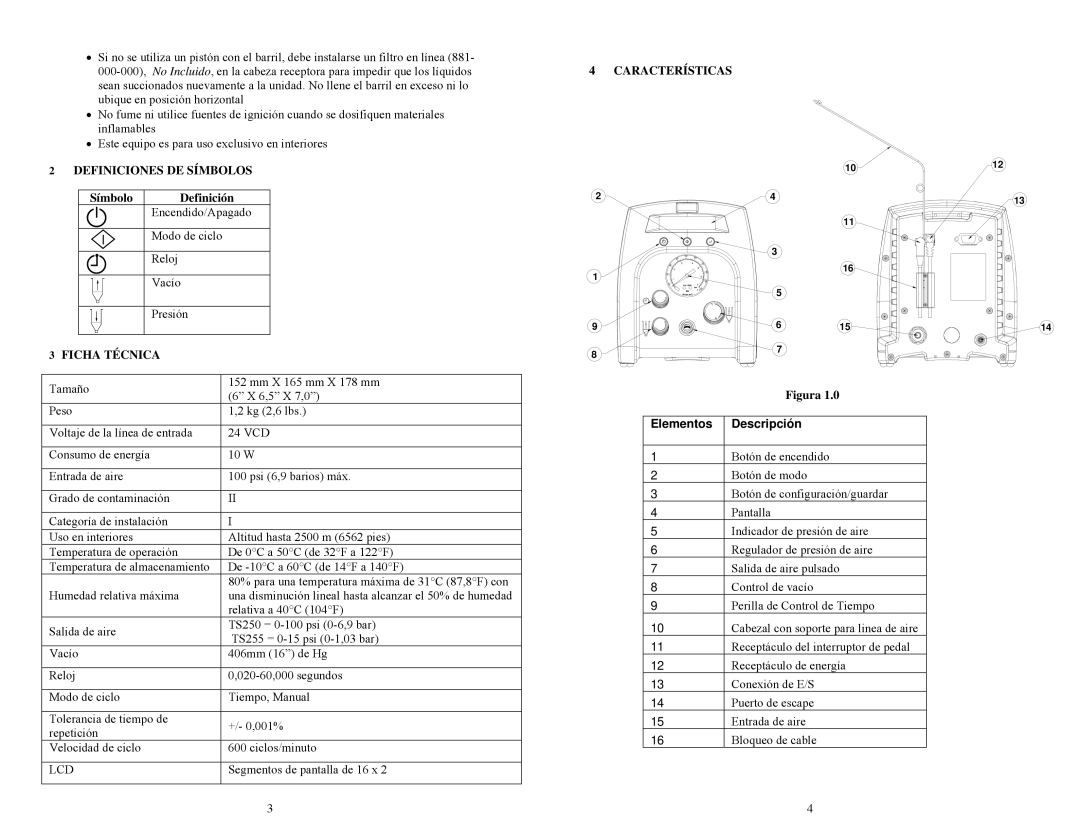

TS255, TS250 specifications

OK International has gained recognition for its innovative solutions in the field of soldering and rework systems, particularly with the introduction of the TS250 and TS255 models. These advanced tools cater to the needs of electronics manufacturers, providing efficiency and precision in soldering applications.The TS250 and TS255 are designed with user-friendliness in mind, featuring intuitive interfaces that allow operators to quickly adjust settings and configurations without extensive training. Both models are equipped with a powerful microprocessor control system, ensuring consistent temperature regulation and soldering performance. This thermoregulation not only enhances the quality of the solder joints but also extends the lifespan of the heating elements.

One of the standout features of the TS250 and TS255 is their fast heat-up times. These models are engineered to reach optimal operating temperatures in just seconds, reducing downtime in production environments. Coupled with a wide range of compatible soldering tips, users can easily switch from one application to another, allowing for versatility in various soldering tasks.

Additionally, both the TS250 and TS255 incorporate advanced airflow technology. This feature allows for precise control over air flow and temperature, which is particularly useful for sensitive electronic components that require careful handling. The built-in vacuum pump in the TS255 model provides effective desoldering capabilities, making it ideal for rework applications and repair tasks.

Ergonomics has also been a primary consideration in the design of these models. The lightweight construction, along with comfortable grip handles, minimizes operator fatigue during extended use. Furthermore, the units are equipped with built-in safety features, including an auto shut-off function to prevent overheating and potential damage to components.

In terms of connectivity, the TS250 and TS255 offer advanced options for integration with existing manufacturing systems. With the ability to connect to industry-standard interfaces, these tools can easily be incorporated into automated processes, providing seamless support for modern production lines.

In conclusion, the OK International TS250 and TS255 models represent a significant leap forward in soldering technology. With their advanced features, user-friendly design, and precise control systems, these tools are well-suited for both small-scale operations and large-scale manufacturing environments. Whether for assembly or rework, the TS250 and TS255 stand out as reliable solutions for achieving high-quality soldering outcomes.