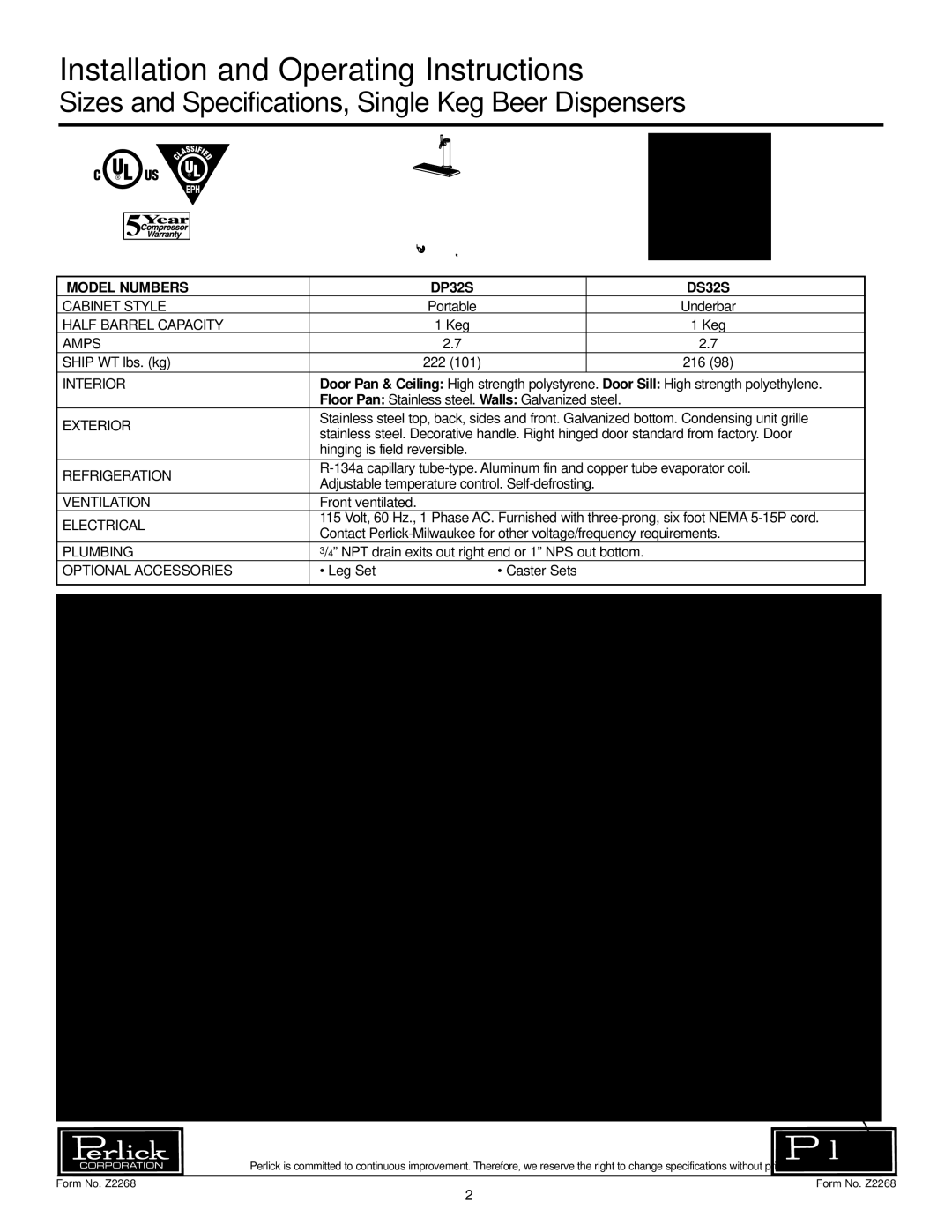

DS32S, DP32S specifications

The Perlick DP32S and DS32S represent some of the finest offerings in the world of commercial refrigeration and beverage dispensing. These models are designed with a keen focus on efficiency, durability, and performance, making them an ideal choice for bars, restaurants, and any establishment that prioritizes quality beverage service.One of the standout features of the DP32S and DS32S is their dual-zone design. This allows for separate temperature controls, enabling users to store different types of beverages at their optimal temperature. The models are equipped with advanced digital temperature controls that allow for precise adjustments and monitoring, which is essential for maintaining the quality of craft beers, wines, and other beverages.

Constructed with high-grade stainless steel, these units are built to last. Their robust design not only ensures longevity but also simplifies cleaning and maintenance, thus ensuring a hygienic storage environment for beverages. The smooth finish is resistant to fingerprints and smudges, catering to aesthetic appeal in front-of-house applications.

Both models come with a self-closing door feature, which is designed to reduce the risk of temperature fluctuations caused by open doors. This is enhanced by magnetic door seals that create a tight fit, ensuring energy efficiency while minimizing operational costs.

In addition to temperature control, the DP32S and DS32S boast a high-capacity refrigeration system. This technology allows for quick recovery times, ensuring that your beverages remain at the ideal temperature even during peak service periods. Moreover, these models are designed with energy-efficient components, which can lead to significant savings in energy costs over time.

Another important characteristic is their generous storage capacity. The DP32S and DS32S can accommodate a variety of keg sizes, making them versatile options for establishments that serve multiple beverage types. Adjustable shelving and storage configurations further enhance their usability.

Finally, both models are engineered for exceptional performance. The cooling systems are designed to distribute cold air evenly throughout the cabinet, preventing hot spots and ensuring that every beverage is consistently chilled.

Overall, the Perlick DP32S and DS32S are exemplary choices for any commercial setting looking for reliable, stylish, and functionally superior beverage storage solutions. With their advanced technology and durable design, they stand out as investments that pay dividends in both performance and service quality.