valves operation. Green and yellow lights flash during this time.

If there is no call for humidity, the humidifier is standing by and green light flashes. When control loop is closed, the green light is steady on and the humidifier starts its operation. The controller waits 10 seconds before energizing the

During operation, the controller measures the rate at which water is converted to steam and thus the mineral content of water inside the cylinder. When this rate exceeds the design optimum, a drain of the cylinder takes place. The amount of water drained is just enough to keep the contained water at design levels.

During start up, when mineral content in the water is low, water will reach the top of the cylinder at which point the yellow indicator light will come on. This is normal operation with a fresh cylinder. After a period of time the water level will drop and the yellow light will turn off.

High water level in the cylinder also indicates that the cylinder is near the end of its service life as electrodes become coated with minerals. The yellow light coming on more often would be the first indication of approaching the end of the cylinder life.

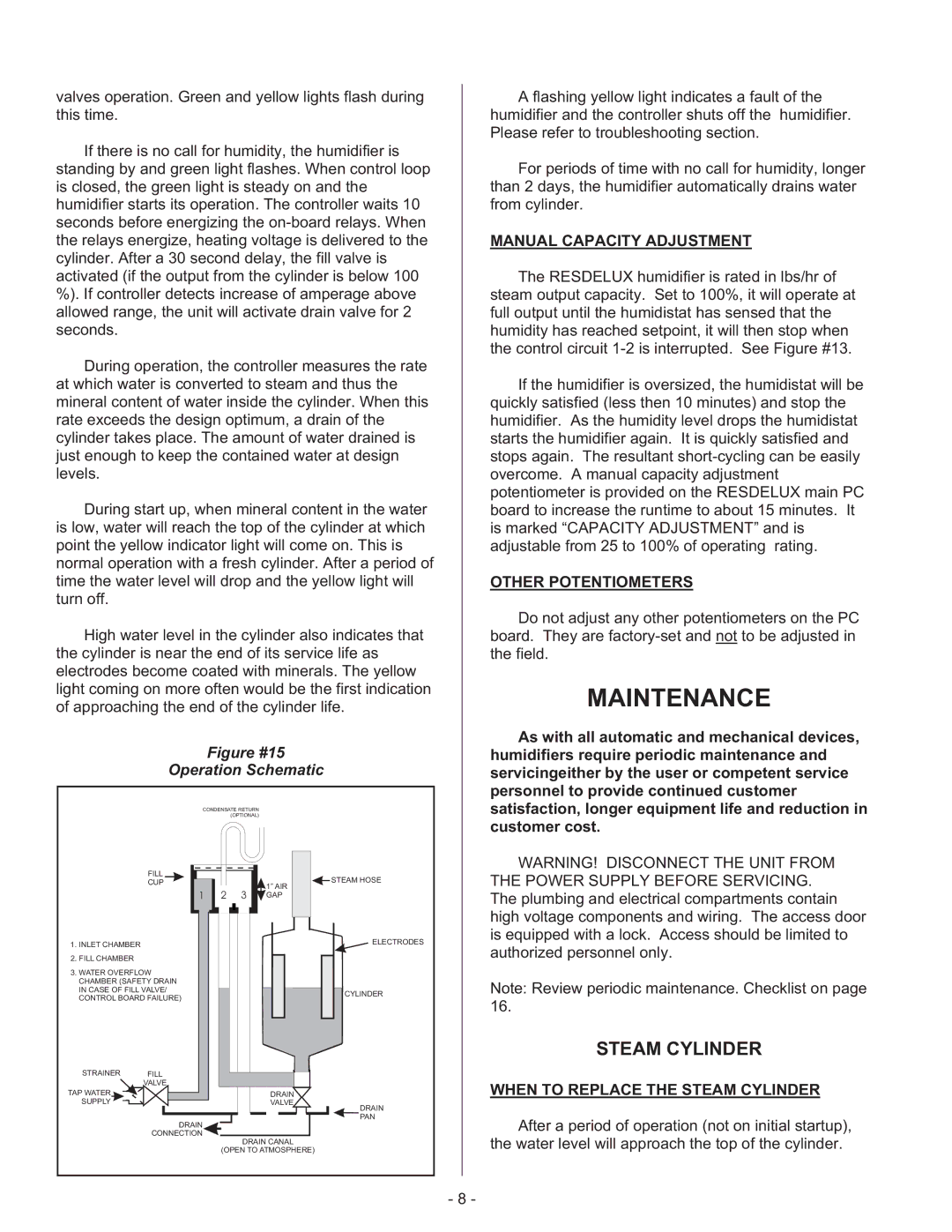

Figure #15

Operation Schematic

CONDENSATE RETURN (OPTIONAL)

A flashing yellow light indicates a fault of the

humidifier and the controller shuts off the humidifier. Please refer to troubleshooting section.

For periods of time with no call for humidity, longer than 2 days, the humidifier automatically drains water from cylinder.

MANUAL CAPACITY ADJUSTMENT

The RESDELUX humidifier is rated in lbs/hr of steam output capacity. Set to 100%, it will operate at full output until the humidistat has sensed that the humidity has reached setpoint, it will then stop when the control circuit

If the humidifier is oversized, the humidistat will be quickly satisfied (less then 10 minutes) and stop the humidifier. As the humidity level drops the humidistat starts the humidifier again. It is quickly satisfied and stops again. The resultant

OTHER POTENTIOMETERS

Do not adjust any other potentiometers on the PC board. They are

MAINTENANCE

As with all automatic and mechanical devices, humidifiers require periodic maintenance and servicingeither by the user or competent service personnel to provide continued customer satisfaction, longer equipment life and reduction in customer cost.

FILL

CUP

1.INLET CHAMBER

2.FILL CHAMBER

3.WATER OVERFLOW CHAMBER (SAFETY DRAIN IN CASE OF FILL VALVE/ CONTROL BOARD FAILURE)

STRAINER FILL VALVE

TAP WATER SUPPLY

|

|

| 1” AIR |

1 | 2 | 3 | GAP |

DRAIN |

VALVE |

![]() STEAM HOSE

STEAM HOSE

ELECTRODES

CYLINDER

DRAIN

PAN

WARNING! DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE SERVICING. The plumbing and electrical compartments contain high voltage components and wiring. The access door is equipped with a lock. Access should be limited to authorized personnel only.

Note: Review periodic maintenance. Checklist on page 16.

STEAM CYLINDER

WHEN TO REPLACE THE STEAM CYLINDER

DRAIN CONNECTION

DRAIN CANAL

(OPEN TO ATMOSPHERE)

After a period of operation (not on initial startup), the water level will approach the top of the cylinder.

- 8 -