9850, 7410 specifications

The Paxar 7410 and 9850 are advanced printing solutions tailored specifically for the needs of various industrial applications. Central to their appeal is the combination of speed, reliability, and high-quality output, making them ideal for industries such as retail, logistics, and manufacturing.One of the standout features of the Paxar 7410 is its impressive printing speed. Capable of producing labels and tags at a rapid pace, it significantly enhances workflow efficiency for businesses dealing with high-volume labeling tasks. This makes it particularly beneficial in environments where time is of the essence, such as shipping and inventory management.

The Paxar 9850, on the other hand, offers enhanced capabilities that expand its application range. It is known for its high-resolution printing, delivering crisp, clear graphics and text. This feature is essential for businesses that require intricate designs or barcodes that must be scanned reliably. The 9850’s ability to print with exceptional clarity reinforces its value in sectors like healthcare and pharmaceuticals where accurate labeling is critical.

Both models utilize advanced thermal transfer and direct thermal printing technologies. Thermal transfer printing involves the use of a ribbon that melts onto the label material, resulting in durable labels that resist fading and scratching. This is particularly useful for labels exposed to tough environments, ensuring longevity and legibility. Direct thermal printing, on the other hand, involves printing directly onto specially coated thermal paper, which can be a cost-effective solution for short-term labeling needs.

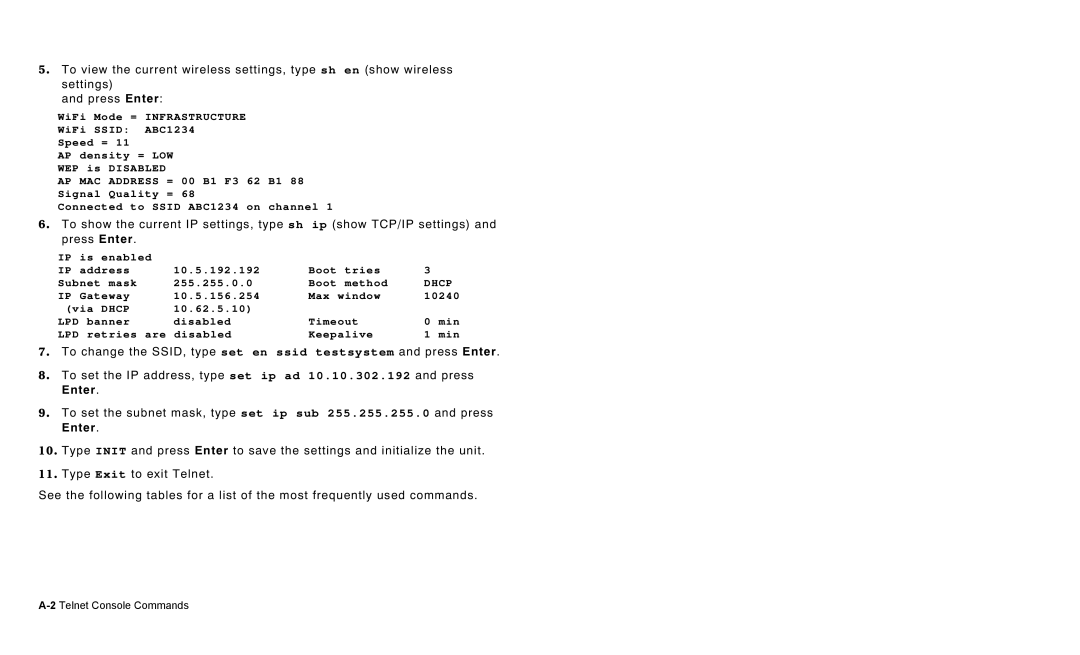

User-friendliness is another significant aspect of the Paxar printers. They are equipped with intuitive interfaces that allow for easy operation, reducing the learning curve for new users. Additionally, both models support multiple connectivity options, including USB and Ethernet, enabling seamless integration into existing systems and networks.

The robust design of the Paxar 7410 and 9850 ensures reliability and minimal downtime, crucial for operations that require continuous labeling without interruptions. Their durability makes them suited for demanding production environments where printers are frequently in use.

In conclusion, the Paxar 7410 and 9850 represent a blend of speed, precision, and user-friendly technology. Their design and functionality cater to the evolving needs of various industries, marking them as leaders in the realm of industrial printing solutions. With these printers, businesses can enhance their labeling processes, ensuring efficiency and high-quality outputs.