Installation (Gas Line) |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 14 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

GAS CONNECTIONS | Pipe Sized For Length Of Run In Equivalent Feet | Table 1. | ||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

GAS LINE INSTALLATIONS |

|

| 1/2 in. | 3/4 in. | 1 in. | 1¼ in. | 1½ in. |

| 2 in. | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Model |

| Nat |

| LP | Nat | LP | Nat | LP | Nat | LP | Nat | LP |

| Nat |

| LP | ||

Before installing the gas line, be sure to |

|

|

|

| ||||||||||||||

200 |

| - |

| 20' | 30' | 80' | 125' | 250' | 450' | 600' | - | - |

| - |

| - | ||

check which gas the heater has been |

|

|

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

designed to burn. This is important | 250 |

| - |

| 10' | 20' | 50' | 70' | 150' | 250' | 500' | 600' | - |

| - |

| - | |

because different types of gas require | 300 |

| - |

| - | 10' | 30' | 50' | 100' | 200' | 350' | 400' | 600' |

| - |

| - | |

different gas pipe sizes. The rating plate | 400 |

| - |

| - | - | 10' | 20' | 60' | 100' | 150' | 200' | 450' |

| 400' |

| - | |

on the heater will indicate which gas the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

heater is designed to burn. Table 1, shows which |

| REGULATED MANIFOLD PRESSURE TEST |

| |||||||||||||||

size pipe is required for the distance from the gas |

|

| ||||||||||||||||

| 1. Attach the manometer to the heater jacket. |

|

|

| ||||||||||||||

meter to the heater. The table is for natural gas at a |

|

|

|

| ||||||||||||||

| 2. Shut off the main gas valve. |

|

|

|

|

|

| |||||||||||

specific gravity of .65. |

|

|

| 3. Remove 1/8 in. NPT plug on the outlet side of the |

| |||||||||||||

When sizing gas lines, calculate three (3) additional |

|

| valve and screw in the fitting from the manometer kit. | |||||||||||||||

| 4. Connect the manometer hose to the fitting. |

|

|

| ||||||||||||||

feet of straight pipe for every elbow used. |

|

|

|

|

|

| ||||||||||||

|

|

| 5. Turn on the heater. |

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

When installing the gas line, avoid getting dirt, |

| 6. The manometer must read 4 in. WC for natural gas, | ||||||||||||||||

|

| while operating. |

|

|

|

|

|

|

|

|

| |||||||

grease or other foreign material in the pipe as this |

|

|

|

|

|

|

|

|

|

|

| |||||||

| 7. For adjustment, remove the Regulator Adjustment | |||||||||||||||||

may cause damage to the gas valve, which may |

| |||||||||||||||||

|

| Cap and using a screwdriver turn the screw clock- | ||||||||||||||||

result in heater failure. |

|

|

|

| ||||||||||||||

|

|

|

| wise to increase - counterclockwise to decrease gas | ||||||||||||||

The gas meter should be checked to make sure that |

|

| pressure. |

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

it will supply enough gas to the heater and any other |

|

|

|

|

|

|

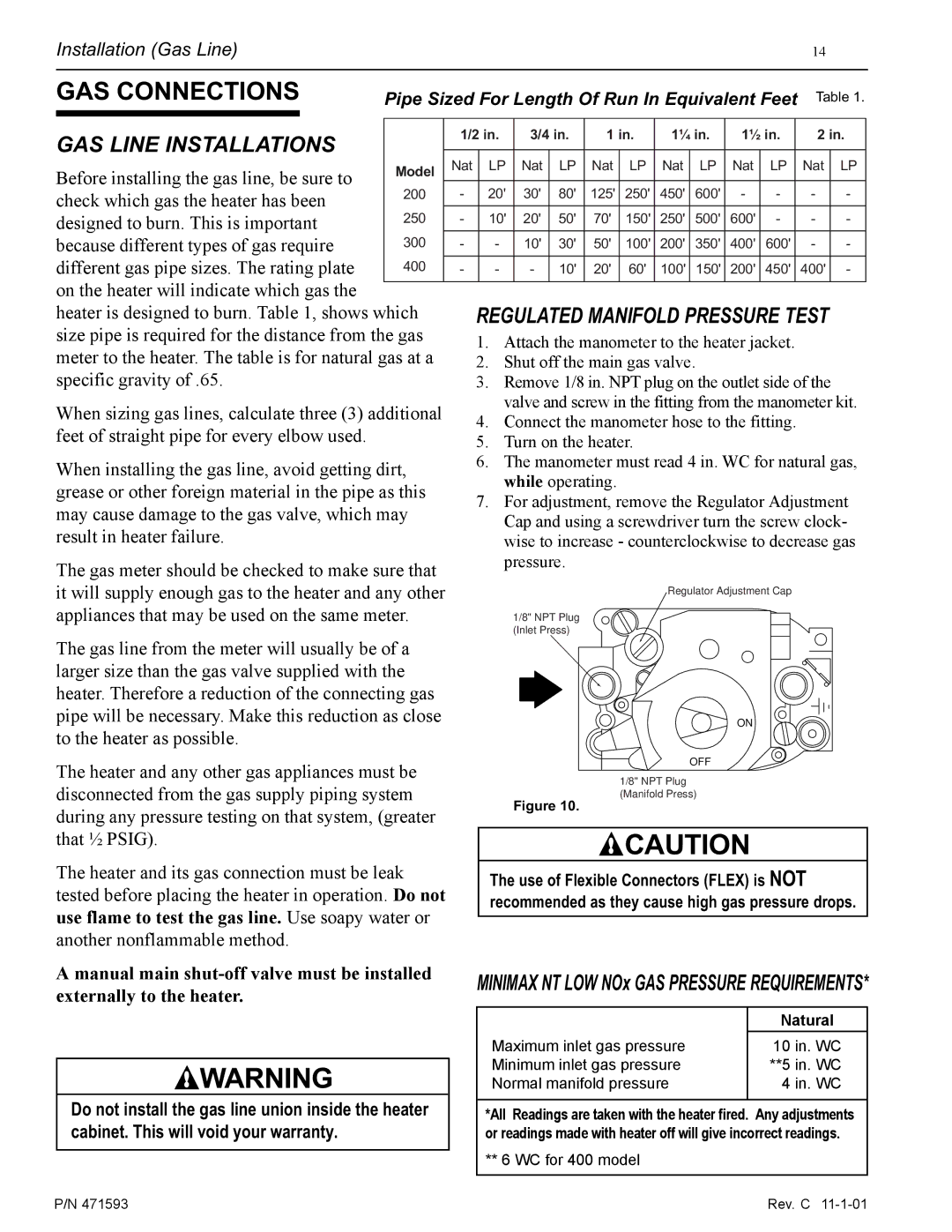

| Regulator Adjustment Cap |

|

|

| |||||||

appliances that may be used on the same meter. |

|

|

| 1/8" NPT Plug |

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

| (Inlet Press) |

|

|

|

|

|

|

|

|

|

| |

The gas line from the meter will usually be of a larger size than the gas valve supplied with the heater. Therefore a reduction of the connecting gas pipe will be necessary. Make this reduction as close to the heater as possible.

ON

The heater and any other gas appliances must be disconnected from the gas supply piping system during any pressure testing on that system, (greater that ½ PSIG).

The heater and its gas connection must be leak tested before placing the heater in operation. Do not use flame to test the gas line. Use soapy water or another nonflammable method.

OFF

1/8" NPT Plug

(Manifold Press)

Figure 10.

![]() CAUTION

CAUTION

The use of Flexible Connectors (FLEX) is NOT recommended as they cause high gas pressure drops.

A manual main

![]() WARNING

WARNING

Do not install the gas line union inside the heater cabinet. This will void your warranty.

MINIMAX NT LOW NOx GAS PRESSURE REQUIREMENTS*

|

| Natural |

| Maximum inlet gas pressure | 10 in. WC |

| Minimum inlet gas pressure | **5 in. WC |

| Normal manifold pressure | 4 in. WC |

|

|

|

*All Readings are taken with the heater fired. Any adjustments or readings made with heater off will give incorrect readings.

** 6 WC for 400 model

P/N 471593 | Rev. C |