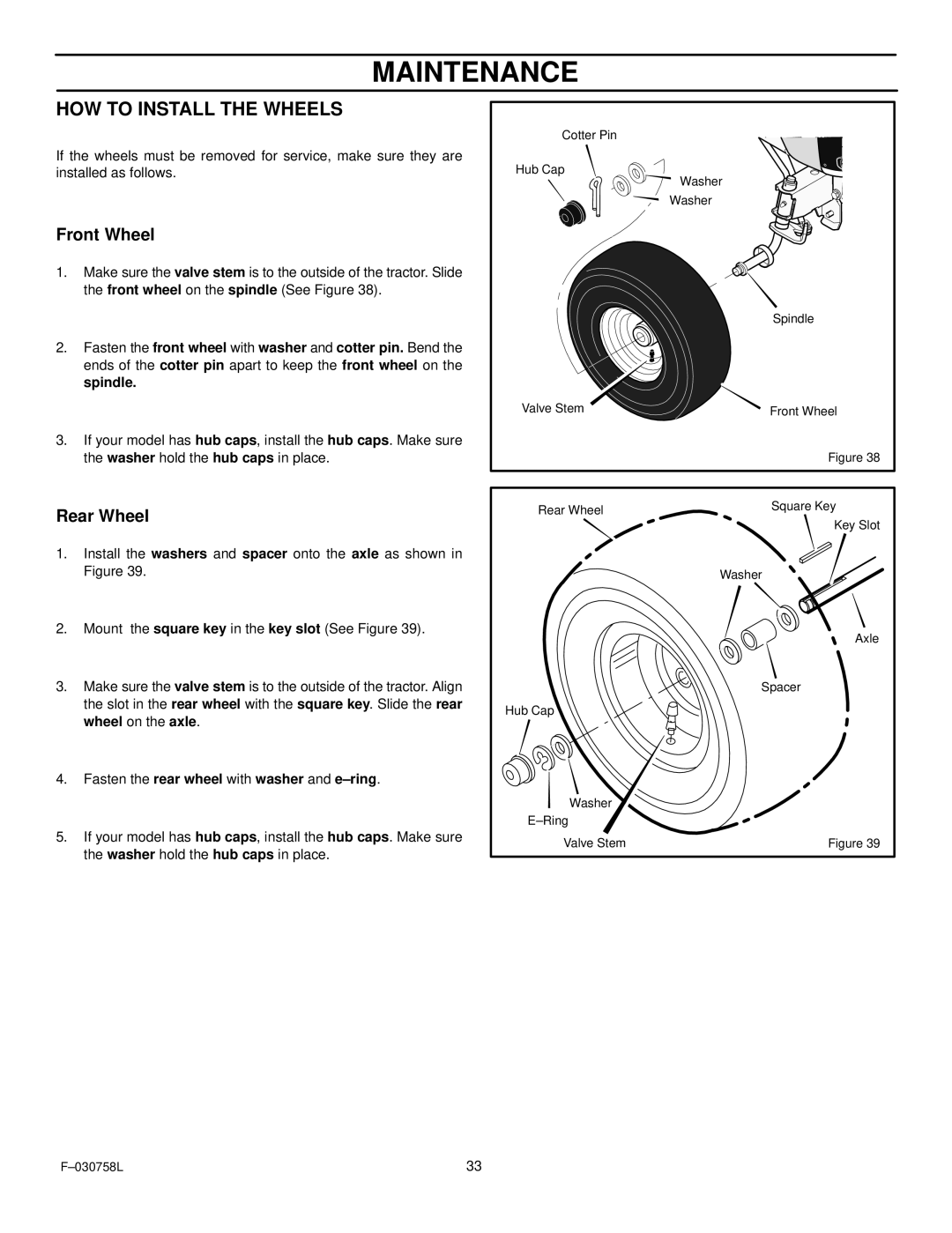

Maintenance is simplified with the Murray 465609x24A. The design includes easy access points for routine checks, making it straightforward for operators to conduct maintenance tasks. This emphasis on serviceability ensures that the machine remains in peak operational condition, reducing downtime and increasing productivity.

In conclusion, the Murray 465609x24A stands out as a reliable, efficient, and adaptable piece of machinery. With its powerful engine, robust safety features, user-friendly design, and easy maintenance, it is a formidable choice for those in need of a dependable workhorse in demanding environments. The combination of these characteristics makes the Murray 465609x24A a leading choice in its category, appealing to both professional and industrial users alike.