TBIG-03 specifications

The Patterson-Kelley TBIG-03 is a cutting-edge boiler designed for commercial and industrial heating applications. Known for its robust construction and high efficiency, this model is popular among facility managers and engineers who prioritize reliability and performance.One of the standout features of the TBIG-03 is its ability to operate at high efficiencies exceeding 90%. This efficiency translates into significant fuel savings and reduced greenhouse gas emissions, making it an environmentally friendly choice for businesses looking to minimize their carbon footprint. The boiler utilizes advanced condensing technology, allowing it to capture and recycle heat from flue gases that would otherwise be lost.

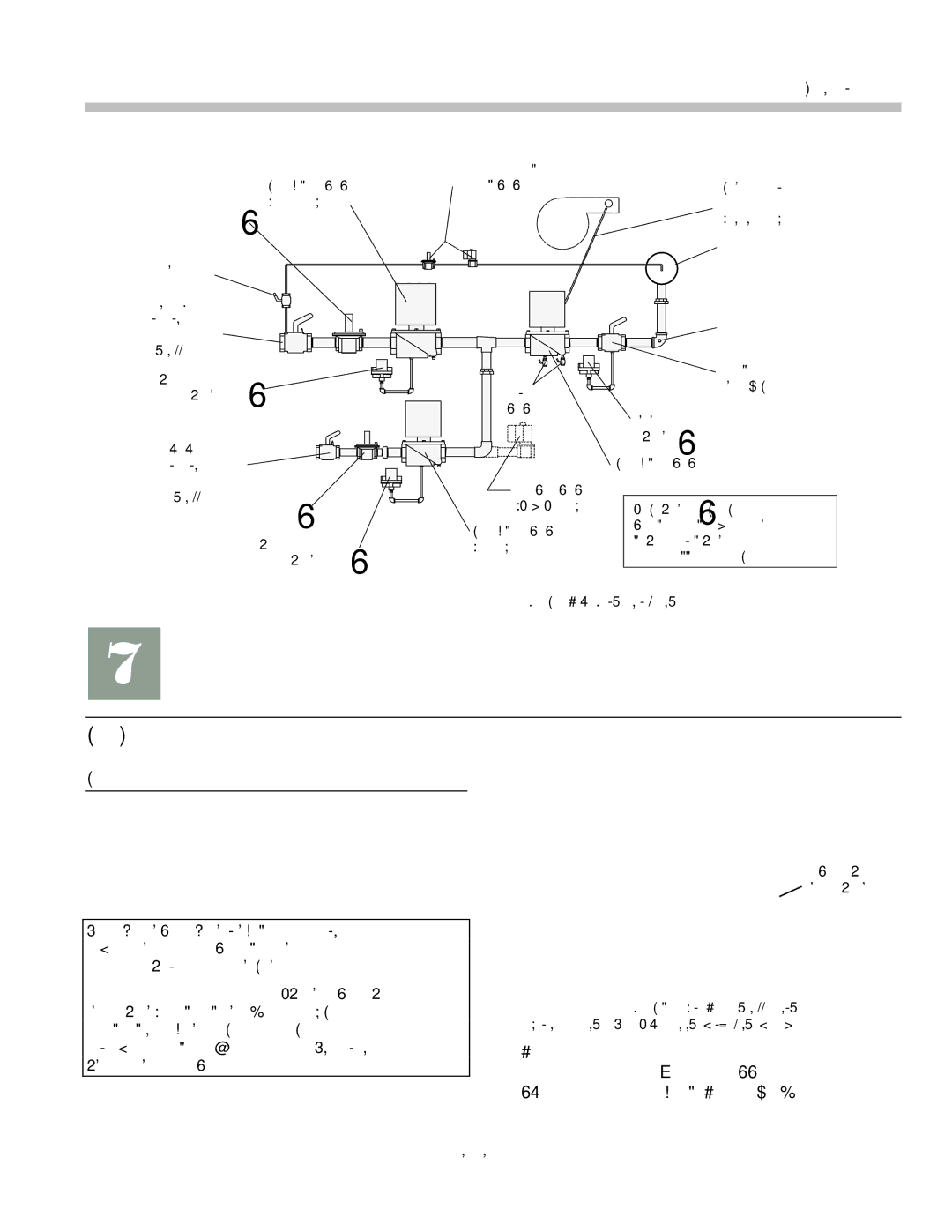

The TBIG-03 is equipped with a reliable control system that optimizes performance and enhances user control. The integrated digital display allows operators to monitor various parameters in real-time, ensuring that the system operates within optimal ranges. This not only improves the boiler's efficiency but also extends its lifespan by preventing unnecessary wear and tear.

Durability is another hallmark of the TBIG-03. Constructed with high-quality materials, including a stainless steel heat exchanger, this boiler is built to withstand the rigors of continuous operation. The heat exchanger is designed to facilitate quick heat transfer, further contributing to the unit’s efficiency and reliability.

Ease of maintenance is also a significant consideration in the design of the TBIG-03. With readily accessible components, service technicians can perform routine inspections and repair work with minimal downtime. This is a crucial factor for commercial operations, where system reliability is paramount.

Moreover, the TBIG-03 supports a variety of fuel options, including natural gas and propane, increasing its versatility across different applications. This adaptability allows facilities to choose the most cost-effective and resource-efficient fuel source available.

Overall, the Patterson-Kelley TBIG-03 stands out in the market due to its high efficiency, durability, and ease of use. Whether for heating large commercial spaces or industrial processes, this boiler meets the needs of modern enterprises seeking reliable and sustainable heating solutions. Its advanced features and technologies make it a top choice for efficiency-driven facility management.