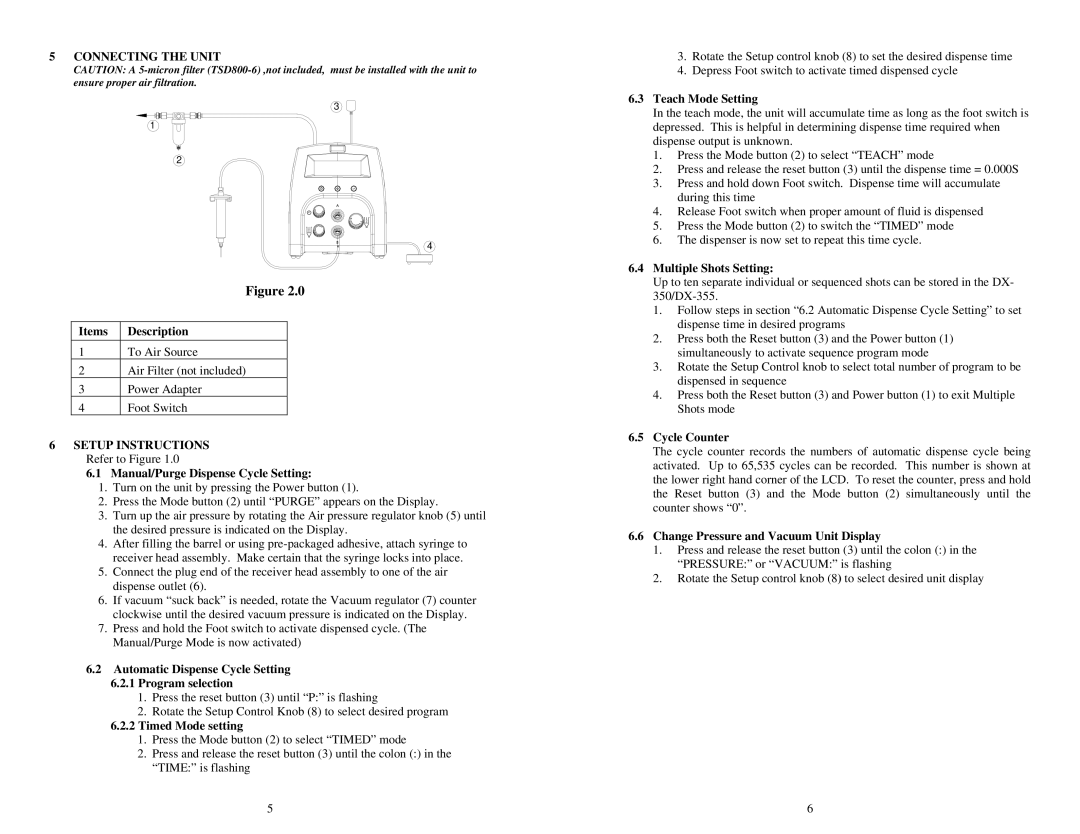

DX-350 / 355 specifications

The OK International DX-350 and DX-355 are state-of-the-art soldering and desoldering systems designed for modern electronic assembly and repair. These devices are ideal for both professional technicians and hobbyists, offering a blend of precision, efficiency, and user-friendly features.One of the standout characteristics of the DX-350 and DX-355 is their advanced temperature control technology. These systems utilize precise microprocessor control to maintain a consistent temperature, ensuring optimal soldering conditions while preventing damage to sensitive electronic components. The adjustable temperature ranges from 200°C to 450°C, providing the versatility needed for various soldering applications.

Another significant feature is the rapid heat-up time. Both models are designed to reach operational temperatures in a matter of seconds, allowing users to start their work without lengthy delays. This fast performance is coupled with excellent temperature recovery, ensuring that the soldering tip remains at the desired temperature even during extensive use.

The DX-350 and DX-355 are equipped with ergonomic soldering tools that prioritize user comfort. The lightweight design of the soldering iron reduces strain during extended use, while the soft grip handle provides a stable hold. Additionally, interchangeable tips with various shapes and sizes accommodate different soldering tasks, further enhancing the flexibility of these systems.

In terms of safety, both models feature an intelligent sleep mode that automatically reduces the temperature of the soldering iron after a period of inactivity. This not only conserves energy but also prolongs the lifespan of the soldering tips. Furthermore, the systems have built-in over-temperature protection to prevent overheating and potential damage to the equipment.

For added convenience, the DX-355 model includes a digital LCD display that provides real-time information about temperature settings and usage time. This feature allows users to track their work and make quick adjustments as necessary, ensuring optimal performance throughout the soldering process.

In summary, the OK International DX-350 and DX-355 are excellent choices for anyone seeking reliable, efficient, and user-friendly soldering solutions. Their advanced features, including precise temperature control, rapid heat-up, ergonomic design, safety measures, and additional digital functionalities, make them suitable for a wide range of electronic assembly and repair tasks. Whether you are a professional technician or an enthusiastic hobbyist, these systems will meet and exceed your soldering needs.