27

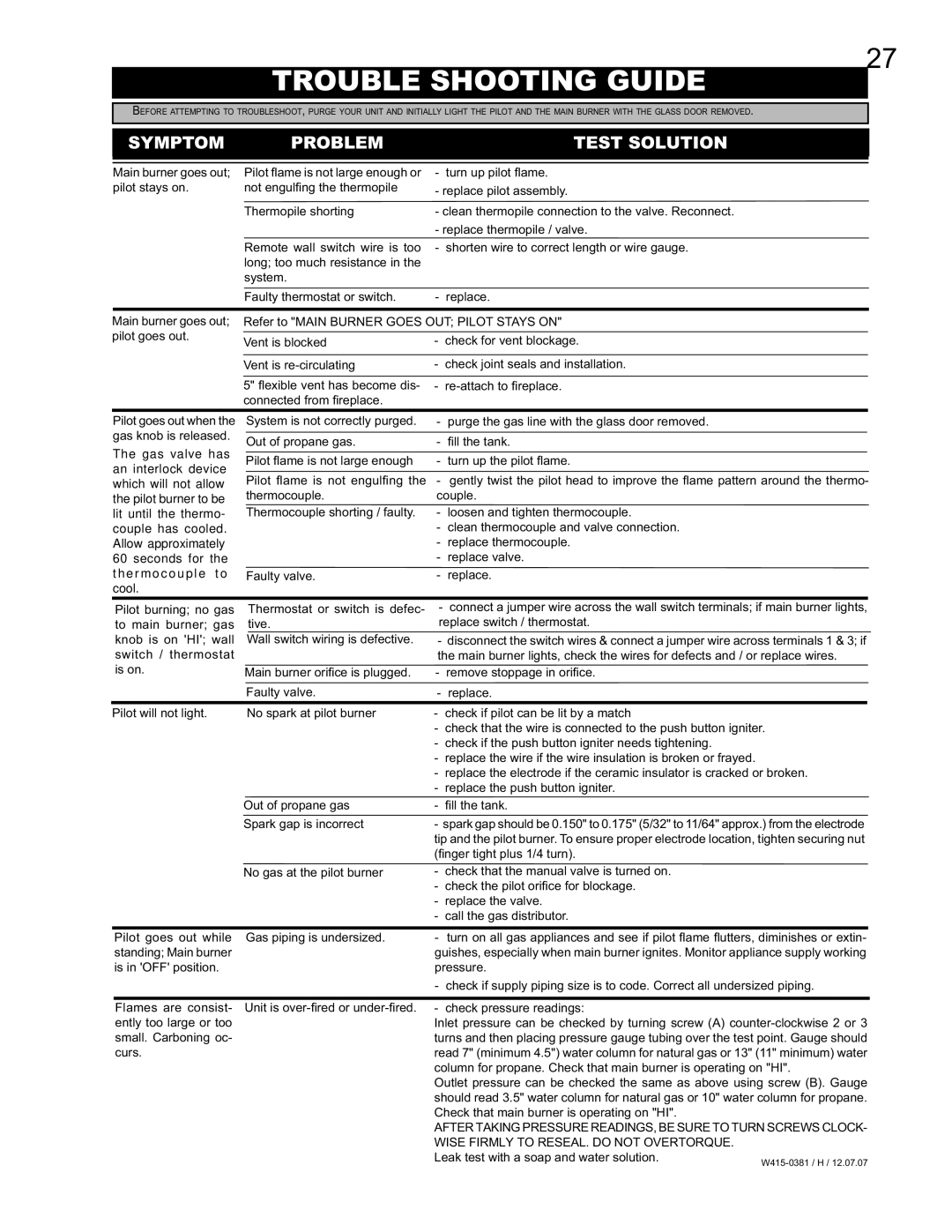

TROUBLE SHOOTING GUIDE

BEFORE ATTEMPTING TO TROUBLESHOOT, PURGE YOUR UNIT AND INITIALLY LIGHT THE PILOT AND THE MAIN BURNER WITH THE GLASS DOOR REMOVED.

| SYMPTOM |

|

| PROBLEM |

| TEST SOLUTION | |||

|

|

|

| ||||||

| Main burner goes out; Pilot fl ame is not large enough or | - | turn up pilot fl ame. | ||||||

| pilot stays on. | not engulfi ng the thermopile | - replace pilot assembly. | ||||||

|

| Thermopile shorting | - clean thermopile connection to the valve. Reconnect. | ||||||

|

|

|

|

| - replace thermopile / valve. | ||||

|

| Remote wall switch wire is too | - | shorten wire to correct length or wire gauge. | |||||

|

| long; too much resistance in the |

|

|

|

| |||

|

| system. |

|

|

|

| |||

|

| Faulty thermostat or switch. | - | replace. | |||||

|

|

|

|

| |||||

Main burner goes out; Refer to "MAIN BURNER GOES OUT; PILOT STAYS ON" | |||||||||

pilot goes out. |

|

|

|

|

|

|

| ||

Vent is blocked | - | check for vent blockage. | |||||||

|

| ||||||||

|

|

|

|

|

| ||||

|

| Vent is | - | check joint seals and installation. | |||||

|

|

|

|

|

| ||||

|

| 5" fl exible vent has become dis- | - | ||||||

|

| connected from fi replace. |

|

|

|

| |||

| Pilot goes out when the |

| System is not correctly purged. | - | purge the gas line with the glass door removed. | ||||

| gas knob is released. |

|

|

|

|

|

| ||

|

| Out of propane gas. | - | fi ll the tank. | |||||

| The gas valve has |

|

|

|

|

| |||

|

| Pilot fl ame is not large enough | - | turn up the pilot fl ame. |

| ||||

| an interlock device |

| Pilot fl ame is not engulfi ng the | - gently twist the pilot head to improve the fl ame pattern around the thermo- | |||||

| which will not allow |

| |||||||

| the pilot burner to be |

| thermocouple. | couple. | |||||

| lit until the thermo- |

| Thermocouple shorting / faulty. | - | loosen and tighten thermocouple. | ||||

| couple has cooled. |

|

|

| - | clean thermocouple and valve connection. | |||

| Allow approximately |

|

|

| - | replace thermocouple. | |||

| 60 seconds for the |

|

|

| - | replace valve. | |||

| thermocouple to |

| Faulty valve. | - | replace. | ||||

| cool. |

|

|

|

|

|

|

| |

| Pilot burning; no gas |

|

| Thermostat or switch is defec- | - | connect a jumper wire across the wall switch terminals; if main burner lights, |

| ||

| to main burner; gas |

|

| tive. | replace switch / thermostat. | ||||

| knob is on 'HI'; wall |

|

| Wall switch wiring is defective. | - disconnect the switch wires & connect a jumper wire across terminals 1 & 3; if | ||||

| switch / thermostat |

|

|

| the main burner lights, check the wires for defects and / or replace wires. | ||||

| is on. | Main burner orifi ce is plugged. | - | remove stoppage in orifi ce. | |||||

|

|

| Faulty valve. | - | replace. | ||||

Pilot will not light. |

| No spark at pilot burner | - | check if pilot can be lit by a match | |||||

|

|

|

|

| - | check that the wire is connected to the push button igniter. | |||

|

|

|

|

| - | check if the push button igniter needs tightening. | |||

|

|

|

|

| - | replace the wire if the wire insulation is broken or frayed. | |||

|

|

|

|

| - | replace the electrode if the ceramic insulator is cracked or broken. | |||

|

|

|

|

| - | replace the push button igniter. | |||

|

| Out of propane gas | - | fi ll the tank. |

| ||||

|

| Spark gap is incorrect | - spark gap should be 0.150" to 0.175" (5/32" to 11/64" approx.) from the electrode | ||||||

|

|

|

|

| tip and the pilot burner. To ensure proper electrode location, tighten securing nut | ||||

|

|

|

|

| (fi nger tight plus 1/4 turn). | ||||

|

| No gas at the pilot burner | - | check that the manual valve is turned on. | |||||

|

|

|

|

| - | check the pilot orifi ce for blockage. | |||

|

|

|

|

| - | replace the valve. | |||

|

|

|

|

| - | call the gas distributor. | |||

|

|

|

|

|

|

| |||

| Pilot goes out while | Gas piping is undersized. | - turn on all gas appliances and see if pilot fl ame fl utters, diminishes or extin- | ||||||

| standing; Main burner |

|

|

| guishes, especially when main burner ignites. Monitor appliance supply working | ||||

| is in 'OFF' position. |

|

|

| pressure. | ||||

|

|

|

|

| - | check if supply piping size is to code. Correct all undersized piping. | |||

|

|

|

|

| |||||

| Flames are consist- | Unit is | - | check pressure readings: | |||||

| ently too large or too |

|

|

| Inlet pressure can be checked by turning screw (A) | ||||

| small. Carboning oc- |

|

|

| turns and then placing pressure gauge tubing over the test point. Gauge should | ||||

| curs. |

|

|

| read 7" (minimum 4.5") water column for natural gas or 13" (11" minimum) water | ||||

|

|

|

|

| column for propane. Check that main burner is operating on "HI". | ||||

|

|

|

|

| Outlet pressure can be checked the same as above using screw (B). Gauge | ||||

should read 3.5" water column for natural gas or 10" water column for propane. | |

Check that main burner is operating on "HI". |

|

AFTER TAKING PRESSURE READINGS, BE SURE TO TURN SCREWS CLOCK- | |

WISE FIRMLY TO RESEAL. DO NOT OVERTORQUE. |

|

Leak test with a soap and water solution. |

|

| |