7.1Cleaning of water inlet filter

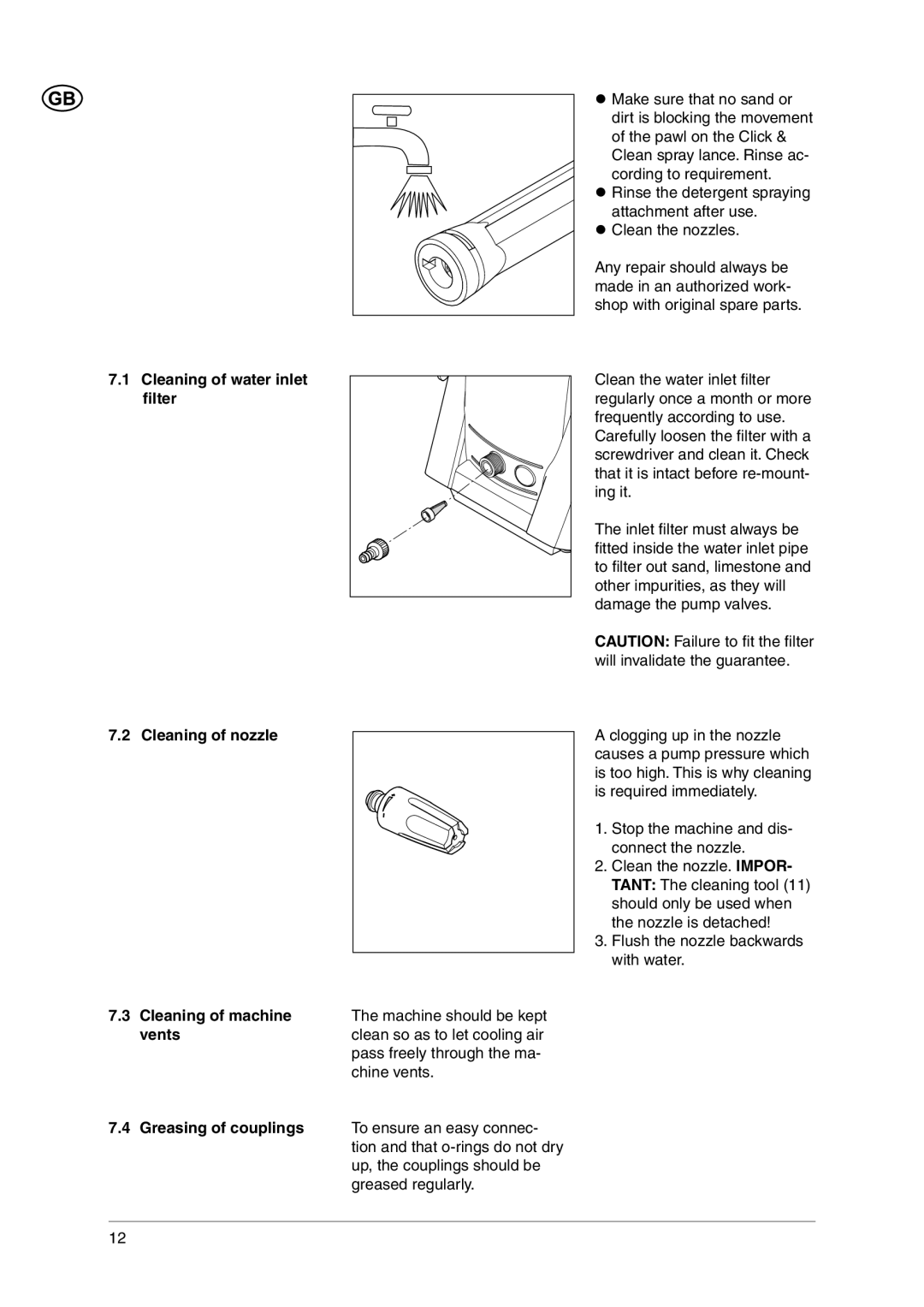

7.2 Cleaning of nozzle

7.3Cleaning of machine vents

7.4Greasing of couplings

The machine should be kept clean so as to let cooling air pass freely through the ma- chine vents.

To ensure an easy connec- tion and that

zMake sure that no sand or dirt is blocking the movement of the pawl on the Click & Clean spray lance. Rinse ac- cording to requirement.

zRinse the detergent spraying attachment after use.

zClean the nozzles.

Any repair should always be made in an authorized work- shop with original spare parts.

Clean the water inlet fi lter regularly once a month or more frequently according to use. Carefully loosen the fi lter with a screwdriver and clean it. Check that it is intact before

The inlet fi lter must always be

fitted inside the water inlet pipe to fi lter out sand, limestone and other impurities, as they will damage the pump valves.

CAUTION: Failure to fi t the fi lter will invalidate the guarantee.

A clogging up in the nozzle causes a pump pressure which is too high. This is why cleaning is required immediately.

1.Stop the machine and dis- connect the nozzle.

2.Clean the nozzle. IMPOR- TANT: The cleaning tool (11) should only be used when the nozzle is detached!

3.Flush the nozzle backwards with water.

12