14

INSTALLATION

WALL AND CEILING PROTECTION

HORIZONTAL VENT SECTIONS: A minimum clearance of 2" all around the vent pipe on all horizontal runs to combustibles is required. Use fi restop spacer

VERTICAL VENT SECTIONS: A minimum of 1" all around the vent pipe on all vertical runs to combustibles is required. Use fi restop spacer

HORIZONTAL INSTALLATION

This application occurs when venting |

|

throughanexteriorwall.Havingdetermined |

|

the air terminal location, cut and frame a |

|

hole in an exterior wall with a minimum |

|

opening as required. See Note above. | FIGURE 15 |

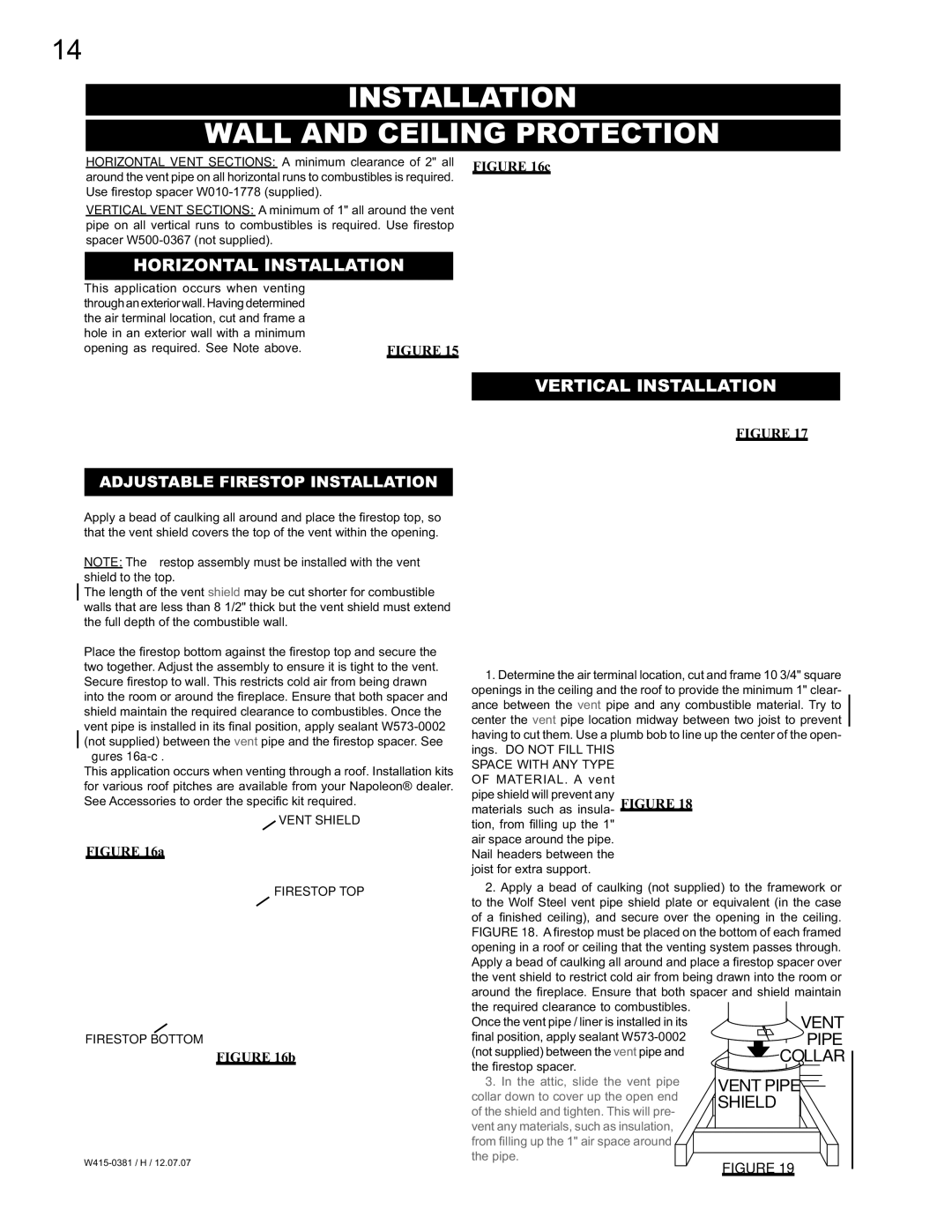

ADJUSTABLE FIRESTOP INSTALLATION

Apply a bead of caulking all around and place the fi restop top, so that the vent shield covers the top of the vent within the opening.

NOTE: The firestop assembly must be installed with the vent shield to the top.

The length of the vent shield may be cut shorter for combustible walls that are less than 8 1/2" thick but the vent shield must extend the full depth of the combustible wall.

Place the fi restop bottom against the fi restop top and secure the |

| |

two together. Adjust the assembly to ensure it is tight to the vent. | 1. Determine the air terminal location, cut and frame 10 3/4" square | |

Secure fi restop to wall. This restricts cold air from being drawn | ||

openings in the ceiling and the roof to provide the minimum 1" clear- | ||

into the room or around the fi replace. Ensure that both spacer and | ||

ance between the vent pipe and any combustible material. Try to | ||

shield maintain the required clearance to combustibles. Once the | ||

center the vent pipe location midway between two joist to prevent | ||

vent pipe is installed in its fi nal position, apply sealant | ||

having to cut them. Use a plumb bob to line up the center of the open- | ||

(not supplied) between the vent pipe and the fi restop spacer. See | ||

ings. DO NOT FILL THIS | ||

figures | ||

SPACE WITH ANY TYPE | ||

This application occurs when venting through a roof. Installation kits | ||

OF MATERIAL. A vent | ||

for various roof pitches are available from your Napoleon® dealer. | ||

pipe shield will prevent any | ||

See Accessories to order the specifi c kit required. | ||

materials such as insula- FIGURE 18 | ||

VENT SHIELD | ||

tion, from filling up the 1" | ||

FIGURE 16a | air space around the pipe. | |

Nail headers between the | ||

| joist for extra support. | |

FIRESTOP TOP | 2. Apply a bead of caulking (not supplied) to the framework or | |

to the Wolf Steel vent pipe shield plate or equivalent (in the case | ||

| ||

| of a fi nished ceiling), and secure over the opening in the ceiling. | |

| FIGURE 18. A fi restop must be placed on the bottom of each framed | |

| opening in a roof or ceiling that the venting system passes through. | |

| Apply a bead of caulking all around and place a fi restop spacer over | |

| the vent shield to restrict cold air from being drawn into the room or | |

| around the fi replace. Ensure that both spacer and shield maintain | |

| the required clearance to combustibles. | |

| Once the vent pipe / liner is installed in its | |

FIRESTOP BOTTOM | fi nal position, apply sealant | |

FIGURE 16b | (not supplied) between the vent pipe and | |

the fi restop spacer. | ||

| ||

| 3. In the attic, slide the vent pipe | |

| collar down to cover up the open end | |

| of the shield and tighten. This will pre- | |

| vent any materials, such as insulation, | |

| from filling up the 1" air space around | |

the pipe. | ||

|