![]() WARNING

WARNING

•Tighten screws so adapter brackets are firmly attached. Do not tighten with excessive force. Overtightening can cause stress damage to screws, greatly reducing their holding power and possibly causing screw heads to become detached. Tighten to 40 in. • lb (4.5 N.M.) maximum torque.

•If screws don't get three complete turns in the screen inserts or if screws bottom out and bracket is still not tightly secured, damage may occur to screen or product may fail.

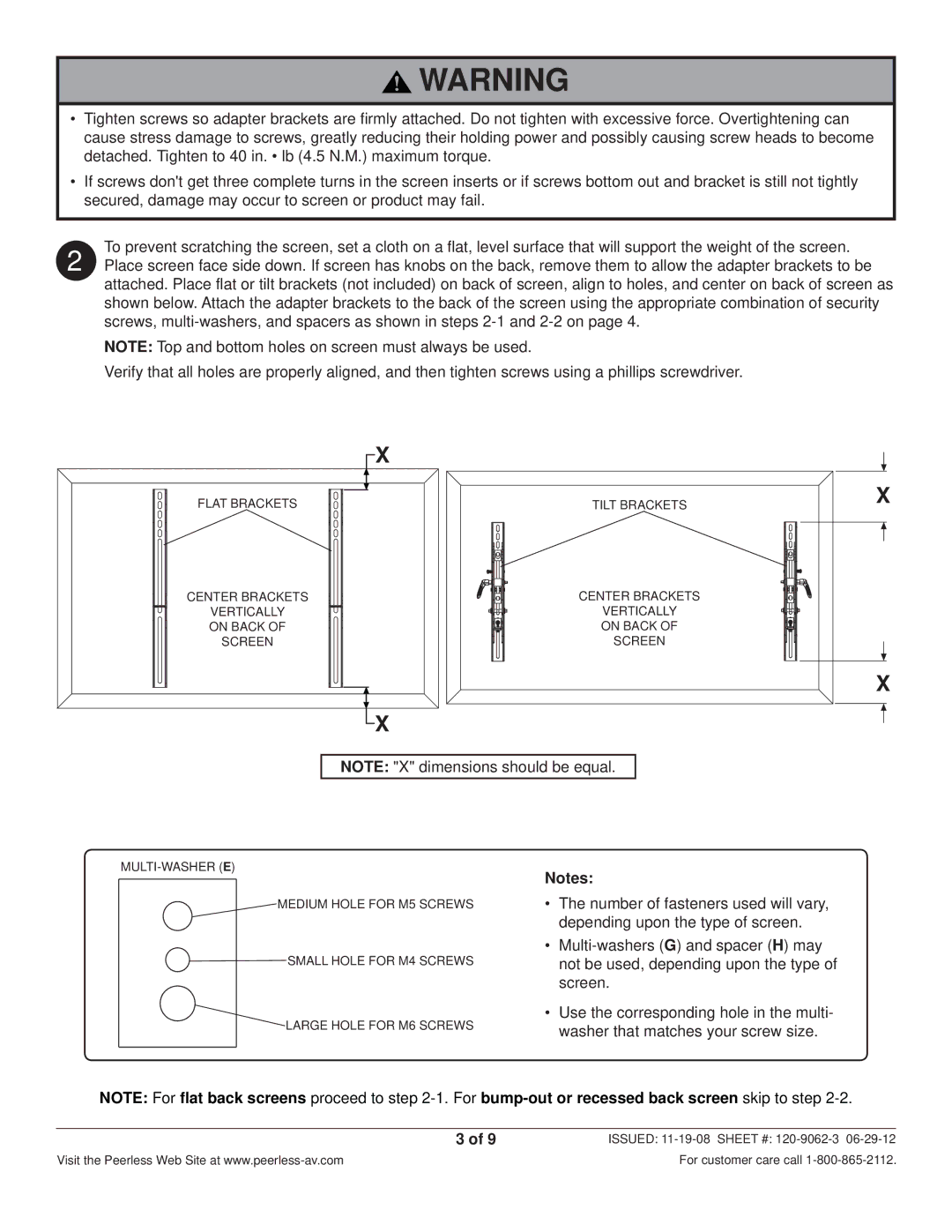

2 | To prevent scratching the screen, set a cloth on a flat, level surface that will support the weight of the screen. |

Place screen face side down. If screen has knobs on the back, remove them to allow the adapter brackets to be |

attached. Place flat or tilt brackets (not included) on back of screen, align to holes, and center on back of screen as shown below. Attach the adapter brackets to the back of the screen using the appropriate combination of security screws,

NOTE: Top and bottom holes on screen must always be used.

Verify that all holes are properly aligned, and then tighten screws using a phillips screwdriver.

![]() X

X

FLAT BRACKETS

CENTER BRACKETS

VERTICALLY

ON BACK OF

SCREEN

![]() X

X

TILT BRACKETS | X |

CENTER BRACKETS |

|

VERTICALLY |

|

ON BACK OF |

|

SCREEN |

|

| X |

NOTE: "X" dimensions should be equal.

MEDIUM HOLE FOR M5 SCREWS

![]() SMALL HOLE FOR M4 SCREWS

SMALL HOLE FOR M4 SCREWS

![]() LARGE HOLE FOR M6 SCREWS

LARGE HOLE FOR M6 SCREWS

Notes:

•The number of fasteners used will vary, depending upon the type of screen.

•

•Use the corresponding hole in the multi- washer that matches your screw size.

NOTE: For flat back screens proceed to step

3 of 9 | ISSUED: |

Visit the Peerless Web Site at | For customer care call |