Catalog | “N” Series Valves |

Technical Information | Technical Data |

|

|

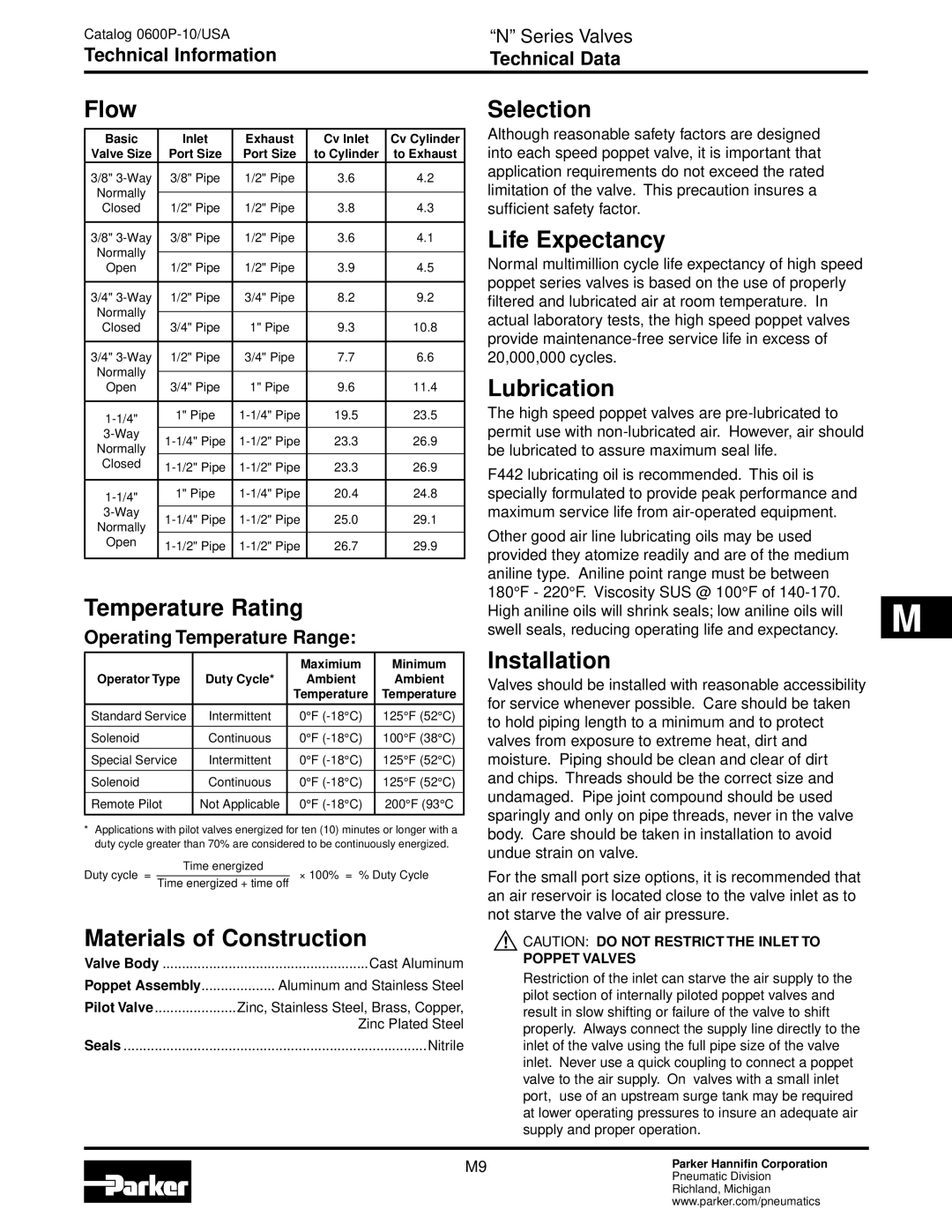

Flow

Basic | Inlet | Exhaust | Cv Inlet | Cv Cylinder | |

Valve Size | Port Size | Port Size | to Cylinder | to Exhaust | |

3/8" | 3/8" Pipe | 1/2" Pipe | 3.6 | 4.2 | |

Normally |

|

|

|

| |

|

|

|

| ||

Closed | 1/2" Pipe | 1/2" Pipe | 3.8 | 4.3 | |

|

|

|

|

| |

3/8" | 3/8" Pipe | 1/2" Pipe | 3.6 | 4.1 | |

Normally |

|

|

|

| |

|

|

|

| ||

Open | 1/2" Pipe | 1/2" Pipe | 3.9 | 4.5 | |

|

|

|

|

| |

3/4" | 1/2" Pipe | 3/4" Pipe | 8.2 | 9.2 | |

Normally |

|

|

|

| |

|

|

|

| ||

Closed | 3/4" Pipe | 1" Pipe | 9.3 | 10.8 | |

|

|

|

|

| |

3/4" | 1/2" Pipe | 3/4" Pipe | 7.7 | 6.6 | |

Normally |

|

|

|

| |

|

|

|

| ||

Open | 3/4" Pipe | 1" Pipe | 9.6 | 11.4 | |

|

|

|

|

| |

1" Pipe | 19.5 | 23.5 | |||

|

|

|

| ||

23.3 | 26.9 | ||||

Normally | |||||

|

|

|

| ||

Closed | 23.3 | 26.9 | |||

| |||||

|

|

|

|

| |

1" Pipe | 20.4 | 24.8 | |||

|

|

|

| ||

25.0 | 29.1 | ||||

Normally | |||||

|

|

|

| ||

Open | 26.7 | 29.9 | |||

| |||||

|

|

|

|

|

Temperature Rating

Operating Temperature Range:

|

| Maximium | Minimum |

Operator Type | Duty Cycle* | Ambient | Ambient |

|

| Temperature | Temperature |

|

|

|

|

Standard Service | Intermittent | 0°F | 125°F (52°C) |

|

|

|

|

Solenoid | Continuous | 0°F | 100°F (38°C) |

|

|

|

|

Special Service | Intermittent | 0°F | 125°F (52°C) |

|

|

|

|

Solenoid | Continuous | 0°F | 125°F (52°C) |

|

|

|

|

Remote Pilot | Not Applicable | 0°F | 200°F (93°C |

|

|

|

|

*Applications with pilot valves energized for ten (10) minutes or longer with a duty cycle greater than 70% are considered to be continuously energized.

Time energized

Duty cycle = Time energized + time off × 100% = % Duty Cycle

Selection

Although reasonable safety factors are designed into each speed poppet valve, it is important that application requirements do not exceed the rated limitation of the valve. This precaution insures a sufficient safety factor.

Life Expectancy

Normal multimillion cycle life expectancy of high speed poppet series valves is based on the use of properly filtered and lubricated air at room temperature. In actual laboratory tests, the high speed poppet valves provide

Lubrication

The high speed poppet valves are

F442 lubricating oil is recommended. This oil is specially formulated to provide peak performance and maximum service life from

Other good air line lubricating oils may be used provided they atomize readily and are of the medium aniline type. Aniline point range must be between 180°F - 220°F. Viscosity SUS @ 100°F of

Installation

Valves should be installed with reasonable accessibility for service whenever possible. Care should be taken to hold piping length to a minimum and to protect valves from exposure to extreme heat, dirt and moisture. Piping should be clean and clear of dirt and chips. Threads should be the correct size and undamaged. Pipe joint compound should be used sparingly and only on pipe threads, never in the valve body. Care should be taken in installation to avoid undue strain on valve.

For the small port size options, it is recommended that an air reservoir is located close to the valve inlet as to not starve the valve of air pressure.

M |

Materials of Construction | ! CAUTION: DO NOT RESTRICT THE INLET TO | ||

Valve Body | Cast Aluminum | POPPET VALVES | |

Restriction of the inlet can starve the air supply to the | |||

Poppet Assembly | Aluminum and Stainless Steel | ||

pilot section of internally piloted poppet valves and | |||

Pilot Valve | Zinc, Stainless Steel, Brass, Copper, | ||

result in slow shifting or failure of the valve to shift | |||

| Zinc Plated Steel | ||

| properly. Always connect the supply line directly to the | ||

|

| ||

Seals | Nitrile | inlet of the valve using the full pipe size of the valve | |

|

| inlet. Never use a quick coupling to connect a poppet | |

|

| valve to the air supply. On valves with a small inlet | |

|

| port, use of an upstream surge tank may be required | |

|

| at lower operating pressures to insure an adequate air | |

|

| supply and proper operation. | |

|

|

| |

| M9 | Parker Hannifin Corporation | |

|

| Pneumatic Division | |

Richland, Michigan

www.parker.com/pneumatics