ORBIT-6 RP-206 specifications

Orbit Manufacturing's ORBIT-6 RP-206 is a state-of-the-art device designed to meet the evolving demands of modern manufacturing processes. Known for its reliability and versatility, the ORBIT-6 RP-206 integrates advanced technologies that enhance operational efficiency and productivity across various industrial applications.One of the main features of the ORBIT-6 RP-206 is its robust construction, which ensures durability even in the most demanding environments. Built from high-grade materials, this equipment is designed to withstand wear and tear, thus reducing maintenance costs and downtime. The incorporation of a high-performance motor allows for improved power efficiency and faster processing speeds, enabling manufacturers to increase their output without sacrificing quality.

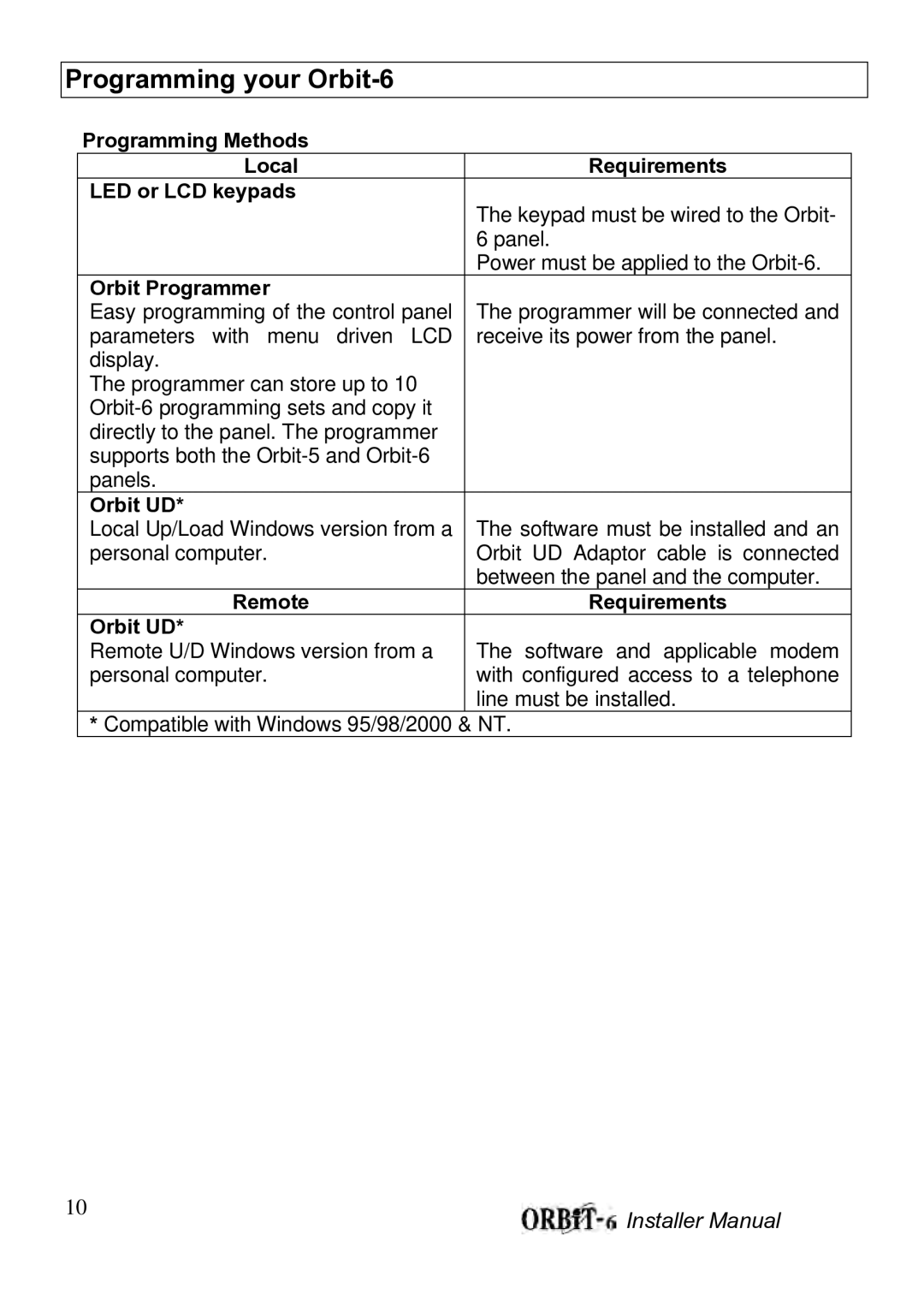

The ORBIT-6 RP-206 utilizes cutting-edge automation technologies. Equipped with a user-friendly interface, it allows for seamless integration into existing manufacturing systems. This system includes programmable features that enable users to customize operations according to their specific requirements. This flexibility makes it an ideal choice for small to medium-sized businesses as well as large-scale manufacturing facilities.

Moreover, one of the standout characteristics of the ORBIT-6 RP-206 is its advanced data analytics capabilities. By leveraging real-time data, manufacturers can continuously monitor performance metrics, allowing for proactive decision-making and process optimization. This feature not only enhances productivity but also contributes to quality control by identifying any deviations or anomalies during production.

Safety is another paramount concern for Orbit Manufacturing. The ORBIT-6 RP-206 incorporates various safety mechanisms, including automatic shut-off systems and emergency stops, ensuring a secure working environment for operators. Additionally, the machine is designed with easy access to key components for maintenance, further reinforcing its commitment to user safety and convenience.

In terms of environmental considerations, the ORBIT-6 RP-206 is engineered to minimize energy consumption and reduce waste. This eco-friendly approach resonates with the growing trend towards sustainable manufacturing practices, ensuring that businesses can meet their environmental goals while maintaining operational efficiency.

In conclusion, Orbit Manufacturing's ORBIT-6 RP-206 stands out as a technologically advanced solution for the modern manufacturing landscape. With its robust construction, automation capabilities, data analytics, safety features, and environmental consciousness, it is poised to deliver exceptional performance, making it an invaluable asset for any manufacturing operation.