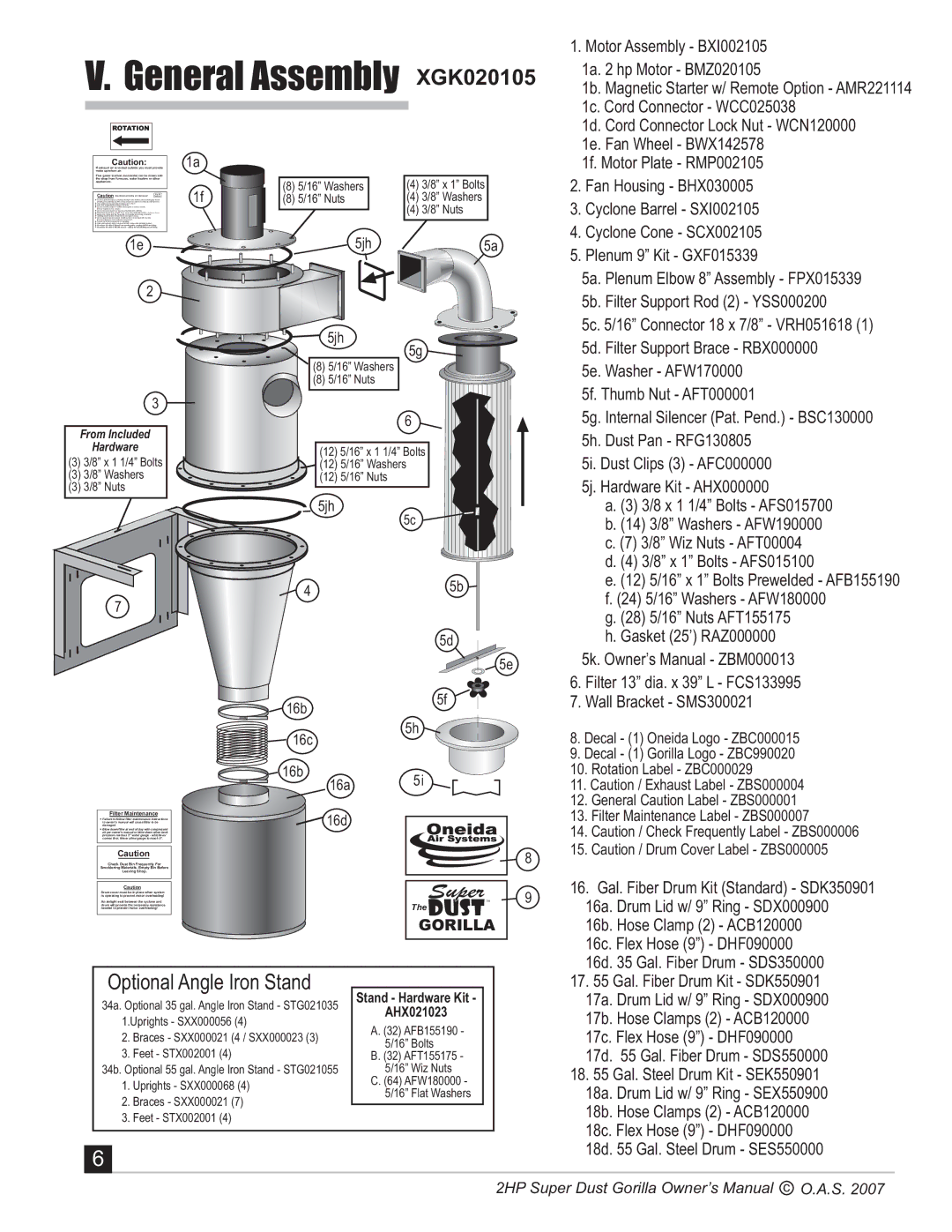

V. General Assembly XGK020105

1. Motor Assembly - BXI002105

1a. 2 hp Motor - BMZ020105

1b. Magnetic Starter w/ Remote Option - AMR221114

1c. Cord Connector - WCC025038

1d. Cord Connector Lock Nut - WCN120000

1e. Fan Wheel - BWX142578

Caution: |

|

| 1a |

If exhaust air is vented outside you must provide | |||

make up/return air. |

|

|

|

Flue gases (carbon monoxide) can be drawn into |

| ||

the shop from furnaces, water heaters or other |

| ||

appliances. |

|

|

|

|

|

| 1f |

|

|

| |

Caution Read Before Installing and Operating! | Systems |

| |

| For All |

| |

To avoid personal injury or property damage, read owner’s manual thoroughly before | |||

installing and operating system. (Read section on collector location and fire hazards.) | |||

This collector is for use with WOOD DUST ONLY! |

|

| |

Keep fire extinguishers handy at all times. |

|

| |

Do not use this product to collect other types of dusts or fumes. |

|

|

|

(Fire or explosion may occur!) |

|

|

|

Do not introduce sparks or sources of ignition into collector. |

|

|

|

Personnel should stay at least 20 ft. away from operating system. |

|

|

|

Empty and check dust bin frequently for possible smoldering materials. |

|

|

|

Rotating blades inside. Keep hands and objects away. |

|

|

|

Do not operate system unless COMPLETELY assembled with dustbin. |

|

|

|

(Personal injury or motor damage may occur!) |

|

|

|

Consult local fire marshal before installing. |

|

|

|

Follow all Federal, State, Local and NFPA codes when installing system. |

|

|

|

To reduce the risk of injury from moving parts - unplug before servicing. |

| ||

To reduce the risk of electric shock - unplug before cleaning or servicing. |

| ||

|

|

|

|

1e |

|

|

|

2 |

|

|

|

3

From Included

Hardware

(3) 3/8” x 1 1/4” Bolts

(3) 3/8” Washers

(3) 3/8” Nuts

7

Filter Maintenance

Failure to follow filter maintenance instructions in owner’s manual will cause filter to be damaged.

Blow down filter at end of day with compressed air per owner’s manual or blow down when back pressure reaches 3” water gauge - whichever comes first. Never allow gauge to reach 5”.

Caution

Check Dust Bin Frequently For

Smoldering Materials. Empty Bin Before

Leaving Shop.

Caution

Drum cover must be in place when system is operating to prevent motor overheating!

An airtight seal between the cyclone and drum will provide the necessary resistance needed to prevent motor overheating!

(8) | 5/16” Washers | (4) | 3/8” x 1” Bolts |

(8) | 5/16” Nuts | (4) | 3/8” Washers |

|

| (4) | 3/8” Nuts |

| 5jh |

| 5a |

5jh

5g

(8) 5/16” Washers

(8) 5/16” Nuts

6

(12)5/16” x 1 1/4” Bolts

(12)5/16” Washers

(12) 5/16” Nuts

| 5jh | 5c |

|

|

|

|

|

| |

4 |

|

| 5b |

|

|

|

| 5d |

|

|

|

|

| 5e |

16b |

|

| 5f |

|

|

|

|

| |

16c |

| 5h |

|

|

|

|

|

| |

16b | 16a | 5i |

|

|

|

|

| ||

|

|

|

| |

| 16d |

|

|

|

|

|

|

| 8 |

|

| The | TM | 9 |

|

|

|

|

GORILLA

1f. Motor Plate - RMP002105

2.Fan Housing - BHX030005

3.Cyclone Barrel - SXI002105

4.Cyclone Cone - SCX002105

5.Plenum 9” Kit - GXF015339

5a. Plenum Elbow 8” Assembly - FPX015339

5b. Filter Support Rod (2) - YSS000200

5c. 5/16” Connector 18 x 7/8” - VRH051618 (1)

5d. Filter Support Brace - RBX000000

5e. Washer - AFW170000

5f. Thumb Nut - AFT000001

5g. Internal Silencer (Pat. Pend.) - BSC130000

5h. Dust Pan - RFG130805

5i. Dust Clips (3) - AFC000000

5j. Hardware Kit - AHX000000

a. (3) 3/8 x 1 1/4” Bolts - AFS015700 b. (14) 3/8” Washers - AFW190000 c. (7) 3/8” Wiz Nuts - AFT00004

d. (4) 3/8” x 1” Bolts - AFS015100

e. (12) 5/16” x 1” Bolts Prewelded - AFB155190 f. (24) 5/16” Washers - AFW180000

g. (28) 5/16” Nuts AFT155175 h. Gasket (25’) RAZ000000

5k. Owner’s Manual - ZBM000013

6. Filter 13” dia. x 39” L - FCS133995 | |

7. Wall Bracket - SMS300021 | |

8. Decal - (1) Oneida Logo - ZBC000015 | |

9. Decal - (1) Gorilla Logo - ZBC990020 | |

10. | Rotation Label - ZBC000029 |

11. Caution / Exhaust Label - ZBS000004 | |

12. | General Caution Label - ZBS000001 |

13. | Filter Maintenance Label - ZBS000007 |

14. | Caution / Check Frequently Label - ZBS000006 |

15. | Caution / Drum Cover Label - ZBS000005 |

16. Gal. Fiber Drum Kit (Standard) - SDK350901 | |

16a. Drum Lid w/ 9” Ring - SDX000900 | |

16b. Hose Clamp (2) - ACB120000 | |

16c. Flex Hose (9”) - DHF090000 | |

16d. 35 Gal. Fiber Drum - SDS350000 | |

Optional Angle Iron Stand

34a. Optional 35 gal. Angle Iron Stand - STG021035 1.Uprights - SXX000056 (4)

2.Braces - SXX000021 (4 / SXX000023 (3)

3.Feet - STX002001 (4)

34b. Optional 55 gal. Angle Iron Stand - STG021055

1.Uprights - SXX000068 (4)

2.Braces - SXX000021 (7)

3.Feet - STX002001 (4)

Stand - Hardware Kit -

AHX021023

A. (32) AFB155190 -

5/16” Bolts

B. (32) AFT155175 -

5/16” Wiz Nuts

C. (64) AFW180000 -

5/16” Flat Washers

17. 55 Gal. Fiber Drum Kit - SDK550901 |

17a. Drum Lid w/ 9” Ring - SDX000900

17b. Hose Clamps (2) - ACB120000

17c. Flex Hose (9”) - DHF090000

17d. 55 Gal. Fiber Drum - SDS550000

18. 55 Gal. Steel Drum Kit - SEK550901 | |

18a. | Drum Lid w/ 9” Ring - SEX550900 |

18b. | Hose Clamps (2) - ACB120000 |

18c. Flex Hose (9”) - DHF090000 | |

6

18d. 55 Gal. Steel Drum - SES550000 |

2HP Super Dust Gorilla Owner’s Manual c O.A.S. 2007