PIPING AND CONTROLS

3. PIPING AND CONTROLS

Do not pipe boiler before jacket is NOTICE installed.

A.PRESSURE TEST BLOCK ASSEMBLY

1.Make up cold water supply connection to the boiler.

2.Install pressure gauge or

3.Plug all open tappings in the boiler and fill with water. Apply approximately thirty (30) psig pressure. Check to make certain that all joints and fittings are water tight.

4.After all joints and connections have been proven tight, remove cold water supply and plugs from all tappings that are to be used. See Figures 7.1 and 7.2 (Section 7) for tapping locations.

B.BOILER RETURN CLEARANCE

Return piping must allow for opening and closing Burner Mounting Plate. PB Heat, LLC suggests installing a

C.WATER BOILER PIPING

1.Refer to the Water Installation Survey and Hydronics Institute Residential Hydronic Heating Installation/Design Guide for guidance.

2.The supply and return connections should be sized to suit the system. A

3.The supply should be out the top of the back section and return to the bottom of the front section as shown in Figure 3.1. There is a 3/4" tapping in the top of the back section for air elimination.

Figure 3.1: Water Boiler Piping

4.When the return temperature from the system will be below 150°F on oil boilers for extended periods (heat pump systems, outdoor reset, snow melt, etc.), provide piping and controls to protect the boiler from condensation. Condensation will damage the boiler and will lead to shortened boiler life and maintenance problems.

5.If using a Partner indirect fired water heater or other, see Figure 3.6 for typical piping. Also refer to additional instructions supplied with the Partner.

6.If the boiler is to be used in conjunction with a refrigeration system, the chilled medium shall be piped in parallel with boiler and proper valves applied to prevent the chilled medium from entering the boiler. Refer to Figure 3.5.

7.If the boiler is connected to heating coils located in air handling units, the boiler piping system must be equipped with flow control valves or other automatic devices to prevent gravity circulation of the boiler water during the cooling cycle.

D.STEAM BOILER PIPING

1.Refer to the Steam Installation Survey and Hydronics Institute Residential Hydronic Heating Installation/Design Guide for assistance.

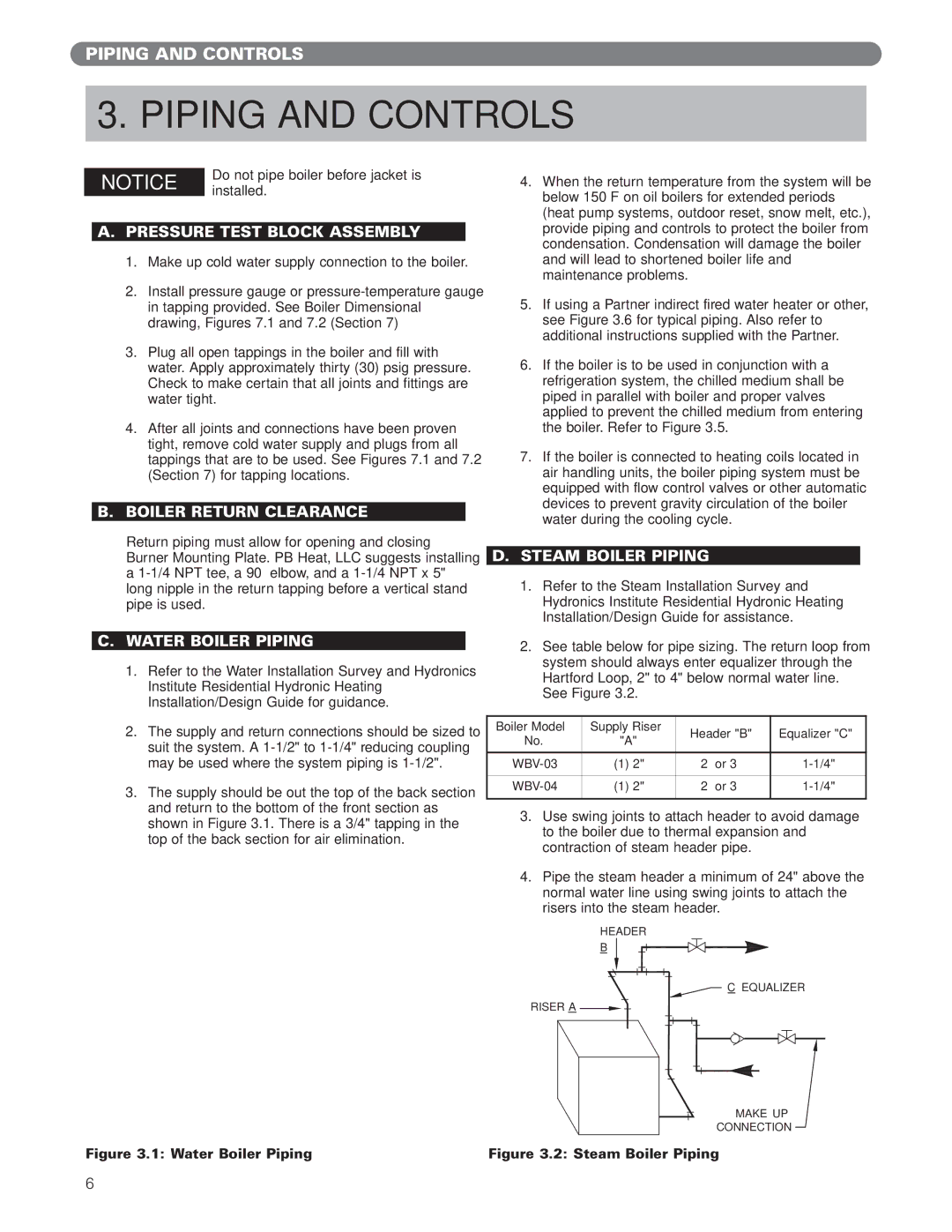

2.See table below for pipe sizing. The return loop from system should always enter equalizer through the Hartford Loop, 2" to 4" below normal water line. See Figure 3.2.

Boiler Model | Supply Riser | Header "B" | Equalizer "C" | |

No. | "A" | |||

|

| |||

|

|

|

| |

(1) 2" | 2” or 3” | |||

|

|

|

| |

(1) 2" | 2” or 3” | |||

|

|

|

|

3.Use swing joints to attach header to avoid damage to the boiler due to thermal expansion and contraction of steam header pipe.

4.Pipe the steam header a minimum of 24" above the normal water line using swing joints to attach the risers into the steam header.

HEADER

B

![]() C EQUALIZER

C EQUALIZER

RISER A ![]()

![]()

CONNECTION

Figure 3.2: Steam Boiler Piping

6